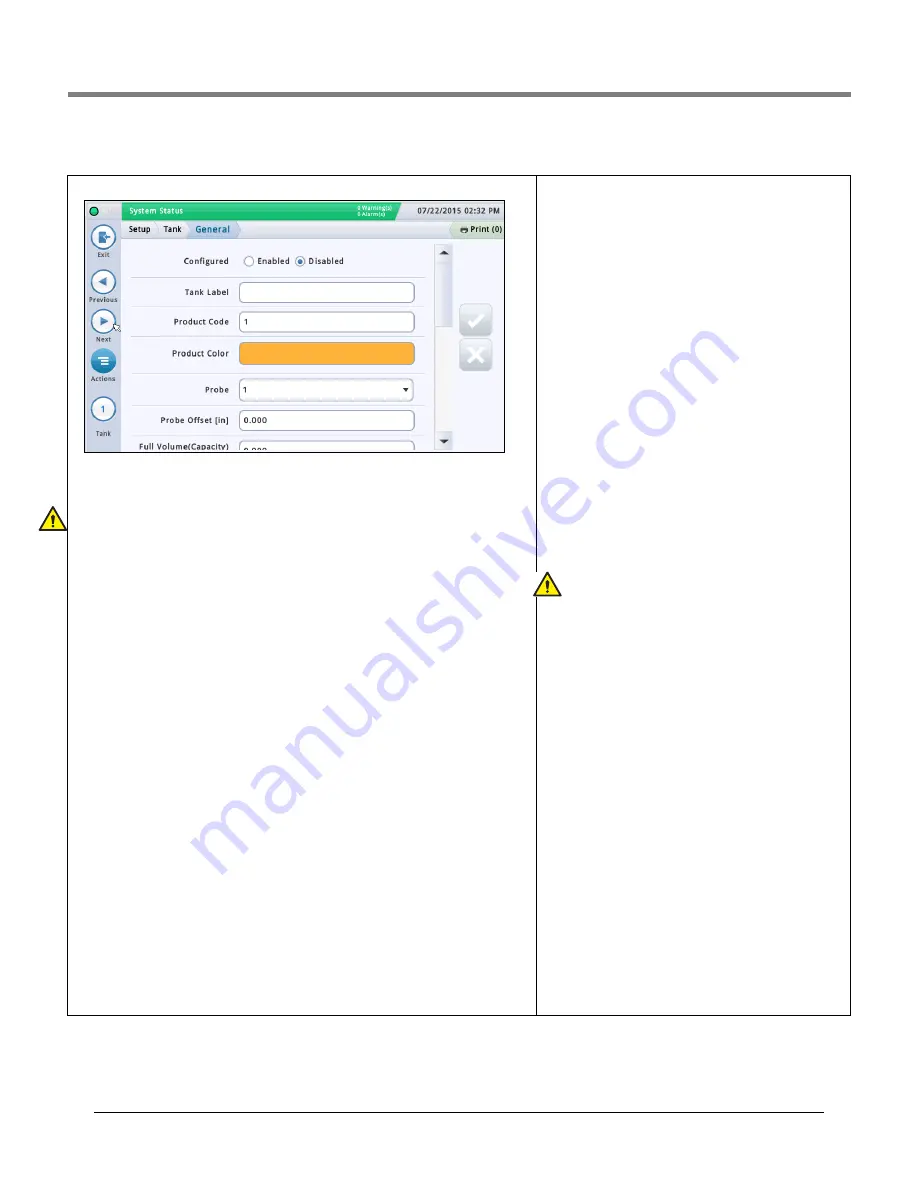

Initial Setup Of The Console Using Workflow Wizard

Setup>Tank>General

26

Setup>Tank>General

Configured

Touch the radio button to enable or disable the tank.

NOTE: Set to Enabled only after co

m

pleting all of the Setup>Tank screens.

Label

Touch to enter a description for the tank (nor

m

ally based on the na

m

e of the product in the

tank and should be unique for each tank).

NOTE: This field is not the sa

m

e as the label associated with the product, which is assigned

in the

Setup > Product > Labels

screen.

Product Code

Touch to enter an alphanu

m

eric code for a POS ter

m

inal used to identify the product for

inventory control purposes. This typically defaults to the corresponding tank nu

m

ber, such as

T1 and PC 1.

NOTE: There are instances when you

m

ay want to override the default value provided and

enter a different code. For exa

m

ple, in BIR, you

m

ay have two tanks that have the sa

m

e

product type. In this case, you would want to progra

m

the sa

m

e product code the for each

tank. By

m

anually entering in the correct code, you would ensure BIR is presenting the cor-

rect data for the product type..

Product Color

Touch and select a color that represents this product when displayed on screen.

Probe

Touch to enter an Identifier of the installed probe (as set up in “Setup>Devices”). A probe

assign

m

ent to a tank is one to one:

• Probe 1 is assigned to tank 1

• Probe 2 is assigned to tank 2

• etc.

Probe Offset

The probe offset value is the distance the probe is off the botto

m

of the tank and helps to

obtain an accurate

m

easure

m

ent of fuel in the tank.

In console calculations, the probe offset value is always added to the product height value

when product height is displayed (for exa

m

ple, in Overview>Tank Detail).

Touch to enter a value co

m

pensating for probes that are not resting on the botto

m

of the

tank.

Full Volume (Capacity)

Touch to enter the full volu

m

e of the tank at 100% height

(this volu

m

e is provided by the tank

m

anufacturer).

Diameter

Touch to enter the inside dia

m

eter of the tank (look for this

di

m

ension on the tank chart provided by the

m

anufacturer).

Tank Tilt

Touch to enter the a

m

ount of offset (in inches [

mm

]) of the

tank fro

m

a perfect horizontal. For an explanation of tank tilt

and how to calculate this value, see Actions>Help>Refer-

ence Tables>Tank Tilt Calculation.

NOTES:

• If the probe is installed in the center of the tank, enter a

value of 0.00.

• Tank Tilt

m

ay be a positive (+) or negative (-) value. If it is

a negative value,

m

ake sure to change the value sy

m

bol to

m

inus (-) when entering a negative tank tilt value.

Thermal Coefficient

Touch to enter a value representing the coefficient of ther-

m

al expansion for the fuel in the tank. This value provides

the proper expansion and contraction rate for a particular

product type. If this value is entered incorrectly, it i

m

pacts

inventory and tank test results. For a list of ther

m

al coeffi-

cients, see Actions>Help> Reference Tables>Ther

m

al

Coefficients.

NOTE:

Make sure you enter the correct value. If you

are off by one deci

m

al point, it can substantially affect

syste

m

calculations.

Meter Data Present

For the selected tank, touch the radio button to enable or

disable BIR software

*

to collect dispenser transaction data

fro

m

the

m

eters. (Note: BIR

m

onitors data only fro

m

tanks

assigned to Mag probes 1 to 32).

NOTE: Do not enable unless the Veeder-Root electronic Dis-

penser Interface Module (DIM) or current loop Dispenser

Interface Module (DIM) are connected properly to the con-

sole.

*

BIR option required

Pump Threshold %

[Field enabled when using line

m

anifolded tanks and the

Dispense Mode field is set to ‘Manifolded:Sequential’ in

“Setup>Pu

When the tank volu

m

e drops below the pu

m

p threshold per-

centage entered in this field, pu

m

ping will switch over i

mm

e-

diately to the next available tank in the line-

m

anifolded line.

Pu

m

ping will continue fro

m

the current tank for another 10

seconds to avoid a disruption in any dispenser during the

switch-over.