Inspection and Reconditioning (Rev 1/97)

59

2. Place each push rod on a completely flat surface and

use a feeler gauge to check the how much the push rod

is bent. Replace any push rod that is bent more than

.003 in. (0.075 mm).

3. Measure the length of each push rod. Replace any Push

Rods that are shorter than the minimum standard

dimension (refer to Specifications).

Tappets

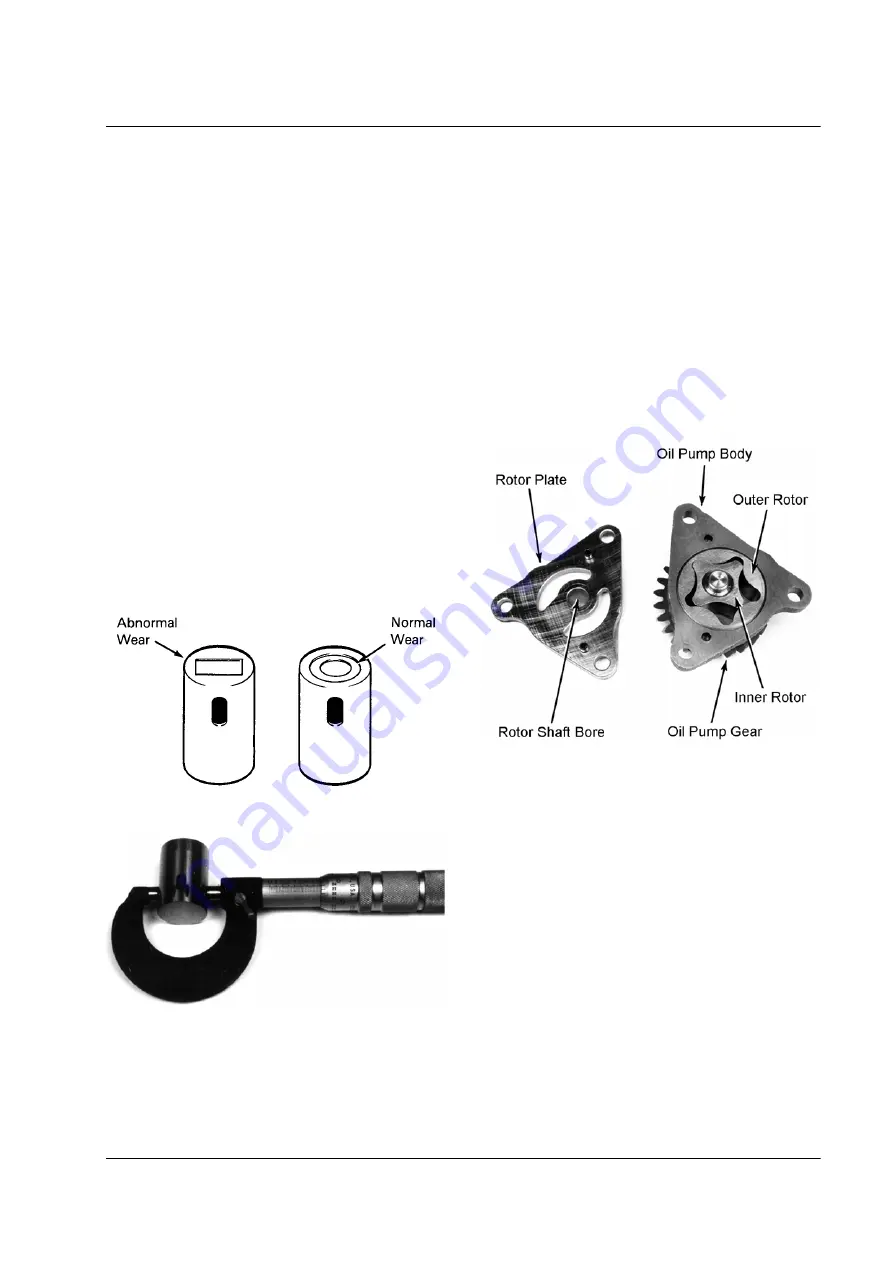

1. Clean and inspect the tappets. Normally the tappets

rotate while the engine is running. This causes normal

wear to appear as concentric rings on the surface of the

tappet that contacts the cam lobe. A tappet that does not

rotate shows an abnormal wear pattern straight across

its contact surface. Replace any tappet that shows an

abnormal wear pattern, significant wear, or significant

damage.

Tappet Wear

Measuring Tappet

aea383

aea278

2. Measure the outside diameter of each tappet. Replace

any tappets that are smaller than the wear limit (refer to

Specifications).

Oil Pump

1. Remove the rotor plate and inspect the oil pump. If the

rotor plate, the inner rotor, the outer rotor, or the oil

pump body show significant wear, scratches, or dam-

age, replace the oil pump.

Oil Pump Assembly

2. Use a feeler gauge to check the clearance between the

oil pump body and the outer rotor. The standard dimen-

sion is .0039 to .0063 in. (0.100 to 0.160 mm). The

wear limit is .0098 in. (0.250 mm). If the clearance

between the oil pump body and the outer rotor is larger

than the wear limit, replace the oil pump.

3. Use a feeler gauge to check the clearance between the

inner rotor and the outer rotor. Place the feeler gauge

between the tip of a vane on the inner rotor and the high

point of a lobe on the outer rotor. If the clearance

between the inner rotor and the outer rotor is more than

.0059 in. (0.150 mm), replace the oil pump.

aea279