14

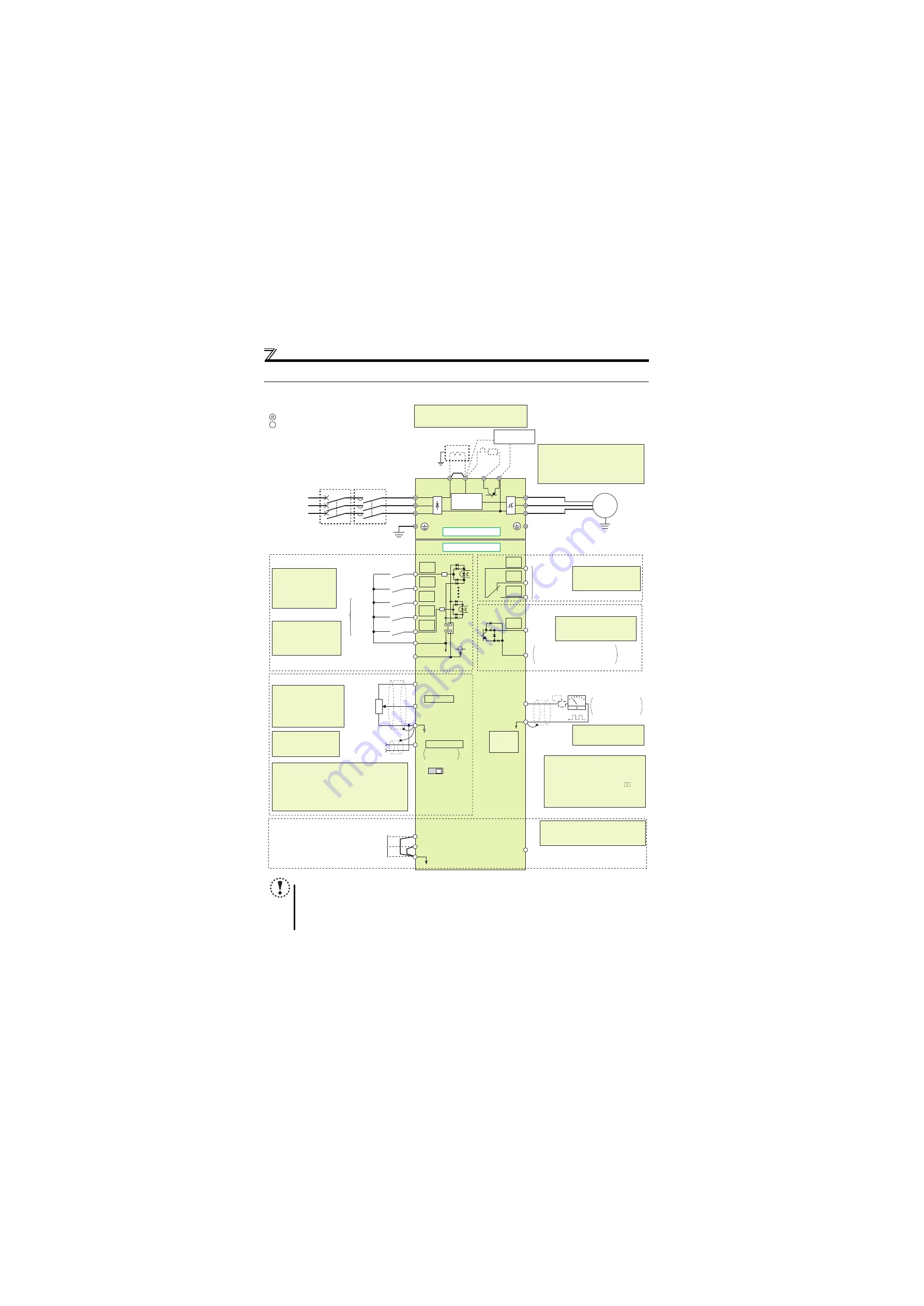

Wiring

2.1 Wiring

2.1.1

Terminal connection diagram

NOTE

To prevent a malfunction caused by noise, separate the signal cables more than 10cm from the power cables. Also

separate the main circuit wire of the input side and the output side.

After wiring, wire offcuts must not be left in the drive unit.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the drive unit clean. When drilling mounting

holes in an enclosure etc., take caution not to allow chips and other foreign matter to enter the drive unit.

Earth

(Ground)

Motor

M

Earth (Ground)

Three-phase

AC power

supply

MCCB

MC

R/L1

P1

P/+

PR N/-

S/L2

T/L3

U

V

W

Earth

(Ground)

*6 Brake resistor (FR-ABR, MRS type, MYS

type)

Install a thermal relay to prevent an

overheat and burnout of the brake resistor.

(The brake resistor cannot be connected

to the 0.2K.)

*7 It is not necessary when

calibrating the indicator

from the operation panel.

Forward

rotation start

Reverse

rotation start

Middle

speed

High

speed

Low

speed

Control input signals (No voltage input allowed)

24VDC power supply

(Common for external power supply transistor)

Contact input common

STR

STF

RH

RM

RL

SD

PC

Relay output

Running

Open collector output

Open collector output common

Sink/source common

RUN

SE

A

B

C

Speed setting signals (Analog)

2 0 to 5VDC

10(+5V)

2

3

1

4 4 to 20mADC

Speed

setting

potentiometer

1/2W1k

Ω

Terminal 4

input

(Current

input)

(+)

(-)

5(Analog common)

*4 It is recommended to

use 2W1k

Ω

when the

speed setting signal is

changed frequently.

*4

*2 When using terminals

PC-SD as a 24VDC

power supply, take care

not to short across

terminals PC and SD.

PU

connector

*

1. DC reactor (FR-HEL)

When connecting a DC reactor, remove the

jumper across P1 and P/+

Control circuit terminal

Main circuit terminal

Sink logic

Jumper

*1

*6

*2

*3

*5

*8

Multi-speed selection

Terminal functions vary by

Pr. 190 RUN terminal function

selection

Terminal functions vary

by

Pr. 192

A,B,C terminal

function selection

SINK

SOURCE

V

I

*5

0 to 5VDC

(0 to 10VDC)

0 to 10VDC

*5 Terminal input specifications can be changed by analog

input specifications switchover (

Pr. 267

). Set the

voltage/current input switch in the "

V

" position to select

voltage input (0 to 5V/0 to10V) and "

I

" (initial value) to

select current input (4 to 20mA).

To use terminal 4 (initial setting is current input), set "4"

in any of

Pr. 178 to Pr. 182 (input terminal function

selection)

to assign the function, and turn ON AU signal.

Voltage/current

input switch

Main circuit

Control circuit

R

Relay output

(Fault output)

Brake unit

(Option)

FM

SD

Indicator

(Speed meter, etc.)

+

-

Moving-coil type

1mA full-scale

Calibration resistor

*7

*3 Terminal input specifications

can be changed by analog

input specifications

switchover (

Pr. 73

).

Terminal 10 and terminal 2

are used as PTC input

terminal (

Pr. 561

).

S1

S2

SC

SO

For manufacturer *9

For manufacturer *9

*9 The terminals S1, S2, SC, and SO are for

manufacturer setting. Do not remove the

shortening wires across the terminals S1

and SC and the terminals S2 and SC.

Inrush current

limit circuit

24V

The function of these

terminals can be

changed to the reset

signal, etc. with the input

terminal assignment

(

Pr. 178 to Pr. 182

).

*8 Operation and parameter setting can be

done from the parameter unit

(FR-PU07) and the enclosure surface

operation panel (FR-PA07).

(Use the option cable (FR-CB2 ).)

RS-485 communication can be utilized

from a personal computer and other

devices.

Содержание FR-D720-0.2K-G

Страница 45: ...34 MEMO ...

Страница 293: ...290 MEMO ...

Страница 294: ...291 APPENDIX This chapter provides the APPENDIX of this product Always read the instructions before using the equipment ...