Fuel System (Rev 1/97)

88

4. With the engine running in high speed, check the

engine speed and adjust as necessary for that particular

unit.

5. With the engine running in high speed, turn the maxi-

mum speed stop screw in (clockwise) until it touches

the governor linkage. The engine speed will decrease

and you will feel resistance when the maximum speed

stop screw begins to contact the governor linkage. Back

the maximum speed stop screw out one turn from the

point where it first touches the governor linkage.

6. Lock the maximum speed stop screw in this position

with the jam nut, replace the cap nut, and install a new

lead seal.

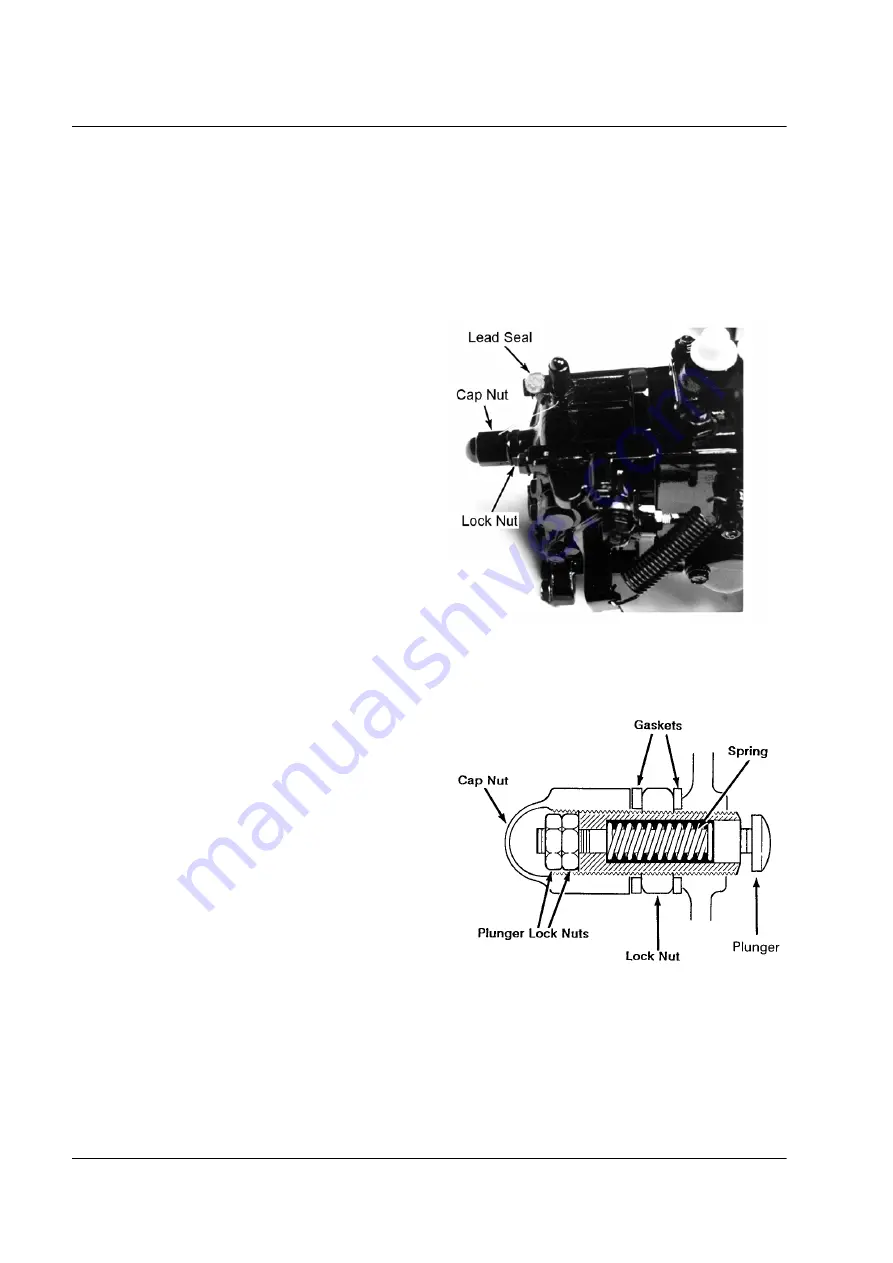

Fuel Limit Screw Adjustment

NOTE: The fuel limit screw is covered with an anti-

tamper cap and is not adjustable on later model engines.

The fuel limit screw is located on the end of the injection

pump governor housing, which faces toward the flywheel.

The fuel limit screw is set when the injection pump is cali-

brated at the factory and SHOULD NOT be adjusted unless

there is reason to believe someone has tampered with it.

Evidence that the fuel adjustment screw has been moved

includes a damaged or missing lead seal, an engine that has

difficulty picking up speed, or an engine that emits exces-

sive amounts of black smoke when the engine changes

speed. Use the following procedure to adjust the fuel limit

screw.

NOTE: Two adjustments are required to adjust the fuel

limit screw properly. First the fuel limit screw assembly

must be removed from the governor housing to adjust the

plunger clearance. The fuel limit screw assembly can then

be replaced and adjusted correctly.

Adjust Plunger Clearance

1. Remove the lead seal and the cap nut from the fuel

adjustment screw.

Fuel Limit Screw Location

2. Loosen the lock nut and remove the fuel limit screw

assembly from the governor housing.

Fuel Limit Screw Assembly

aea336

aea337