2-17

johNSoN coNtroLS

ForM 102.20-N1 (1109)

2

Assembly of indoor unit

See rigging suggestions and details

in Section 1. Failure to follow these

guidelines may result in damage to

equipment.

Do not damage factory installed pipe

chase, electrical cabinet, hoods, pipe

stubs, door handles or roof over-

hang.

See “Ship loose Parts” to identify

gaskets and hardware items.

If the unit or unit sections are too

large to fit through an opening, contact

the local Johnson Controls office for

assistance. Technical instruction is

available for Disassembly and Reas-

sembly.

Installing Multiple Piece Indoor Unit

See Fig. 2-15 and 2-16 for Shipping Split Examples.

If applicable, remove metal tab screwed

to the cross channel and wood ship-

ping blocks before assembling ship-

ping splits.

If assembly is done prior to placing

unit sections, be sure to have sections

on a flat surface during the assembly

process.

1. Before placing sections:

a) Verify the correct sections and orientation of

each section.

b) Remove cross brace(s) (shipping supports)

from each section’s shipping split.

c) Remove plastic shipping covers and their

supports.

d) Make sure all wiring and/or control tubing

connection pig tails are secured out of the

path of the shipping split mating surfaces to

prevent damage.

e) Apply 1/4" x 2" neoprene gasket material

TO ONE SIDE ONly

of each shipping

split. Be sure the entire perimeter is covered

with gasket material, including the foamed

corners. Any void, depression or protrusion

will allow air or water leakage. Gasket must

be continuous through the corners. Make any

splices on a straight run.

Refer to Fig. 2-21

and 2-22.

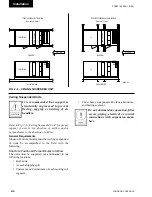

Fig. 2-21 – APPlYing gASKEt tO ShiPPing

SPlit

Fig. 2-22 – APPlYing gASKEt tO dOOR FRAME

WhEn At ShiPPing SPlit

f) For expanded cabinet with end channel

shipping split see fig. 2-23

ld13780A

connectors out of

the way.

panel

Flange

Door Frame

Flange

1/4” x 3/4”

gasket only

used when a

door frame is at

a shipping split.

LD13779

Содержание YORK SOLUTION LD09624

Страница 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...3 27 johnson controls FORM 102 20 N1 1109 3 FIG 3 28 AIR handler start up checklist FORM 100 00 CL1 ...