81

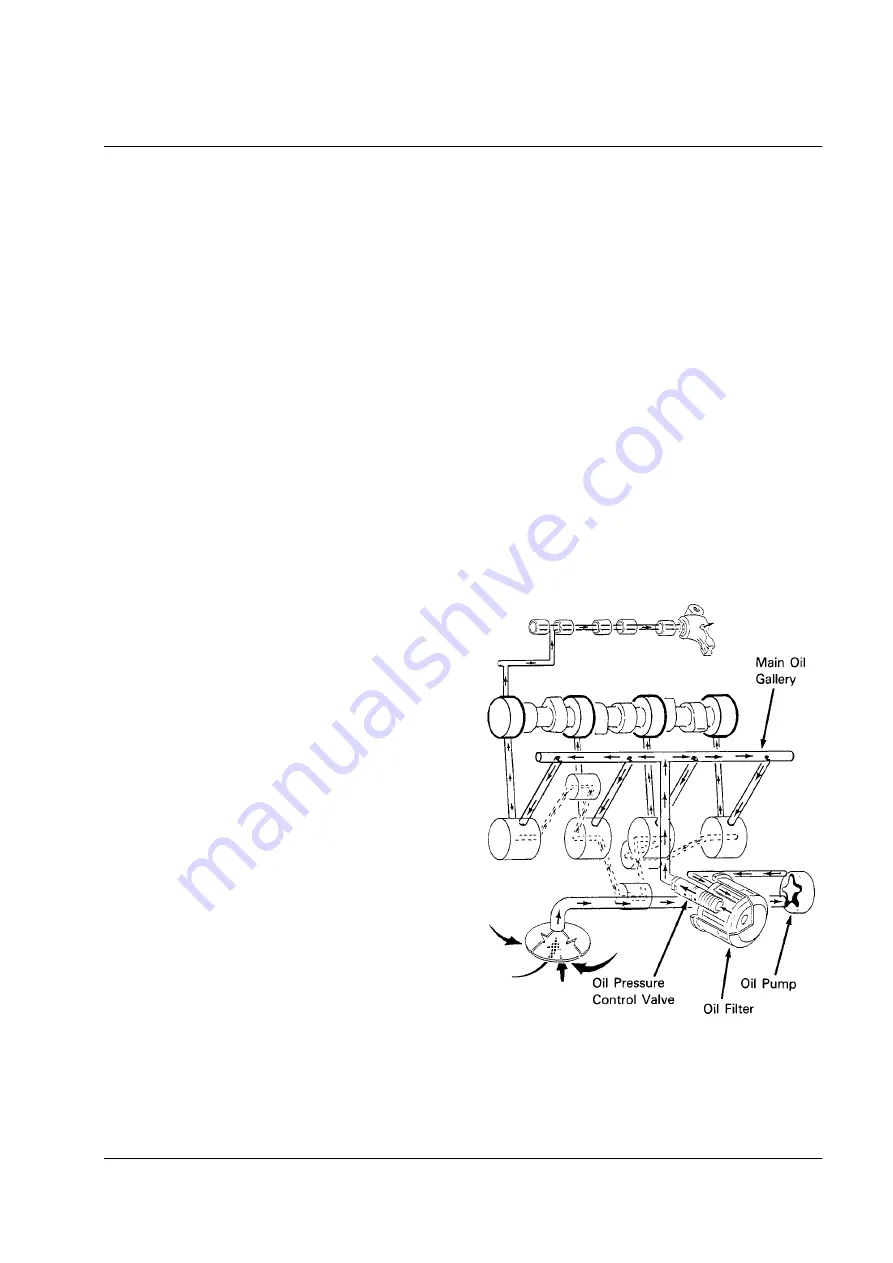

Lubrication System

These engines all use a pressure lubrication system. A tro-

choid type oil pump circulates the oil through the system to

lubricate the engine components. The oil pump is driven by

the crankshaft gear, and is attached to the lower part of the

timing gear housing.

The oil is picked up by a screened inlet near the bottom of

the oil pan. The inlet is positioned far enough from the bot-

tom of the pan to avoid picking up any of the residue that

tends to settle on the bottom of the pan. The oil then passes

through the intake pipe to the oil pump.

The oil pump forces a large volume of high pressure oil

through an oil gallery to the oil filter. Dirt and other parti-

cles are trapped in the filter element as the oil passes

through the oil filter. If the filter element becomes clogged,

a bypass valve built into the oil filter allows the oil to

bypass the filter element. This keeps the engine components

from being starved for oil if the filter element is clogged.

After passing through the oil filter, the oil is still at high

pressure when reaches the oil pressure control valve and the

main oil gallery. The oil pressure control valve limits the oil

pressure in the main oil gallery to approximately 43 psi (294

kPa) by diverting the excess oil back into the oil pan. Oil

passages connected to the main oil gallery supply oil to the

idler gear shaft, the fuel injection pump, and to each main

bearing.

Oil from the idler gear shaft lubricates the idler gear bush-

ing, the idler gear, and the other timing gears before return-

ing to the oil pan.

The oil that flows to the fuel injection pump returns to the

oil pan after lubricating the injection pump components.

Some of the oil supplied to the main bearings flows through

passages in the crankshaft to the connecting rod bearings.

This oil is thrown around the bottom end of the engine as is

flows out of the bearings while the crankshaft rotates. Some

of this oil lubricates the cylinder walls. Some of this oil

lands in the holes on the top of the connecting rods and

lubricates the wrist pins and the connecting rod bushings.

The oil eventually returns to the oil pan.

Some of the oil supplied to the main bearings flows through

passages in the cylinder block to the camshaft bearings.

From here some of the oil flows through passages in the cyl-

inder block, the cylinder head, and the rocker arm supports

to the rocker arm shaft. The rocker arm shaft supplies oil to

the rocker arm bushings and the rocker arms. Some oil

squirts out of holes in the rocker arms to lubricate the valve

stem caps and the valve stems. The oil that is pumped up to

the rocker arm assembly flows back down through the push

rod openings and lubricates the tappets and the cam lobes as

it returns to the oil pan.

Oil pressure is affected by oil temperature, oil viscosity, and

engine speed. Low oil pressure can usually be traced to the

lack of oil, a faulty oil pressure control valve, loose connec-

tions in the lubrication system, or worn bearings. Low oil

pressure is not normally caused by a faulty oil pump.

Lubrication System

aea330