EN

Page 44 of 77

INSTRUCTION, USE AND

MAINTENANCE MANUAL

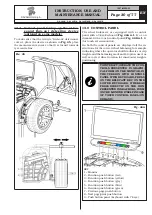

14.6 Use of machines with disabled auto-

matic data gauge

The entry of diameter, width and distance measures

of the machine rim must be performed manually. The

reading of these measures can be made as follows:

- visual readout on caliper graduated scale (distance);

- values readout on rim (diameter and width);

- width value detection with manual caliper (width)

(see

Fig. 61

).

Fig. 61

MANUAL CALIPER.

Width manual detection

14.6.1 Manual setting of wheel dimensions

In case the operator wants to edit and/or manually

enter the wheel dimensions, proceed as follows:

- from the desired measurement mode screen, press

the button

until highlighting with blue the field

to modify/edit;

- press the buttons

or

until reaching the

desired value;

- press button

to shift to the next value.

After entering all the required measures, you can spin

the wheel by pressing the button

and closing

the protective guard.

NOTE: if the distance-diameter caliper is disabled,

the displayed page for detected unbalance is

as follows:

1

2

Fig. 62

In this screen page,in addition to the information of the

detected unbalance, there are measurements in mm

at which you must remove the caliper arm (

Fig. 62

ref.

_

1-2

) to apply the weights inside the rim.

14.7 Standard balancing programs

14.7.1 Static

The STATIC program permits balancing wheels by fit-

ting adhesive weights on the outer and inner sides of

the rim. Enter the measurements (see Par. 14.2.1 or

14.6.1) and proceed as described in Par. 14.5.

At the end of the procedure, the wheel balancing condi-

tions can be checked by performing a trial spin.

The procedure has now been completed.

RAVAGLIOLI S.p.A.

1297-M005-03

G4.140R - G4.140WS - G4.140WSLB - GP4.140WS