6-11

DMS-B150L/B210S/B80L/B110S/EX150L/EX210S

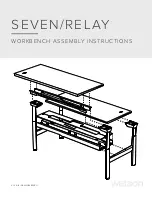

Fixing the Console

(In case of 3 to 6 extension consoles)

1.

Check that height of the point

A

is 110 mm above the

floor.

If height of the point

A

is not 110 mm above the

floor, adjust the height by loosening the four nuts of

the respective casters with hexagon allen wrench

(diagonal size 10 mm) and by adjusting the casters.

(Rotating a caster 360 degrees clockwise raises the

console by 2.5 mm. Rotating a caster 360 degrees

counter-clockwise lowers the console by 2.5 mm.)

2.

Place a level on the portions

B

and

C

, and check that

the basic console is level. If they are not level, adjust

them by adjusting the casters until they are level.

3.

Loosen the four nuts securing the floor levelers.

4.

Rotate the hexagonal bolt block of the floor leveler by

hand until the feet of the console contacts the floor,

and completely ground them on the floor.

n

If the bolt block cannot be rotate by hand, use a spanner.

In addition, be careful not to rotate the bolt block exces-

sively. Otherwise, the console will be raised.

5.

Respectively rotate the four floor levelers by 180

d

with

a spanner.

6.

Fasten the nut.

(Use a spanner of 30 mm across.)

Height from the floor level is 110 mm.

A

B

C

Bubble

The bubble in the level must stay in the

center of the internal gauge lines.

Caster

N20

M20

Allen wrench

(10 mm)

Nut

Floor leveler

Hexagonal bolt

block

6-4. Installation of the Basic Console