Alarm, fault and system messages

12.4 Fault correction

SIPART PS2 with PROFIBUS communication

Operating Instructions, 09/2007, A5E00127926-07

239

12.4.6

Remedial measures table 5

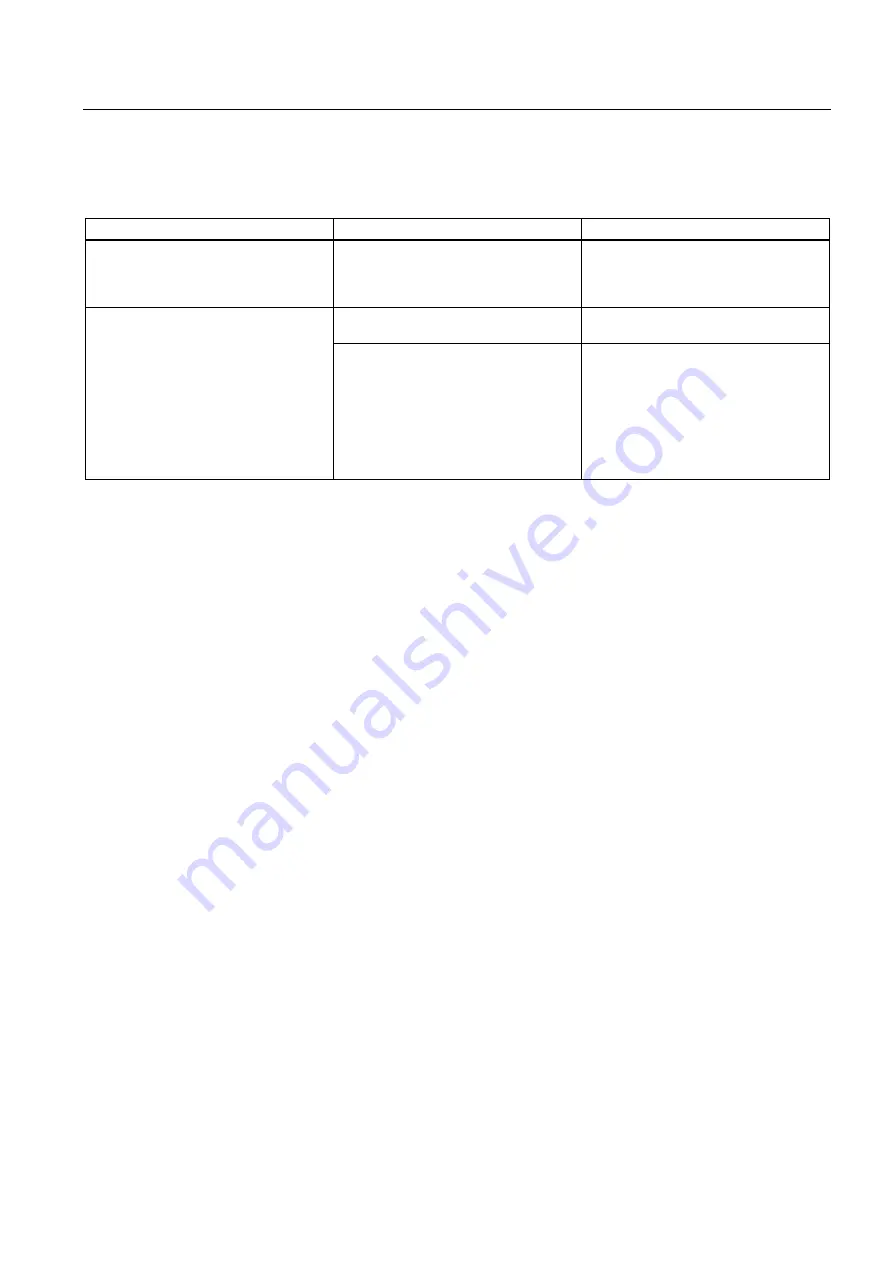

Fault profile (symptoms)

Possible cause(s)

Remedial measures

•

Zero point displaces sporadically

(> 3%).

•

Impact or shock loads result in

accelerations so high that the

friction clutch moves, e.g. due to

"vapor shocks" in vapor lines.

•

Rectify the causes for shock loads.

•

Re-initialize the positioner.

•

Electrical auxiliary power supply is

not adequate.

•

Check the electrical auxiliary power

supply.

•

The device function has completely

failed: no view even on the digital

display.

•

In case of very high continuous

loads due to vibrations

(oscillations):

•

Screws of the electrical connecting

terminals may be loosened.

•

Electrical connecting terminals

and/or electronic components may

be knocked out.

•

Tighten the screws firmly and

secure using sealing wax.

•

Repair

1)

•

For prevention: Install the positioner

on the damping pads.

Fault table 5

1)

More information is given under the also-see link.

Содержание SIPART PS2 PA 6DR55 Series

Страница 2: ......

Страница 270: ...Appendix A 3 Test report SIPART PS2 with PROFIBUS communication 270 Operating Instructions 09 2007 A5E00127926 07 ...

Страница 271: ...Appendix A 3 Test report SIPART PS2 with PROFIBUS communication Operating Instructions 09 2007 A5E00127926 07 271 ...

Страница 272: ...Appendix A 3 Test report SIPART PS2 with PROFIBUS communication 272 Operating Instructions 09 2007 A5E00127926 07 ...

Страница 286: ...Glossary SIPART PS2 with PROFIBUS communication 286 Operating Instructions 09 2007 A5E00127926 07 ...

Страница 290: ...Index SIPART PS2 with PROFIBUS communication 290 Operating Instructions 09 2007 A5E00127926 07 ...

Страница 291: ......