44

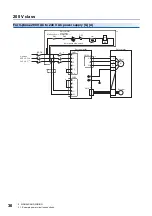

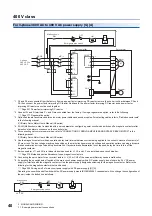

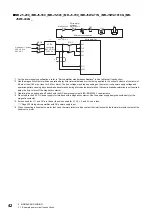

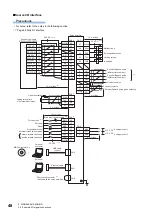

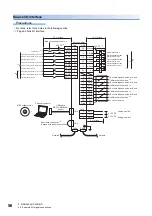

3 SIGNALS AND WIRING

3.2 Example I/O signal connections

*1 To prevent an electric shock, connect the protective earth (PE) terminal (the terminal marked with the

symbol) of the servo amplifier

to the protective earth (PE) of the cabinet.

*2 Connect the diode in the correct direction. If it is connected reversely, the servo amplifier may malfunction and not output signals,

disabling protective circuits such as EM2 (Forced stop 2).

*3 If the controller does not have the forced stop function, install a forced stop 2 switch (normally closed contact).

*4 When starting operation, turn on EM2 (Forced stop 2), LSP (Forward rotation stroke end), and LSN (Reverse rotation stroke end)

(normally closed contact). If FLS (Upper stroke limit) and RLS (Lower stroke limit) are used via a controller, wiring LSP and LSN is

unnecessary. In that case, set [Pr. PD41].

*5 Use SW1DNC-MRC2-_.

*6 The devices of these pins can be changed with servo parameters ([Pr. PD03] to [Pr. PD05]).

*7 To prevent an unexpected restart of the servo amplifier, configure a circuit that turns off EM2 when the main circuit power supply is

turned off.

*8 If not using the STO function, attach the short-circuit connector that came with the servo amplifier.

*9 Supply 24 V DC ± 10 % to interfaces from outside. The total current capacity of these power supplies is 300 mA maximum. The

amperage will not exceed 300 mA when all I/O signals are used. Reducing the number of I/O points decreases the current capacity. For

the amperage required for interfaces, refer to the following.

Page 96 Digital input interface DI-1

Although the diagram shows the input signal and the output signal each using a separate 24 V DC power supply for illustrative purposes,

the system can be configured to use a single 24 V DC power supply.

*10 If no alarm is occurring, ALM (Malfunction) is on (normally closed contact).

*11 The pins with the same signal name are connected in the servo amplifier.

*12 The devices of these pins can be changed with servo parameters ([Pr. PD07] to [Pr. PD09]).

*13 If installing an external brake mechanism for a linear servo motor or direct drive motor, use MBR (Electromagnetic brake interlock).

*14 For source interfaces, the positive and negative outputs of the power supply are reversed as compared with sink interfaces.

*15 This signal can be used only on the MR-J5-_G_-RJ_.

*16 If using the MR-J5-_G_-RJ_, this device can be changed to TPR3 (touch probe 3) by servo parameter settings. To set the device to

TPR3, the wiring must be the same as TPR1 and TPR2.

Содержание MELSERVO-J5 MR-J5-G Series

Страница 1: ...MR J5 User s Manual Hardware MR J5 _G_ MR J5W_ _G_ MR J5 _A_ Mitsubishi Electric AC Servo System ...

Страница 2: ......

Страница 473: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 471 12 MEMO ...

Страница 477: ......