SECTION 5

TROUBLESHOOTING

101

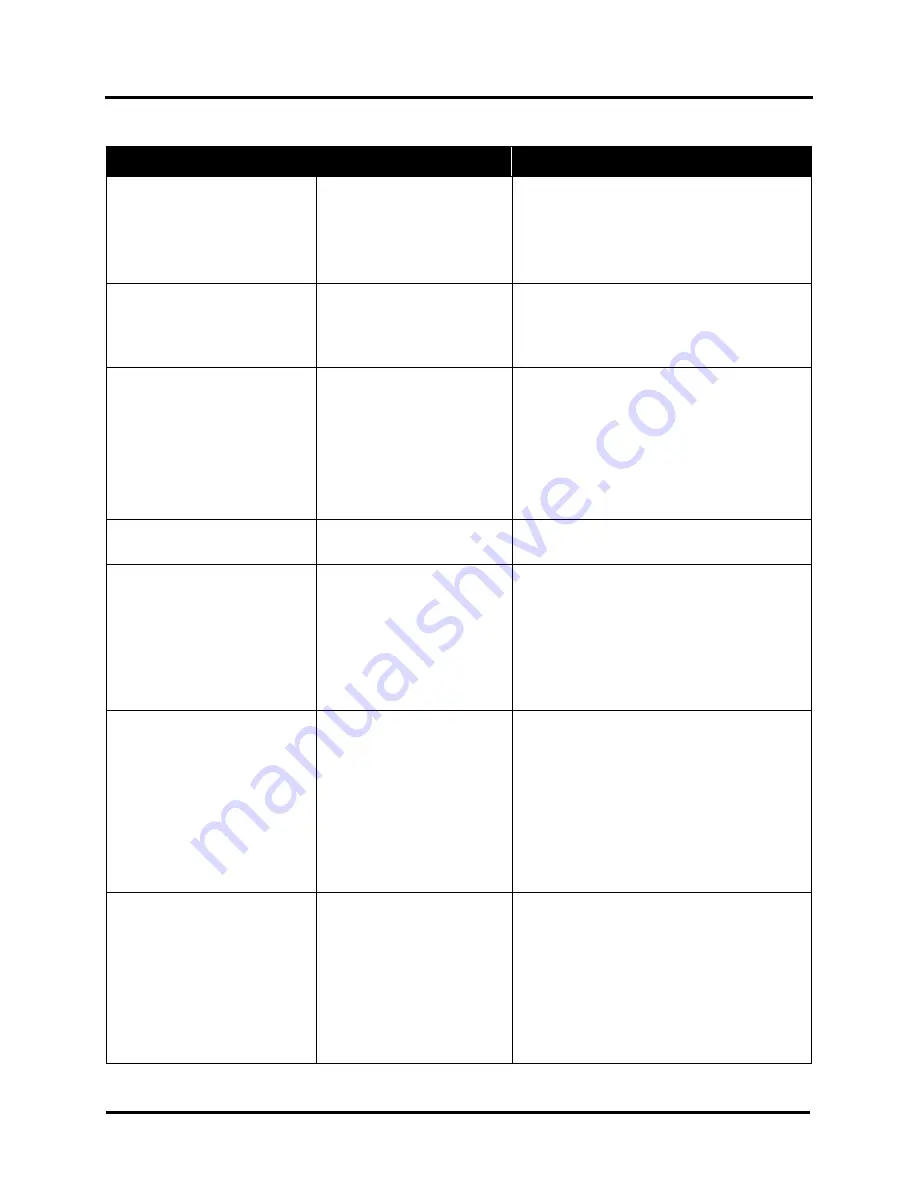

Printer (continued)

CONDITION

PROBLEM / CAUSE

SOLUTION

Intermittent missing dots

(lines, in direction of media

travel)

or changes in color,

that temporarily improve after

Mid-Job Servicing (MJS)

occurs.

Automatic Printhead

Maintenance features need

to be adjusted.

Set “

Mid-Job Servicing

” to a lower value.

Set “

KWS

” to a higher level.

Set “

Interpage Frequency

” to lower value.

Persistent missing dots

(crisp or jagged lines, in

direction of media travel)

Clogged or dirty Printhead.

Air in printhead/ink lines

Clean Printhead using “

Maintenance

”

features. Run “

Full Clean Printhead

”.

Replace Printhead and Wiper Roller.

Blurry/wavy images

Printhead too far from media

surface.

Printhead needs

maintenance or replacement.

Reduce Media Thickness and or Print Height

values to bring Printhead closer to media.

Clean Printhead using Maintenance features

(

Quick/Normal/Full Clean

) from Printer

Touchscreen or Toolbox.

Clean Printhead manually using distilled water

and a wet, clean, lint-free cloth.

Replace Printhead and Wiper Roller.

Black bar/line printed near

trailing edge of media

Purge Bar hitting trailing edge

of media.

Check/adjust “

Purge Bar Position

”.

Feeding problems and or

image distortions

Double sheets. Misfeeds.

Media hesitating or skewing.

Adjust Sheet Separators.

Check adjust Media Thickness.

Try using low (3 dot) Print Platen.

Verify that Print Platen & Drip Tray Assembly

are installed properly; sitting level.

Try unlocking, but not opening, the Exit

Transport Cover.

Image smudging or offset

occurring

Wet image/media making

contact with something that is

causing image to smudge.

Wet image traveling under

exit rollers is being picked up

by rollers, causing part of

image to be repeated in

direction of media travel.

Increase Print Height value to move Printhead

farther from media surface.

Try unlocking, but not opening, the Exit

Transport Cover.

If “Over Speed” is selected, Turn it OFF.

Reduce Print Quality.

If using “Normal” print quality, try selecting

“Half Speed”.

Use inkjet suitable media.

Print position shifting in

direction of media travel and

or not printing on some

pieces.

Printer not able to

consistently detect lead edge

of media.

Media hesitating after it

reaches the Media Sensor.

Media being delivered too

fast for system to get next

image ready to print.

Reposition Feeder/Entry Sensor Assembly, so

paper passes under sensors. Avoid windows

or holes in media. Some media surfaces are

very reflective and may not be compatible.

Check/adjust Media Thickness.

If “Over Speed” is selected, Turn it OFF.

If using “Normal” print quality, try selecting

“Half Speed”.

Содержание Quadient Rena MACH 6

Страница 1: ...Digital Color Inkjet Printer MACH 6 User Guide...

Страница 131: ......

Страница 132: ...2 1 2020 Quadient April 9 2020...