© 2015 Sensata Technologies

Installation

16

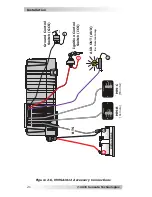

BATTERY

DC cable

with ring lug

bolt

flat washer

nut

lock washer

battery

post

battery terminal

Temperature sensor

(BTS)

Verify that the

DC cable lugs are flush

with the battery terminals.

Torque the battery terminals

from 10 to 12 ft-lbs.

Figure 2-4, DC Cable to Battery Terminals

2.3.5 Battery Bank Wiring

WARNING:

Lethal currents will be present if the positive

and negative cables attached to the battery bank touch each

other. During the installation and wiring process, ensure the

cable ends are insulated or covered to prevent touching/

shorting the cables.

Info:

DO NOT connect the DC wires from the battery bank

to the inverter until: 1) all DC wiring complete, 2) the correct

DC and AC overcurrent protection have been installed, and

3) the correct DC voltage and polarity have been veri

fi

ed.

Info:

For optimum performance, a minimum battery bank

of 200 AH is recommended.

Depending upon the type of batteries you use in the installation

(6 or 12 VDC), the batteries must be wired in series, parallel, or series-

parallel to provide 12 VDC (see Appendix B – Battery Information,

for guidance on wiring batteries together). The interconnecting DC

wires must be sized and rated exactly the same as those that are

used between the battery bank and the inverter.

Place the batteries as close as practical to the inverter, preferably in

an insulated and ventilated enclosure. Allow adequate space above

the batteries to access the terminals and vent caps (as applicable).

Allow

≥

1” (2.5 cm) of space between the batteries to provide good

air

fl

ow. DO NOT mount the batteries directly under the inverter.

Info:

To ensure the best performance from your inverter

system do not use old or untested batteries. Batteries

should be of the same size, type, rating, and age.