Manual – IPOSplus®

81

6

Modulo function

Position Detection and Positioning

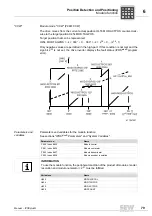

In this example, the following numbers of teeth were ascertained:

Z1 = 17 / Z2 = 74 / Z3 = 8 / Z4 = 33 / Z5 = 16 / Z6 = 93

The following calculations must be performed to determine the SHELL parameters

modulo numerator, modulo denominator and modulo encoder resolution:

The numerator and denominator were reduced in the above example (happens auto-

matically with the Wingear program).

This results in the following input values for the SHELL parameters:

• Modulo numerator = 113553

• Modulo denominator = 1088

• Modulo encoder resolution = 4096

Step 3: Modulo range of representation and maximum target position

Check the modulo range of representation:

The product of the modulo encoder resolution and modulo numerator must be < 2

31

(decimal 2147483648).

Modulo numerator x modulo encoder resolution = 113553 × 4096 = 465113088

=> The condition has been met, the target position can be represented.

Check the maximum target position:

The maximum target position corresponds to 4.6 output revolutions.

477251979

M

N

= Modulo numerator

M

D

= Modulo denominator

i

G

= i gear unit

i

AG

= i additional gear

TP

max

= maximum target position

M = Modulo

M

N

= Modulo numerator

M

ER

= Modulo encoder resolution

M

M

i

i

M

M

Z

Z

Z

Z

Z

Z

M

M

N

D

G

AG

N

D

N

D

=

×

=

+

+

+

+

=

=

2

4

6

1

3

5

227106

2176

113553

1088

TP

M

M

M

N

ER

max

.

=

°

=

×

=

×

=

2

360

2

2

113553 4096

4 6

31

31

31

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n