-65-

Practice 3: Specifying the force command value and the damping coefficient

PStart

Use the damping coefficient when the robot vibrates even the gain or force command value is

adjusted in any method.

Understand the effect of the damping coefficient through this practice.

Key learning points

In this practice, the robot is vibrated on purpose to understand the effect of the

damping coefficient.

Normally, the damping coefficient is used when the robot does not stop vibrating

even the gain is adjusted.

Caution

1) Execute program "3" to check the movement.

2) Create program "3" with RT ToolBox3 and write it to the robot.

3) When the writing is completed, close the program.

Open the program again, and check that the 8th line is "M_FsCod0=0" (tool coordinate system).

4) Operate the robot by the JOG operation and move it to the PStart position.

(* Teach the scale plate center position over the contact position again.)

5) Turn OFF the enable switch of the T/B, switch to "Automatic" with the mode selection switch,

and lower OVRD to 10%. Then execute the automatic operation.

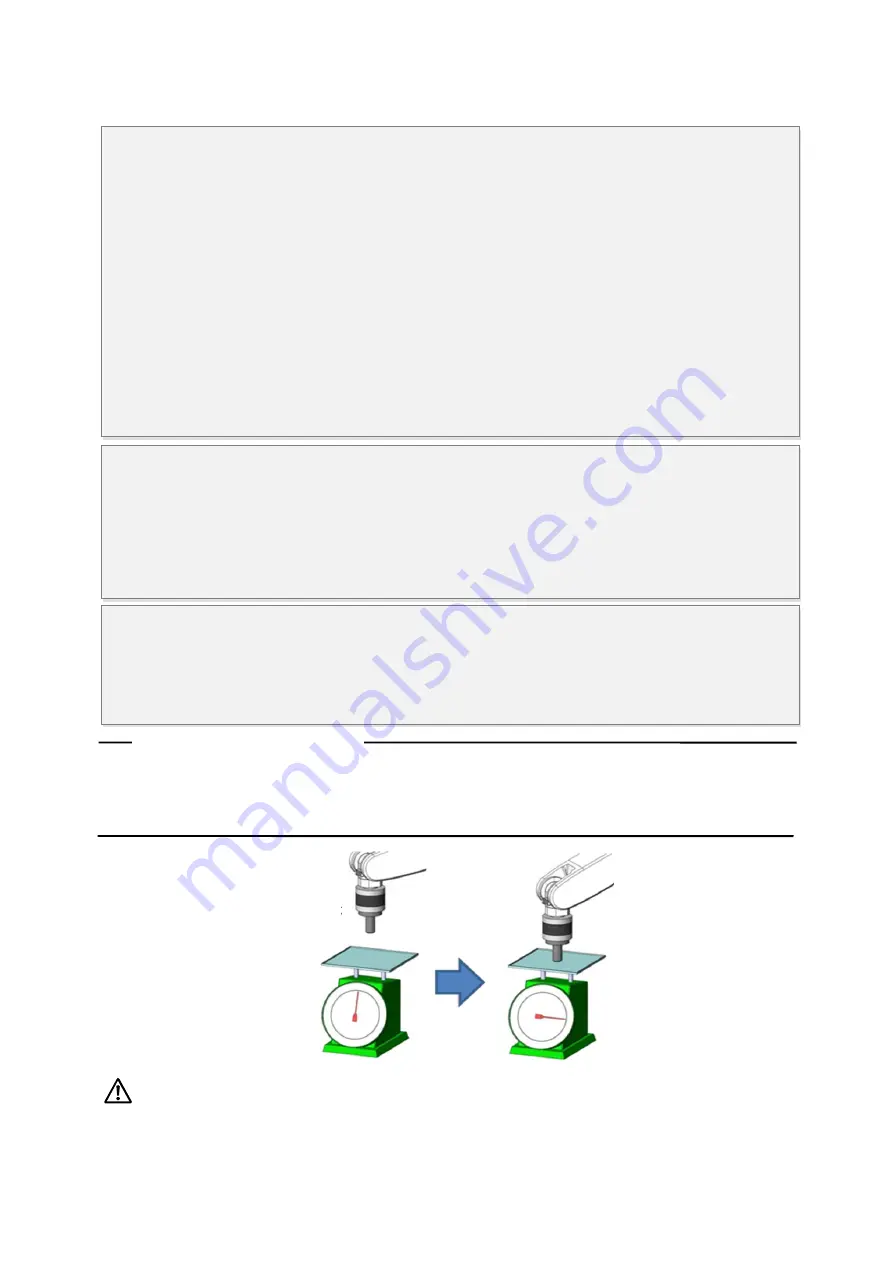

6) The robot stops for 10 seconds when the scale points at approximately 0.5 kg. Wait for the

robot moving above and the servo turning OFF

。

9) Input "0.05" to the Z-axis component in the 6th line P_FsDmp0 =

(+0.00,+0.00,+0.00,+0.00,+0.00,+0.00) in the program. Then execute the automatic

operation again.

10) Check that the scale pointer settles at 0.5 kg.

7) Open program "3", and adjust P_FsFCd0 = (+0.00,+0.00,+5.00,+0.00,+0.00,+0.00) in the 10th

line, and change the Z-axis gain from "5" to between "40" and "50". Then execute the

automatic operation again.

8) Check that the needle of the scale points at 0.5 kg unstably.

(If it is stable, adjust the gain within the range in which an error occurs.)

Содержание MELFA BFP-A3614

Страница 1: ...Mitsubishi Industrial Robot Robot Seminar Textbook Force Sensor Application BFP A3614 ...

Страница 2: ......

Страница 8: ... Revision History Print Date Instruction Manual No Revision content 2018 07 31 BFP A3614 First print ...

Страница 33: ... 22 b CR800 R controller CN1 connector CR800 R controller front To OPT1 connector CPU module SSCNET III cable ...

Страница 34: ... 23 2 F series a CR750 D controller ...

Страница 35: ... 24 b CR751 D controller ...

Страница 36: ... 25 c CR750 Q CR751 Q controller CPU module ...

Страница 75: ... 64 MEMO Please use this page for your memo ...

Страница 95: ... 84 MEMO Please use this page for your memo ...

Страница 103: ... 92 MEMO Please use this page for your memo ...

Страница 111: ... 100 MEMO Please use this page for your memo ...

Страница 119: ... 108 MEMO Please use this page for your memo ...

Страница 123: ... 112 MEMO Please use this page for your memo ...

Страница 129: ... 118 MEMO Please use this page for your memo ...

Страница 133: ... 122 MEMO Please use this page for your memo ...

Страница 137: ... 126 MEMO Please use this page for your memo ...

Страница 143: ... 132 MEMO Please use this page for your memo ...

Страница 149: ... 138 MEMO Please use this page for your memo ...

Страница 153: ... 142 MEMO Please use this page for your memo ...

Страница 159: ... 148 MEMO Please use this page for your memo ...

Страница 171: ... 160 MEMO Please use this page for your memo ...

Страница 183: ... 172 MEMO Please use this page for your memo ...

Страница 191: ... 180 MEMO Please use this page for your memo ...

Страница 211: ......