SECTION 5

TROUBLESHOOTING

106

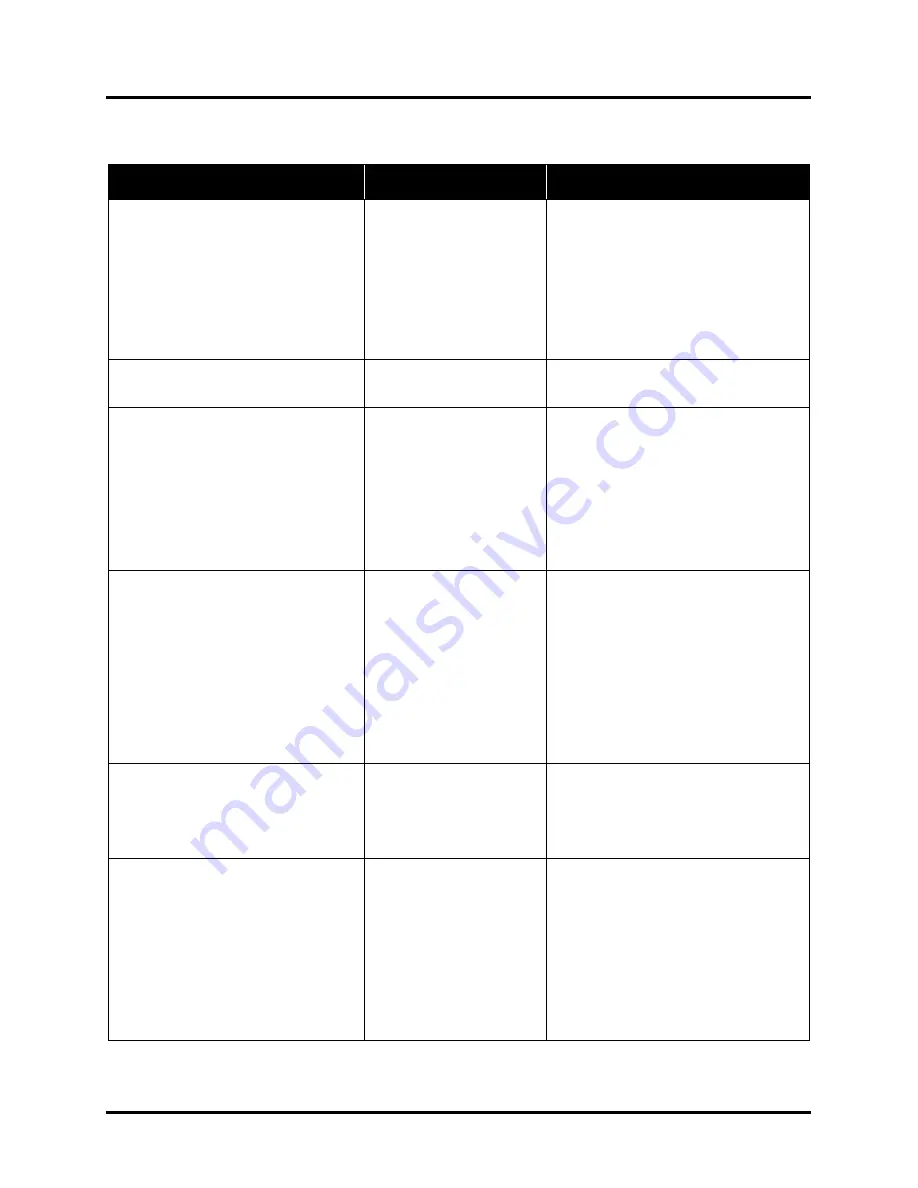

Toolbox System Status Messages

(continued)

SYSTEM STATUS

SOURCE

SOLUTION

System Status:

MECH_FAIL_PERMANENT

ERROR

on

System Status

screen.

Check the

Printer Graphic

to

determine what component has a

problem or failed:

Ink Valve

,

Printhead

, etc., (usually indicated with

a steady

“?”

)

Mechanical error

One of Printer's

mechanical components

was not properly registered

at expected position.

Mechanical failure or

Sensor failure.

Visually inspect component stated as a

“Reason” for failure.

Using

Scan Sensors

page in the Printer

Toolbox

, perform toggle test on Sensor

responsible for registration of failed

mechanical component position.

Try rebooting (

restarting

) printer.

If problem persists call for Service.

System Status:

ONLINE

Printer Ready

System is ready to accept jobs and print.

System Status:

PAPERPATH_FEED_TIMEOUT

Out of Paper

Hesitation in media feed.

Media Thickness set too

high.

Media not passing under

Feeder/Entry Sensors.

Load media into Printer and tap

Clear

Error

and then tap

Resume

button, from

Job Menu, to resume printing.

If media is present; check/adjust Media

Thickness, Guides and Separators.

Reposition media or Feeder/Entry

Sensor Assembly, so paper passes

under sensors.

System Status:

PAPERPATH_PAPERJAM

Paper/Media jam detected.

Printer has detected that

one (

or more

) Media

Sensors are blocked

(

interrupted

).

Carefully remove jammed media from

Printer and close Print Engine. System

Status message in

red

should go away.

Touchscreen and Toolbox

Paperpath

Sensor indicators

should change from

red to green.

After jam is cleared, you can:

Check/adjust sheet separation.

Tap

Clear Error

and then tap

Resume

button, from Job Menu, to resume

printing.

System Status:

PAPERPATH_EXIT_SENSOR

Exit Sensor does not see

media.

Media not passing over

Exit Sensor or Underside

of media is dark in color.

Check/clean Exit Sensor

Reposition media so paper passes over

Exit sensor or select “Ignore Exit Sensor”

from “Media Setup” menu.

System Status:

PAPERPATH_PAGE_SEQUENCE

Change in media length

detected.

Shinny media surface or

hole in media.

Hesitation or skew in

media feed.

Overlapping pieces.

Remove media from the Printer

transport. Check/adjust sheet

separation.

Reposition media or Feeder/Entry

Sensor Assembly, so paper passes

under sensors. Avoid windows or holes

in media.

Turn off “Double Feed Detection”

Tap

Clear Error

and then tap

Resume

button, from Job Menu, to resume

printing.

Содержание Quadient Rena MACH 6

Страница 1: ...Digital Color Inkjet Printer MACH 6 User Guide...

Страница 131: ......

Страница 132: ...2 1 2020 Quadient April 9 2020...