ENGINE

6-10

3TNV88F Service Manual

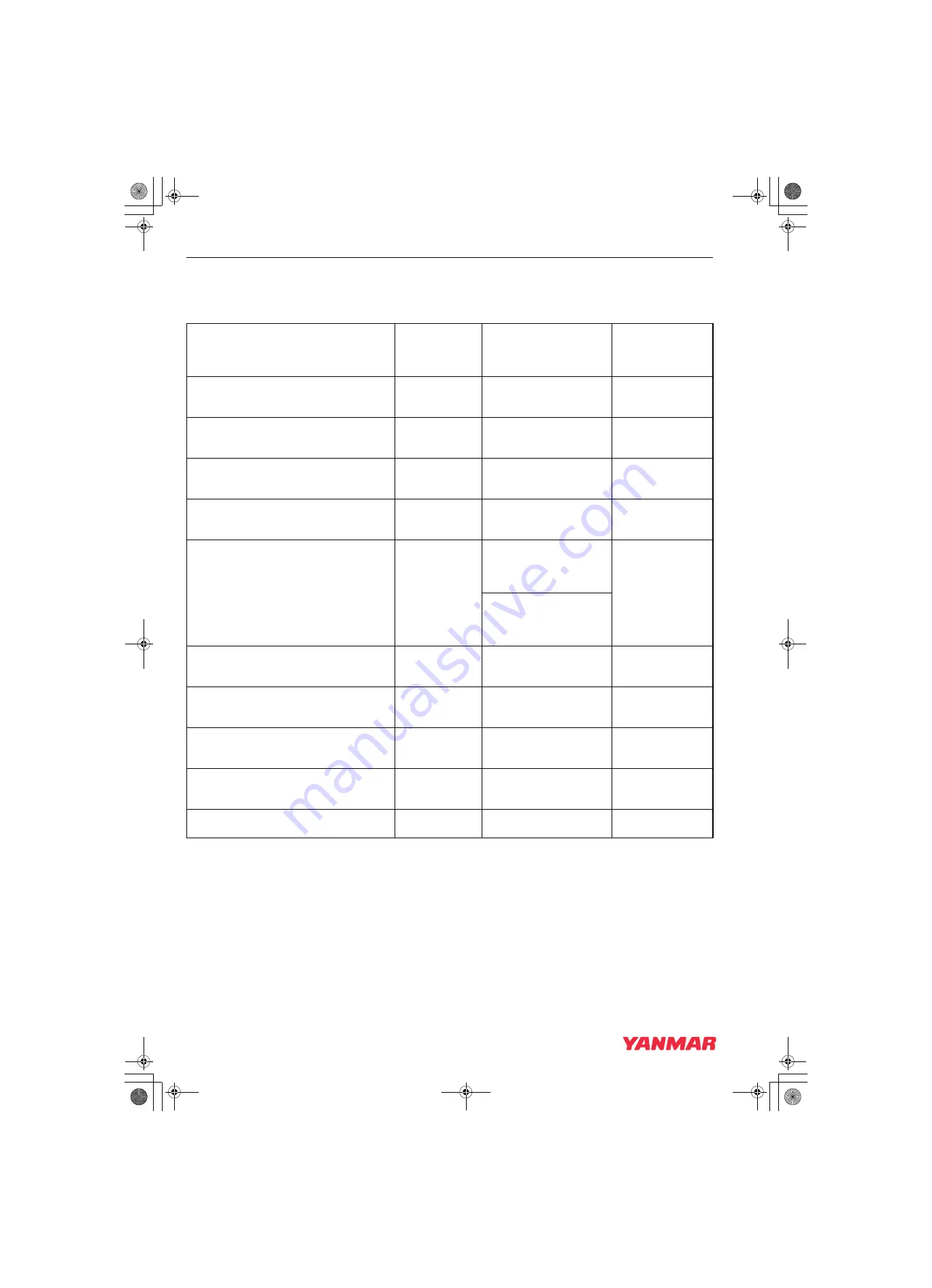

Special Torque Chart

SPECIAL TORQUE CHART

Torque for Bolts and Nuts

Note: See Tightening Torques for Standard Bolts and Nuts on page 4-25 for standard hardware torque

values.

Component

Thread

diameter and

pitch

Torque

Lubricating oil

application

(thread portion and

seat surface)

Cylinder head bolt

M10 × 1.25 mm

63 - 67 ft·lb

(85.3 - 91.1 N·m;

8.7 - 9.3 kgf·m)

Applied

Connecting rod bolt

M9 × 1.0 mm

33 - 36 ft·lb

(44.1 - 49.0 N·m;

4.5 - 5.0 kgf·m)

Applied

Flywheel bolt

M10 × 1.25 mm

61 - 65 ft·lb

(83.3 - 88.2 N·m;

8.5 - 9.0 kgf·m)

Applied

Main bearing cap bolt

M12 × 1.5 mm

69 - 72 ft·lb

(93.2 - 98.1 N·m;

9.5 - 10.5 kgf·m)

Applied

Crankshaft pulley bolt

M14 × 1.5 mm

Cast metal (FC300)

62 - 69 ft·lb

(83.3 - 93.1 N·m;

8.5 - 9.5 kgf·m)

Applied

Steel metal (S45C)

83 - 91 ft·lb

(112.7 - 122.7 N·m;

11.5 - 12.5 kgf·m)

Fuel injector bolt

M8 × 1.25 mm

18 - 21 ft·lb

(24.4 - 28.4 N·m;

2.5 - 2.9 kgf·m)

Not applied

Fuel pump drive gear nut

M14 × 1.5 mm

58 - 65 ft·lb

(78 - 88 N·m;

8 - 9 kgf·m)

Not applied

High-pressure fuel lines bolt

M12 × 1.5 mm

22 - 25 ft·lb

(29.4 - 34.3 N·m;

3.0 - 3.5 kgf·m)

Not applied

Glow plug

M10 × 1.25 mm

133 - 177 in·lb

(15 - 20 N·m

1.53 - 2.04 kgf·m)

Not applied

Glow connector nut

M4 × 0.7 mm

9 - 13 in·lb

(1 - 1.5 N·m)

Not applied

3TNV88F_SVM_A4.book 10 ページ 2012年7月26日 木曜日 午後6時4分