49

●

“HOT WATER/HEATING” MODE (

AND

SYMBOLS DISPLAYED)

This mode provides both hot water and heating, operated automatically according to requirements.

●

“HEATING” FUNCTION (

SYMBOL DISPLAYED)

This mode enables the boiler for activation of the heating circuit in “Automatic” or “Manual”.

When this mode is selected you can adjust heating water temperature and set the on/off times to be used

in automatic mode.

In this mode, any request for the production of hot water will be ignored.

“AUTOMATIC” TEMPERATURE CONTROL MODE

The control unit has a daily/weekly timer that automatically adjusts room temperature to “comfort” or “low

temperature” values over a 24 hour period, with independent settings for each of the seven days.

To enable automatic operation press the

key and the

symbol will be displayed.

Hourly programming of temperature values is only permitted with the Heating or Hot water/Heating functions

enabled.

●

HOURLY PROGRAMMING OF TEMPERATURE VALUES

Press key

V

to select the desired day on the

indicators.

The display will then show the programme graph for the selected day by displaying the “indicator lights”

next to the “comfort” level.

To modify these settings press

P

within 5 seconds.

The time “00:00” will now appear on the display and the indicator light corresponding to that time will

begin to flash.

Press the

+

and

–

keys to increase or decrease the time in 30-minute steps.

The

and

symbols show the present value of the indicator light (

comfort temperature

level and

low temperature level)

Select the desired value by acting on the

(comfort temperature level) and

(low tempera-

ture level) keys. The indicator light will take on the desired value and programming will advance by one

step: the next indicator light to be programmed will then flash.

Once programming is over press

P

to memorise settings or

V

to cancel the modifications.

The timer can memorise up to 48 daily temperature value changes.

88

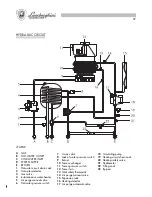

CIRCUITO HIDRÁULICO

DESCRIPCIÓN

A

GAS

B

SALIDA AGUA CALIENTE SA-

NITARIA

C

ENTRADA AGUA FRÍA

D

IDA INSTALACIÓN

E

RETORNO

1

Grifo de vaciado circ. sanita-

rio

2

Sonda circ. sanitario

3

Válvula gas

4

Acumulador instantáneo

5

Purgador manual del aire

6

Presóstato circ. sanitario

7

Válvula 3 vías

8

Presóstato falta de agua

9

Quemador

10

Intercambiador humos

11

Presóstato humos

12

Ventilador humos

13

Termostato de seguridad total

14

Purgador manual del aire

15

Vaso de expansión

16

Sonda circ. calefacción

17

Purgador automático del aire

18

Circulador

19

Grifo de vaciado circ.

calefacción

20

Válvula de seguridad circ.

calefacción

21

Hidrómetro

22

Grifo de llenado

23

By-Pass

Содержание thin 24 MCS W TOP U/IT

Страница 3: ......

Страница 5: ......

Страница 7: ......

Страница 9: ......

Страница 11: ......

Страница 13: ......

Страница 15: ......

Страница 17: ......

Страница 19: ......

Страница 21: ......

Страница 23: ......

Страница 25: ......

Страница 27: ......

Страница 29: ......

Страница 31: ......

Страница 33: ......

Страница 35: ......

Страница 37: ......

Страница 39: ......

Страница 41: ......

Страница 43: ......

Страница 45: ......

Страница 47: ......