65

Engine Assembly

Assembly Precautions

NOTE: Refer to the Specifications section for specifica-

tions not given in this section.

After the components of the engine have been repaired,

reconditioned, or replaced, the engine can bee assembled. It

is very important to keep the engine as clean as possible

while it is being assembled, because dirt is one of the major

factors that contributes to the failure of rebuilt engines. To

avoid problems, take these precautions:

1. Do not assemble the engine in an area where any type

of grinding is done.

2. Keep your workbench, tools, and hands clean.

3. Keep sub-assemblies covered until they are needed.

4. If the engine must be left, even for a short period of

time, cover the engine until you return.

5. Make sure to follow the sequence of assembly exactly.

If certain parts are not installed in the correct order, the

engine may require some disassembly to install these

parts properly.

6. Check all the assembly tolerances such as bearing

clearance, end play, and gear lash carefully. Neglecting

these tolerances can cause serious reliability problems

in a rebuilt engine.

Assembly Procedure

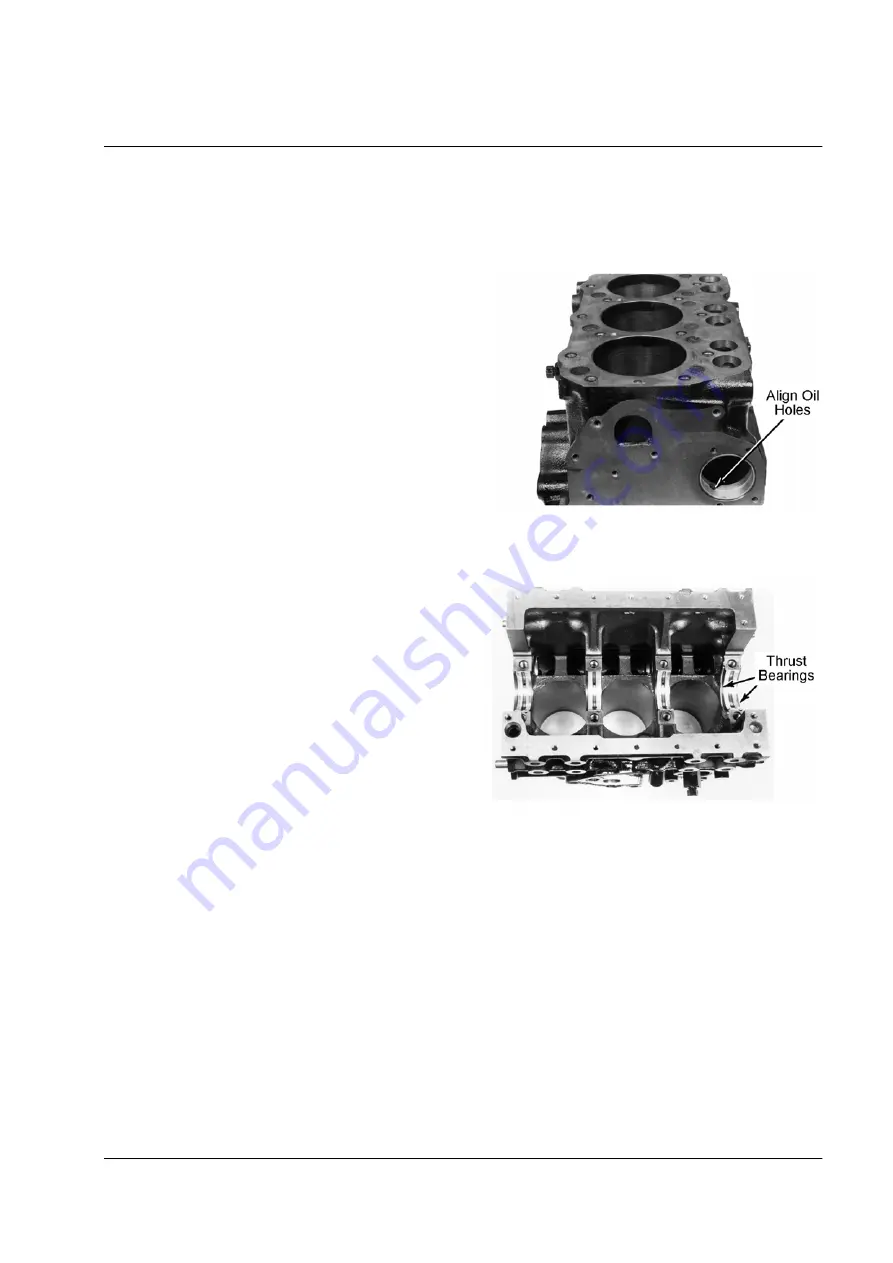

1. Install the front camshaft bearing insert using a bearing

driver. Make sure the oil holes in the bearing insert line

up with the oil holes in the front camshaft bearing bore.

2. Install or check all of the oil gallery and core plugs.

3. Place the new upper main bearing inserts in the cylin-

der block. The upper main bearing inserts are identical

and have oil holes and oil groves in them. Make sure

the holes in the bearing inserts line up with the holes in

the main bearing bores.

Install Camshaft Bearing

Install Upper Main Bearings

4. Place the upper thrust bearings in position on each side

of the upper rear main bearing. The grooves on the

thrust bearings should face away from the upper rear

main bearing.

aea286

aea287