OPERATING CONTROLS AND PROCEDURES

CD25

3-14

Published 1-06-2017 Control # 579-01

Swing Drive and Turntable Bearing

Warm-up Procedures for Temperatures Above -7°C

(20°F):

1.

Setup the crane on fully extended outriggers, with the

boom fully retracted and near maximum lift angle with no

load applied.

2.

Rotate the superstructure at a speed of less than one

RPM for at least one complete revolution in one

direction, then rotate the superstructure at a speed of

less than one RPM for at least one complete revolution

in the opposite direction.

Warm-up Procedures for Temperatures Below -7°C

(20°F):

1.

Ensure the boom is fully retracted and near maximum lift

angle with no load applied.

2.

Rotate the superstructure at a speed of less than one-

half RPM for at least two complete revolutions in one

direction, then rotate the superstructure at a speed of

less than one-half RPM for at least two complete

revolutions in the opposite direction.

Axles

Warm-up Procedures for Temperatures Below -35°C

(-30°F):

1.

Setup the crane on outriggers.

2.

Engage the transmission and allow crane to run at idle

until the temperature of the transmission sump reaches

normal operating temperature.

Hydraulic Oil System

Operating Limits and Warm-up Procedures:

•

From 4°C to -10°C (40°F to 15°F):

Crane operation

without a load is allowed with medium engine RPM and

medium function speed (joystick position) until the fluid

reaches at least 10°C (50°F). It is then recommended

that all crane functions be cycled to remove cold fluid

from all components and cylinders of the hydraulic

system. If there is any unusual sound coming from the

crane’s hydraulic pumps or motors, stop the operation

and engine immediately and contact a Manitowoc

distributor.

•

From 10°C to 4°C (50°F to 40°F):

Crane operation with

a load is allowed with medium engine RPM and medium

function speed (joystick position) until the fluid reaches

at least 10°C (50°F).

•

From 95°C to 10°C (200°F to 50°F):

Crane operation

with a load is allowed with no restrictions.

•

Above 95°C (200°F):

No crane operation is allowed. Let

the crane’s hydraulic oil cool by running the engine at

idle with no functions actuated.

Cab Heater Warm-up

An Intermediate Speed Control (ISC) function of the Engine

Control Unit (ECU) is programmed to raise the idle speed to

1200 RPM when it gets a signal from the machine electrical

system. This may occur when the crane sets at idle without

operating the crane functions for extended periods of time.

Three conditions are required in order to provide this signal:

•

The engine coolant temperature is less than 71° C

(160° F).

•

The transmission is in neutral.

•

The Crane Function Switch is in the off position.

If any of these conditions change, the signal is lost, the ISC

function is turned off, and the idle returns to 800 RPM.

NOTE:

The brake must be applied in order to engage

transmission.

Starting the Engine

Normal Engine Starting

NOTE:

Never leave the engine running while the crane is

unattended. Shut off the engine to prevent

unauthorized persons from operating the controls.

Walk around the crane and warn all personnel who

may be servicing the crane or are in the crane’s

path prior to starting. Do not start until all personnel

are clearly away from the crane.

1.

Enter the cab and adjust the operator’s seat for

comfortable operation.

2.

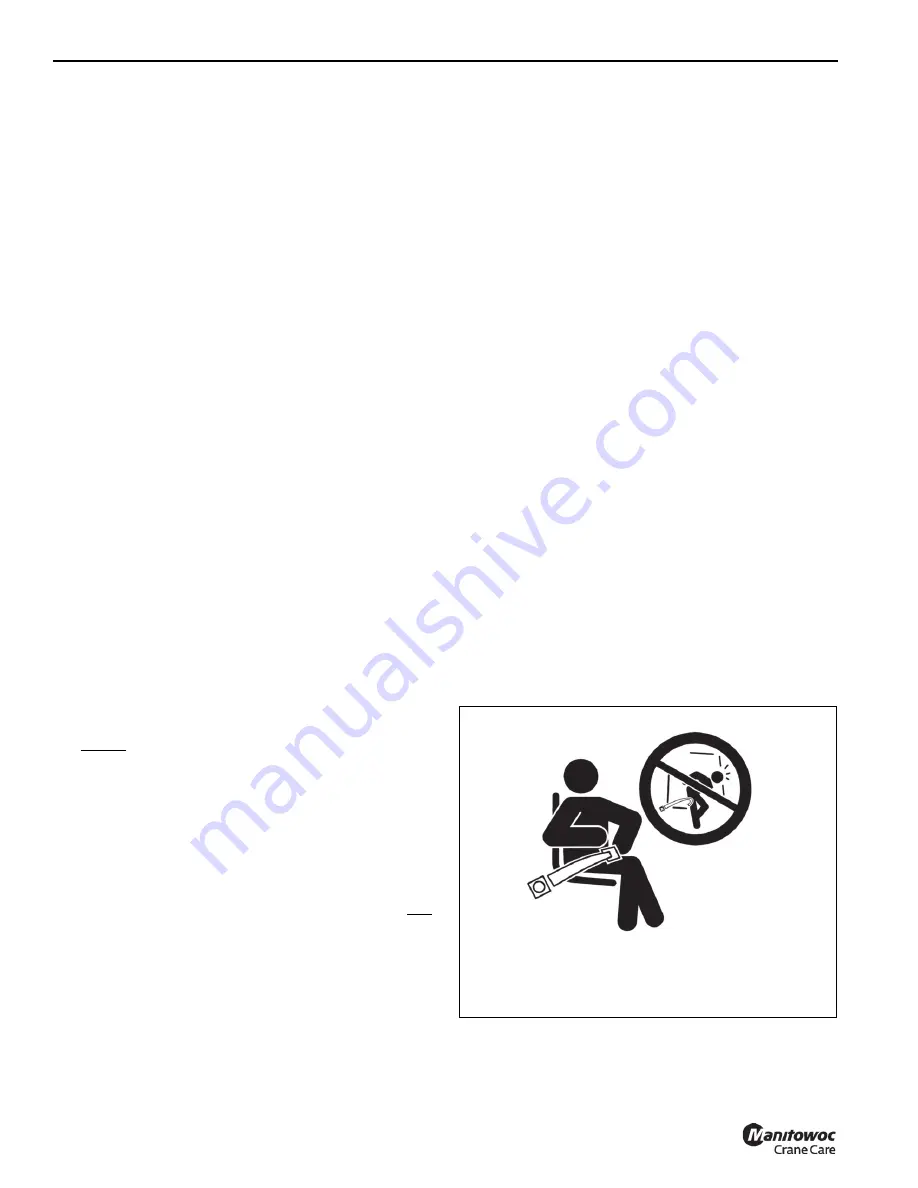

Fasten the seat belt.

3.

Check that the parking brake (Figure 3-21) is engaged,

press the top of the switch.

w0003

The operator’s seat is equipped with a seat belt. Use

this belt at all times when operating the crane.

Reference Only

Содержание CD25

Страница 5: ...Operator Manual CD25 R e f e r e n c e O n l y ...

Страница 6: ...R e f e r e n c e O n l y ...

Страница 14: ...TABLE OF CONTENTS CD25 OPERATOR MANUAL TOC 6 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 18: ...INTRODUCTION CD25 1 4 Published 1 06 2017 Control 579 01 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 55: ...2 37 CD25 SAFETY INFORMATION 2 Published 1 06 2017 Control 579 01 8496 1 FIGURE 2 10 R e f e r e n c e O n l y ...

Страница 66: ...SAFETY INFORMATION CD25 2 48 Published 1 06 2017 Control 579 01 2 48 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 100: ...CAPACITY CHART CD25 4 4 Published 1 06 2017 Control 579 01 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 150: ...MAINTENANCE CD25 6 40 Published 1 06 2017 Control 579 01 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 152: ...ADJUSTMENTS CD25 7 2 Published 1 06 2017 Control 579 01 THIS PAGE BLANK R e f e r e n c e O n l y ...

Страница 156: ...8 4 SPECIFICATIONS CD25 Published 1 06 2017 Control 579 01 Boom angle Maximum 80 Minimum 0 R e f e r e n c e O n l y ...

Страница 159: ...R e f e r e n c e O n l y ...

Страница 160: ...R e f e r e n c e O n l y ...