Fuel System (Rev 1/97)

86

The electric fuel pump pressurizes the fuel to approximately

10 psi (69 kPa) and forces the fuel through the fuel filter to

the injection pump. The injection pump forces the fuel, at a

very high pressure, through the injection nozzles. The injec-

tion nozzles atomize the fuel as it is injected indirectly into

the combustion chambers through the prechambers.

The system uses a Bosch in-line injection pump. The injec-

tion pump camshaft is driven at one end by the engine’s tim-

ing gears. The cam lobes actuate the plungers, which force

fuel through the injection nozzles. A governor assembly is

connected to the other end of the injection pump camshaft.

The governor meters the amount of fuel delivered to the

injection nozzles by controlling the position of the plungers.

The fuel system is relatively trouble free and, if properly

maintained, does not usually require major service or repair

between engine overhauls.

The most common cause of problems in the fuel system is

contamination. The fuel must be clean, the fuel tanks must

be free of contaminants, and the fuel filters must be changed

regularly. Any time the fuel system is opened, all possible

precautions must be taken to keep dirt from entering the

system. All fuel lines must be capped when disconnected.

The work should be done in a relatively clean area and the

work should be completed in the shortest time possible.

Thermo King recommends that any major injection pump or

nozzle repairs be done by a qualified diesel injection service

shop. The investment in equipment and facilities to service

these components is quite high. Therefore, this equipment is

not found in most repair shops.

The following procedures can be done under field condi-

tions:

1. Bleeding air from the fuel system.

2. Maintenance of the fuel tank and fuel filter system.

3. Speed adjustments.

4. Electric fuel pump repair or replacement.

5. Injection line replacement.

6. Injection pump timing and minor repair.

7. Injection nozzle testing, adjustment, and minor repair.

Bleeding Air From The Fuel System

Air usually gets into the fuel system when the engine runs

out of fuel or if repairs are made to the fuel system.

NOTE: Be sure to keep the vent in the fuel tank open. If

the vent becomes clogged, a partial vacuum develops in

the fuel tank. This increases the chance that air will enter

the fuel system.

Use the following procedure to bleed air out of the fuel

system.

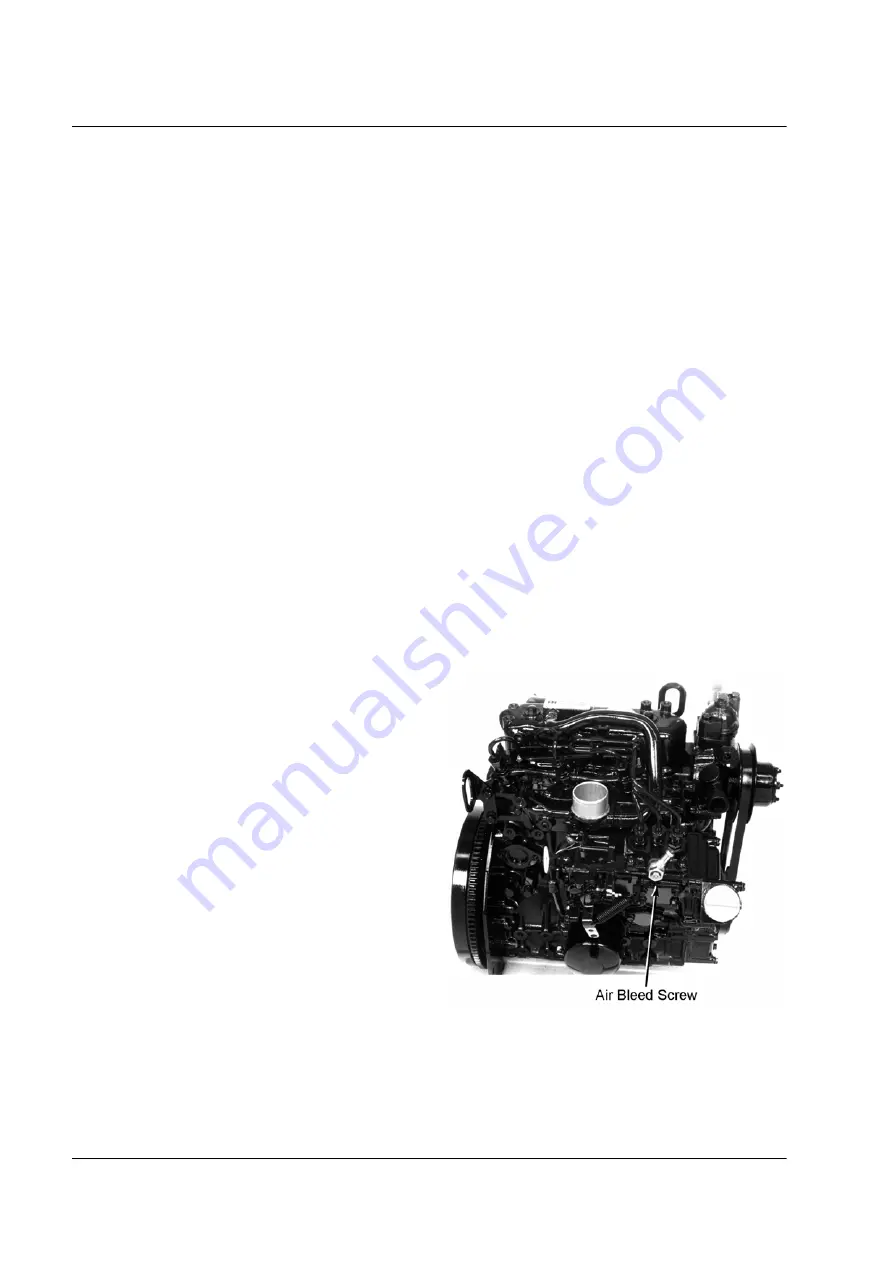

1. Loosen the air bleed screw or the inlet fitting on the

injection pump.

Air Bleed Screw Location

aea332