40

DESCRIPTION

The

THIN

boiler has been designed for outdoor installation in partially protected areas and can operate at

winter temperatures as low as –15

°

C. It is largely intended for installation on balconies and terraces. This unit

is practically “invisible” as it is designed to be wall-mounted just 80 mm above the floor.

The boiler is equipped with an anti-freeze system designed to protect the heating and domestic hot water

circuits; when necessary, this ignites the burner until the set minimum water temperature is restored. To cover

all eventualities, an electrical element kit, to be fitted on the domestic hot water circuit, is also available.

This unit has passed all the tests required by strict European Community safety standards.

The boiler has IP44 protection rating, is fully automatic with continuous flame modulation and ionisation

ignition; it is C-type and can be installed as a sealed chamber or fan-forced draught unit.

All ignition, shut-down, adjustment, programming, display and self-diagnosis functions are effected by a

master

remote control unit.

97

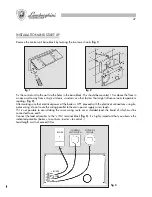

KIT ANTICONGELANTE (A PETICIÓN)

La caldera THIN tiene de serie un dispositivo anticongelante que protege el circuito hidráulico. Tal dispositivo entra en

funcionamiento cuando la temperatura se acerca al valor de 6

°

C. Como ulterior protección del circuito sanitario, se puede

instalar en el sitio, un KIT ANTICONGELANTE que entra en funcionamiento a una temperatura de 4

°

C.

Composición KIT ANTICONGELANTE

1

Resistencia adhesiva 72 x 42 - 230V - 12W

2

Resistencia adhesiva 200 x 53 - 230V - 30W

3

Termostato anticongelante 4

°

C - 14

°

C

4

Capuchón aislante de silicona

5

Vaina aislante Ø 16 interno x 70 mm.

6

Aislador pasapanel

7

Tornillos autorroscantes

8

Aro barril

9

Tric cables resistencia

10

Cambiador rápido

11

Cuadro eléctrico

12

Entrada agua fría

13

Salida agua caliente

14

Entrada sanitario

INSTALACIÓN RESISTENCIAS

Aplicar las resistencias

1

y

2

respetando el sentido indicado en

la figura. Fijar el termostato

3

utilizando los tornillos

7

en la

base presente en el tubo de entrada sanitario y conectar los

faston presentes. Introducir los cables eléctricos en el cuadro

eléctrico teniendo el cuidado de colocar correctamente el aislador

pasapanel

6

en dotación. Conectarlos a los bornes FA1 y FA2

como ilustra la figura (detalle

B

)

Detalle A

Detalle B

Содержание thin 24 MCS W TOP U/IT

Страница 3: ......

Страница 5: ......

Страница 7: ......

Страница 9: ......

Страница 11: ......

Страница 13: ......

Страница 15: ......

Страница 17: ......

Страница 19: ......

Страница 21: ......

Страница 23: ......

Страница 25: ......

Страница 27: ......

Страница 29: ......

Страница 31: ......

Страница 33: ......

Страница 35: ......

Страница 37: ......

Страница 39: ......

Страница 41: ......

Страница 43: ......

Страница 45: ......

Страница 47: ......