22

UBI EasyCoder 501 – Technical Manual

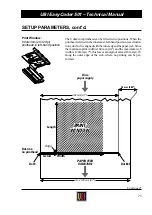

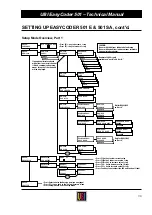

SETUP PARAMETERS, cont'd.

The Detection facilities are used to adjust the label stop/black mark

sensor (LSS) and to control the paper feed.

LSS Adjustment:

The LSS is a photo-electric detection device that controls the paper

feed. Situated inside the printing mechanism, it detects the front

edges of the labels, slits in tickets or tags, or the rear edges of black

marks on the back side of the paper web.

If the printer is set up for “Label (w gaps)”, “Ticket (w gaps)”, “Fix

length strip”, or “Var. length strip”, a narrow beam of light is

emitted from the upper part of the LSS and received by the sensor

in the lower part. Non-transparent paper will block the beam

completely, whereas semi-transparent backing paper between la-

bels will allow some of the light to pass through. A detection gap in

the ticket web causes no interference at all. An out-of-paper

condition is assumed, when no interference to the beam has been

detected within a feed length corresponding to the distance between

the dot line on the printhead and the sensor.

When the printer is set up for “Ticket (w mark)”, the light is emitted

from the lower part of the LSS. The beam can be reflected back to

the receiver by the white paper at the back of the web. If the beam

hits a black mark, practically no light will be reflected back . An out-

of-paper condition is assumed, when no reflected light has been

detected within a feed length corresponding to the distance between

the dot line on the printhead and the sensor.

Obviously, it is important that the printer is set up for the correct type

of media (see “Media Type” later in this chapter) so the firmware

can interpret the signals correctly.

The LSS can be moved max. 50 mm sideways across the web. The

inner edge of the handle indicates the lateral position of the sensor.

The LSS is automatically fine-adjusted when a Testfeed operation

is performed. Moreover, the LSS emitters can be adjusted in regard

of light intensity in the Setup Mode or by means of setup files and

the LSS receiver can be adjusted by means of a potentiometer on the

CPU board (see the chapter “Electronics/Potentiometers”).

If the printer works as expected, there is no need to adjust the LSS,

but if the printer starts to feed out labels or tickets in an unexpected

manner, check that the sensor is properly aligned in relation to the

web and that it has not become dirty. Perform a few Testfeed

operations to allow the sensor to auto-adjust itself.

If the error remains, proceed according to the description of the

Setup Mode for the printer model in question. Only as a last resort

should the potentiometer be adjusted.

Continued!

Detection

• LSS Adjustment

• Feed Adjustment

Emitter and

Receiver

Emitter

The upper part of the LSS is a light emitter

for labels, tickets and strip, whereas the

lower part contains both a receiver and

an emitter for black mark detection.

Handle

The inner edge of the handle indicates the

position of the LSS.

Note!

Printers fitted with a ribbon save device

have different type of label stop/black

mark sensor mechanism, where the

lateral position of the sensor is adjusted

by means of a screw instead of a handle,

see chapter “Ribbon Save Device” later

in this manual.

Содержание EasyCoder 501

Страница 106: ...106 UBI EasyCoder 501 Technical Manual NOTES...