Inspection and Reconditioning (Rev 1/97)

56

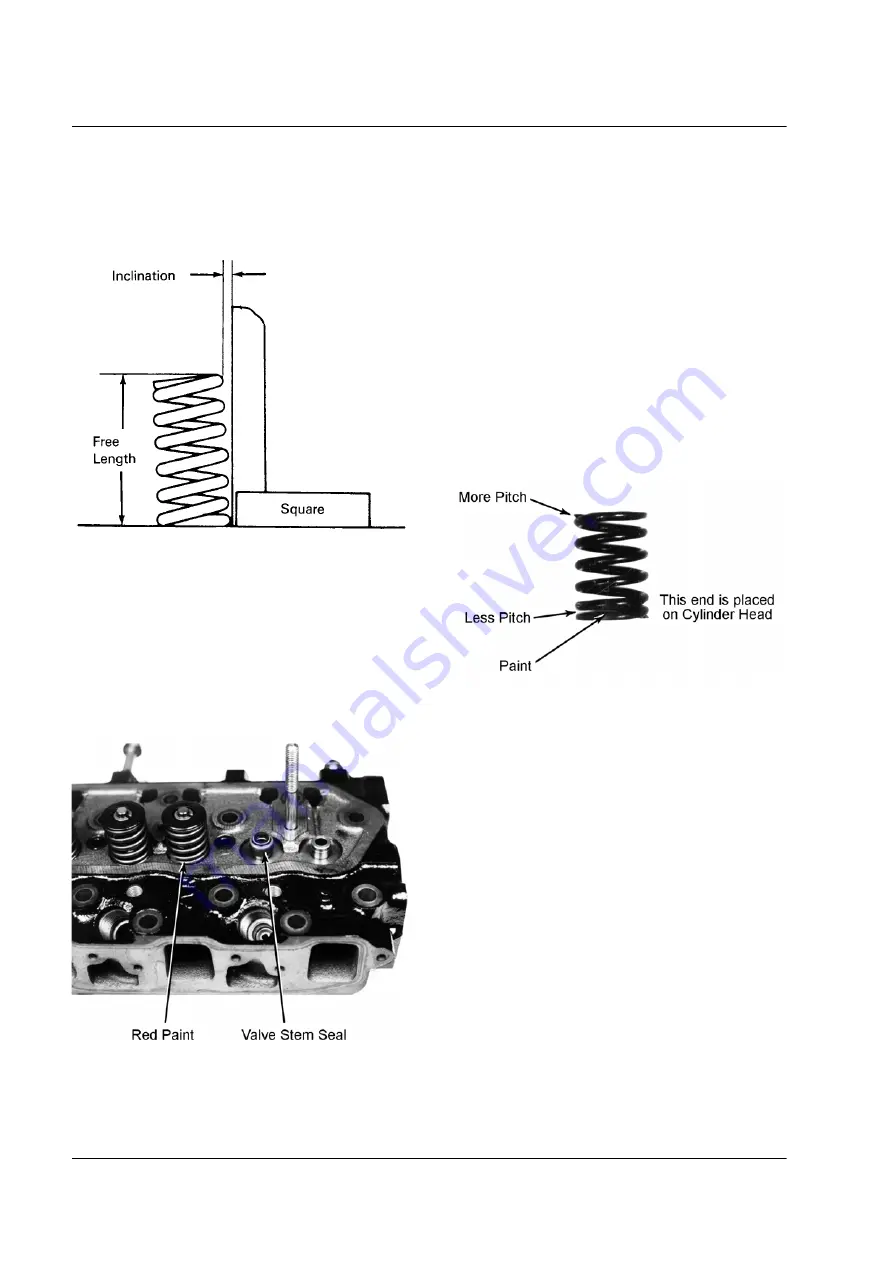

Valve Spring Measurements

4. Inspect the valve stem caps, the valve spring retainers,

and the valve keepers. Replace any of these compo-

nents that show significant wear or damage.

Cylinder Head Assembly

Assemble the cylinder head after all the components have

been reconditioned or replaced. Thoroughly clean the cylin-

der head and all the components before assembly.

Installing Valve Stem Seals

aea269

aea270

1. Lightly oil the valve stem seals and place them on the

valve guides.

NOTE: New valve stem seals should always be used

when assembling the cylinder head.

2. Oil the valve stem and place the valves in their respec-

tive valve seats. Oiling the valve stems prevents them

from seizing to the new valve stem seals.

3. Install the valve springs. The end of a valve spring that

has less pitch (this end is wound tighter and may have

some paint on it) should be placed on the cylinder head.

Valve Spring

4. Place the valve spring retainers in the valve springs and

compress the valve springs with a valve spring com-

pressor.

5. Install the valve keepers and remove the valve spring

compressor.

6. After installing the valves, place the cylinder head on

the intake side and fill the exhaust ports with diesel

fuel. Check to see if any diesel fuel is leaking past the

exhaust valves. Turn the cylinder head over and check

the intake valves in the same way. Minor seeping is

acceptable, but any valves that leak significantly must

be removed and lapped.

a.

To lap a valve place a small amount of medium grit

valve lapping compound on the valve face.

aea271