Inspection and Reconditioning (Rev 1/97)

49

3. Measure the inside diameter of the connecting rod bear-

ings. If any of the connecting rod bearings are larger

than the wear limits (refer to Specifications) or show

significant damage, replace the entire set of connecting

rod bearing inserts.

4. Check each connecting rod bearing bore by installing

the rod caps with the rod bearing inserts removed and

properly torquing the rod cap bolts (refer to Specifica-

tions).

5. Measure each connecting rod bearing bore both parallel

and perpendicular to the rod. If the rod bearing bore is

more than .001 in. (0.25 mm) out of round the rod must

be reconditioned or replaced.

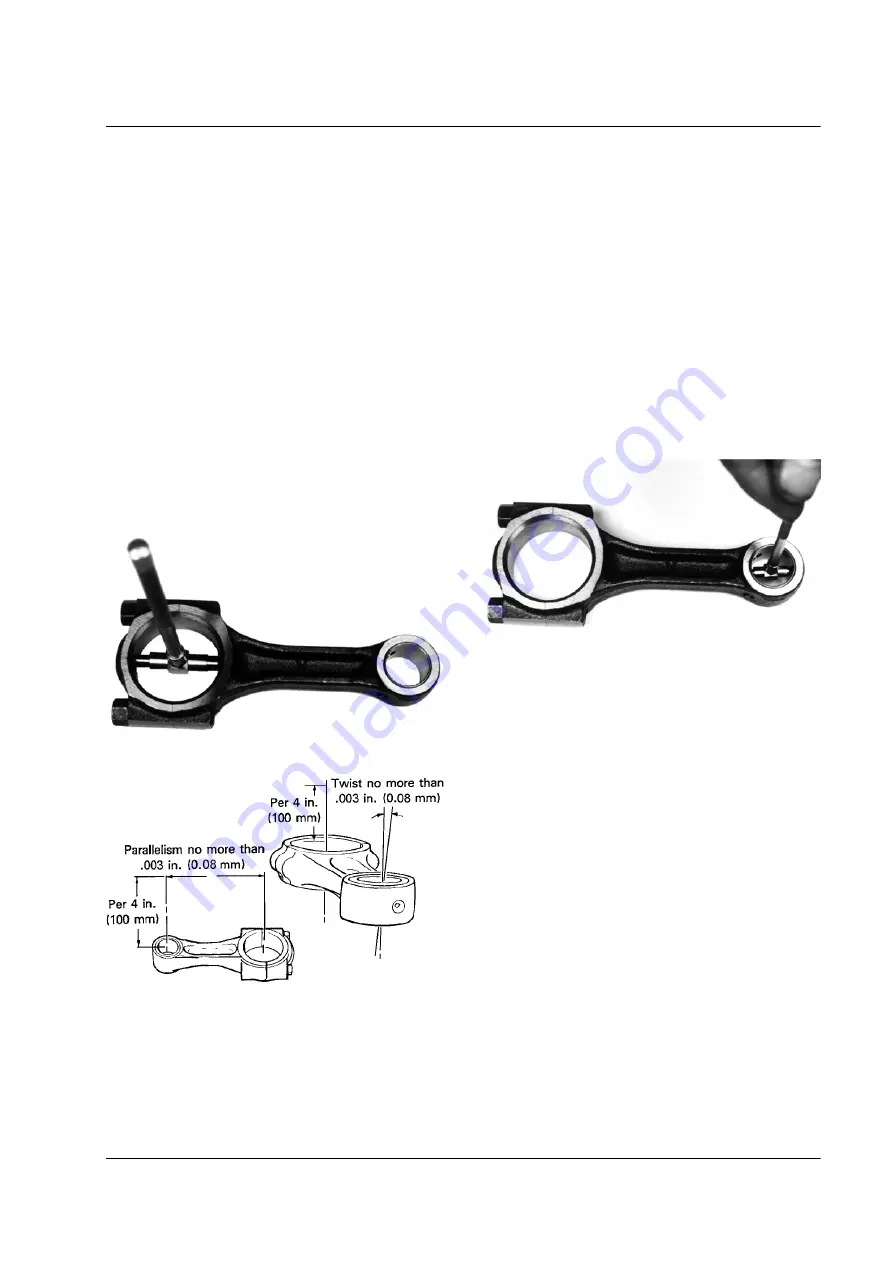

Measuring Rod Bearing Bore

Measuring Connecting Rod Twist and Parallelism

aea249

aea248

6. Use a connecting rod alignment fixture to check each

rod for twist and parallelism. The service limit for both

twist and parallelism is .003 in. per 4 in. (0.08 mm per

100 mm). If the twist or parallelism exceeds the wear

limit, straighten or replace the rod.

7. Measure the inside diameter of the connecting rod

bushings. If the connecting rod bushings are larger than

the wear limits (refer to Specifications) or show signifi-

cant damage, replace the connecting rod bushings.

Measuring Rod Bushing

8. To replace a connecting rod bushing, press the old

bushing out of the connecting rod. Press the new bush-

ing into the rod and make sure to align the oil hole in

the bushing with the oil hole in the top of the rod.

9. Finish the new bushing by reaming or honing it to size.

Each connecting rod bushing must be sized to its indi-

vidual wrist pin. Measure the outside diameter of the

wrist pin. Adding the suggested oil clearance of .0010-

.0019 in. (0.025-0.047 mm) to the outside diameter of

the wrist pin results in the correct inside diameter for

the finished connecting rod bushing.

aea250