Electrical (Rev 1/97)

107

d. Turn the commutator or the core down if they

exceed this limit. Also turn the commutator down

to remove any wear grooves made by the brushes.

e.

Replace the armature if the commutator has an out-

side diameter that is less than 1.142 in. (29.00 mm)

after being turned down.

f.

If the commutator is only dirty, clean it up with

500-600 grit sandpaper.

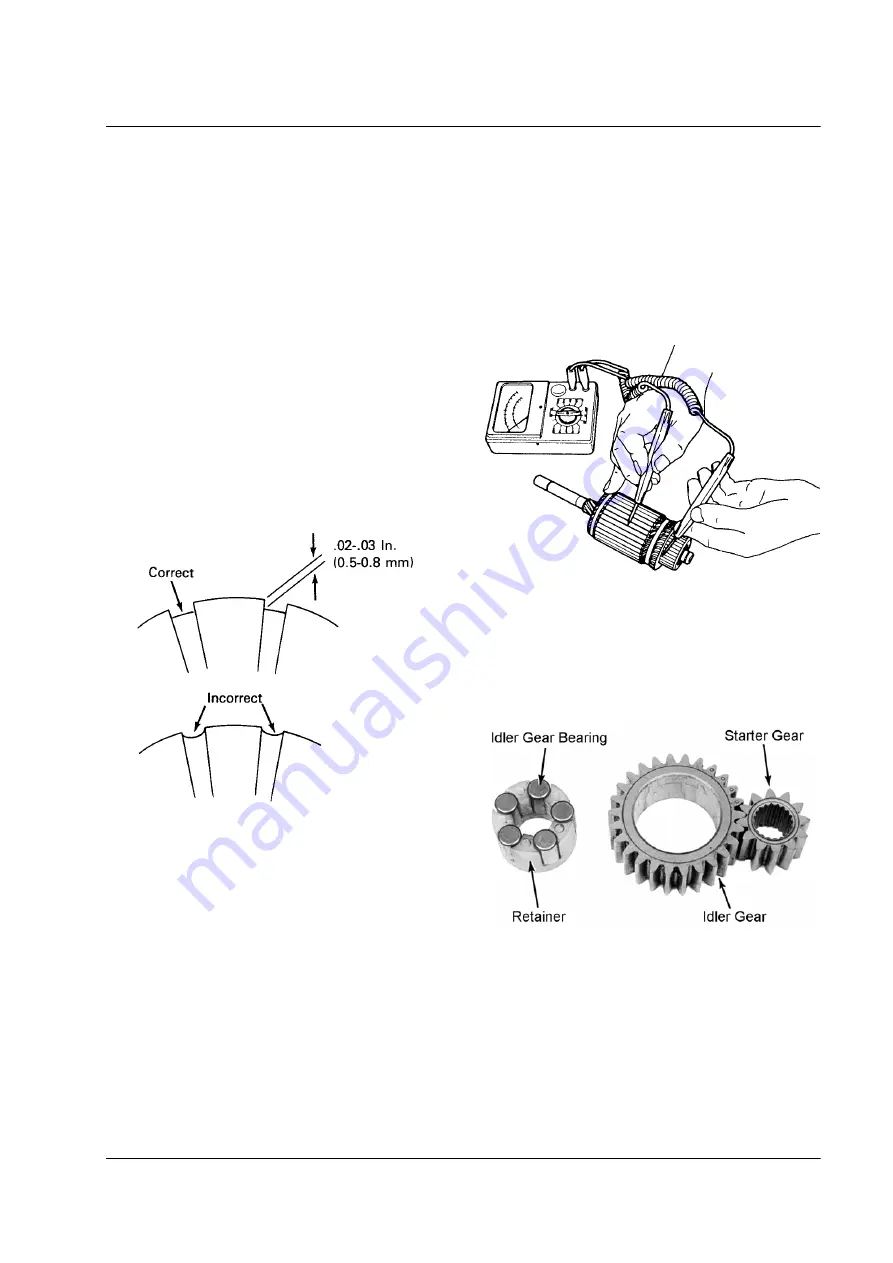

g. After turning down the commutator, check the

undercut of the mica. The standard undercut is .02-

.03 in. (0.5-0.8 mm). Cut the undercut down to the

proper depth if it is less than .02 in. (0.5 mm).

Check Undercut

h. Check the armature coils with a growler and an

ammeter. Place the ammeter leads on each pair of

commutator bars that are directly opposite each

other. The ammeter will show no current in an

open coil and lower than normal current in a

shorted coil. Replace the armature if any of the

coils are defective.

i.

Check the armature insulation with an ohmmeter

set on the RX1000 scale. There should be infinite

aea376

resistance between each commutator bar and the

armature core or shafts. Replace the armature if

there is any continuity between the armature coils

and the core.

Check Armature Insulation

Gears and Bearings

Inspect the starter gear, idler gear, idler gear bearings, and

bearing retainer. Replace any of these parts that show signif-

icant wear or damage.

Inspect Gears and Bearings

Pinion Assembly

1. Inspect each part of the pinion assembly and replace

any part that shows significant wear or damage.

aea377

aea378