Fuel System (Rev 1/97)

93

Major Component Inspection

NOTE: If a plunger assembly or a plunger guide assembly

is replaced the injection pump must be recalibrated by a

qualified diesel injection service shop.

Plunger and Plunger Barrel

NOTE: Because the clearance between the plunger and

the plunger barrel is only .0004 in. (0.010 mm), these com-

ponents must be replaced if they show any sign of wear or

damage. The plunger and plunger barrel are replaced as a

set.

1. Clean the plungers and carefully inspect them with a

magnifying glass. Replace any plunger that is

scratched, worn, discolored, or has any chips on the

edges of the lead groove.

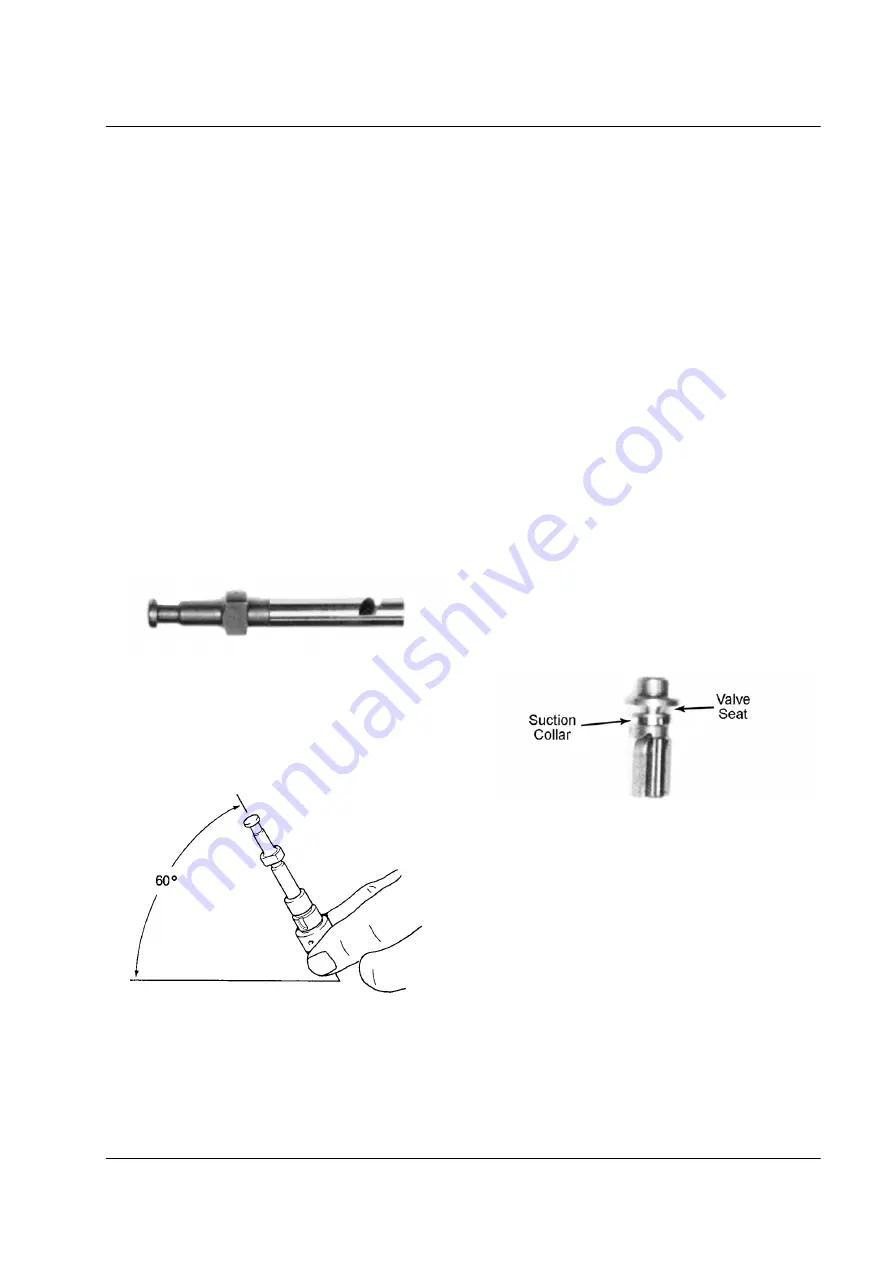

Plunger

2. Test the plunger and the plunger barrel using the fol-

lowing procedure:

a.

Insert a plunger about half way into its respective

plunger barrel while holding them horizontally.

Plunger Test

aea349

aea350

b. Slowly tilt them up to an angle of approximately

60 degrees. The plunger should slide smoothly into

the plunger barrel.

c. Repeat this test several times and turn the plunger

about a quarter of a turn each time.

d. Replace the plunger if it slides into the plunger bar-

rel too easily or if it stops part way in.

Plunger Barrel Seal

The plunger barrel seal keeps the diesel fuel from diluting

the engine oil. Therefore, the plunger barrel seal must be

replaced if it shows any signs of wear or damage.

Delivery Valve

The delivery valve and the delivery valve holder are a set

and must be replaced together.

1. Clean and inspect the delivery valve. Replace the deliv-

ery valve if the suction collar or the seat is scratched,

damaged, or shows any signs of wear.

Delivery Valve

2. Test the suction collar using the following procedure:

a. Hold the delivery holder upright and cover the hole

in the bottom with your finger.

b. Place the delivery valve in the delivery valve

holder and press it into the delivery valve holder.

The delivery valve should spring back a little when

it is released.

aea351