Inspection and Reconditioning (Rev 1/97)

53

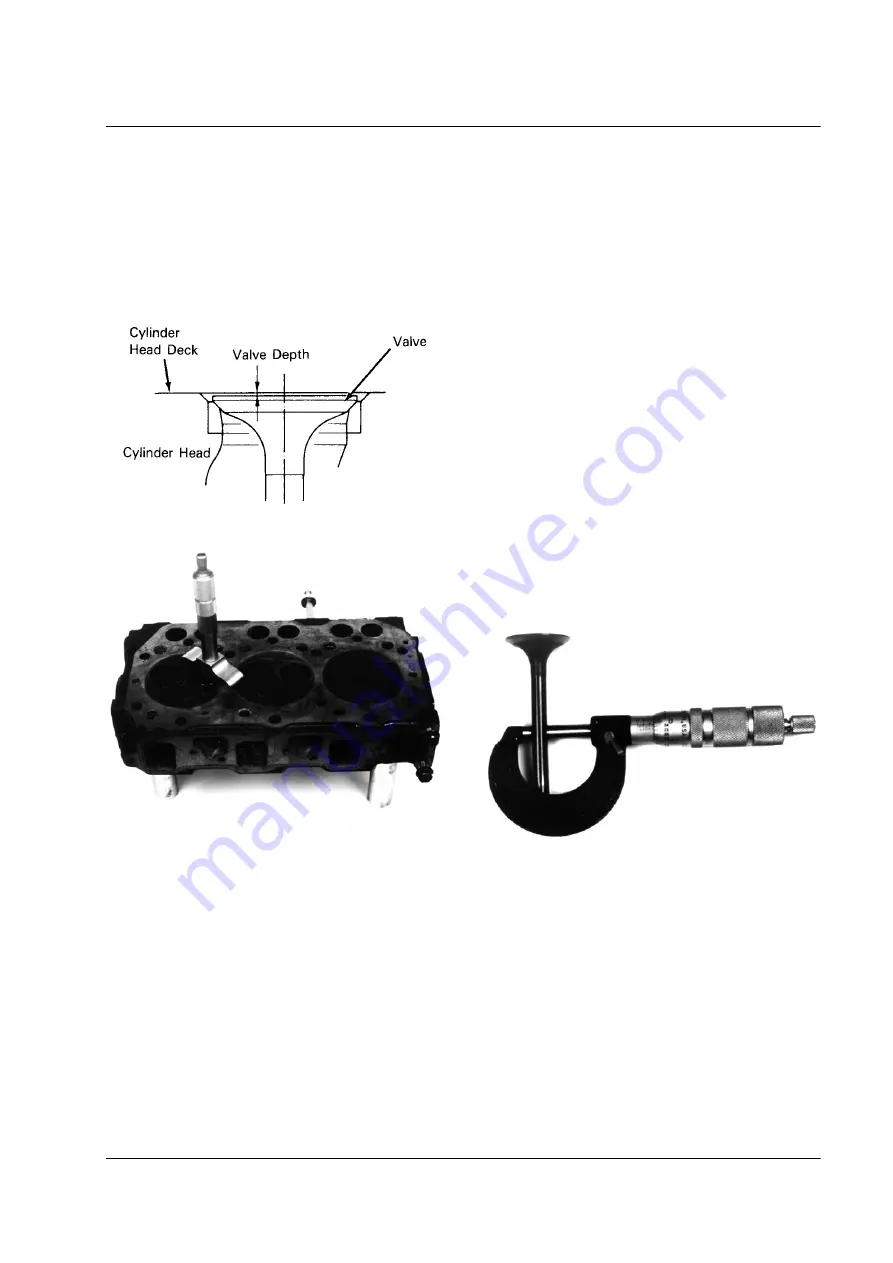

Valve Depth

The valve depth is the distance between the cylinder head

deck and the valve.

Valve Depth

Measuring Valve Depth

The valve depth is a critical dimension for most diesel

engines. Grinding the valve or the valve seat increases the

valve depth. As the valve depth increases, the volume of the

combustion chamber also increases and the compression

ratio decreases. Decreasing the compression ratio can cause

hard starting or poor performance. Therefore it is very

important to check the valve depth of each valve before and

after grinding the valve, and before and after grinding the

valve seat. If the valve depth is near the wear limit before

aea260

aea261

grinding the valve or valve seat, the valve, the valve seat or

both may need replacement. If the valve depth is over the

wear limit after grinding the valve or the valve seat, the

valve, the valve seat or both must be replaced.

To check the valve depth, install the valves in their respec-

tive valve seats and measure the valve depth of each with a

depth gauge or a caliper. The wear limit for both the intake

and exhaust valves in all of these engines is .039 in. (1.00

mm).

Valves

1. Clean and inspect the valves. Replace valves that are

cracked, bent, or have valve faces that are significantly

damaged.

2. Measure the outside diameter of the valve stems. If the

valve stem is smaller than the wear limit (refer to Spec-

ifications), replace the valve.

Measuring Valve Stem

3. The valves can be ground to clean up any wear or

minor damage on the valve faces. Grind the valves until

all signs of wear or damage are removed. Grind the

valve faces to the following angles:

Intake 30

degrees

Exhaust

45 degrees

aea262