johNSoN coNtroLS

2-18

ForM 102.20-N1 (1109)

installation

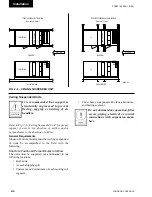

Fig. 2-24 – REMOVE And REPOSitiOn ShiPPing

SPlit AnglE

SECURE TOGETHER USING 3/8" X 3/4"

BOLT, LOCK WASHER & HEX NUT.

REMOVE SHIPPING

BRACKETS

HEAT WHEEL (ER) SEGMENT

END SPLIT MOUNTING BRACKET

FIG. 2-23 – ASSEMBLY OF END CHANNEL SHIPPING SPLIT (EXPANDED CABINET)

LD14262

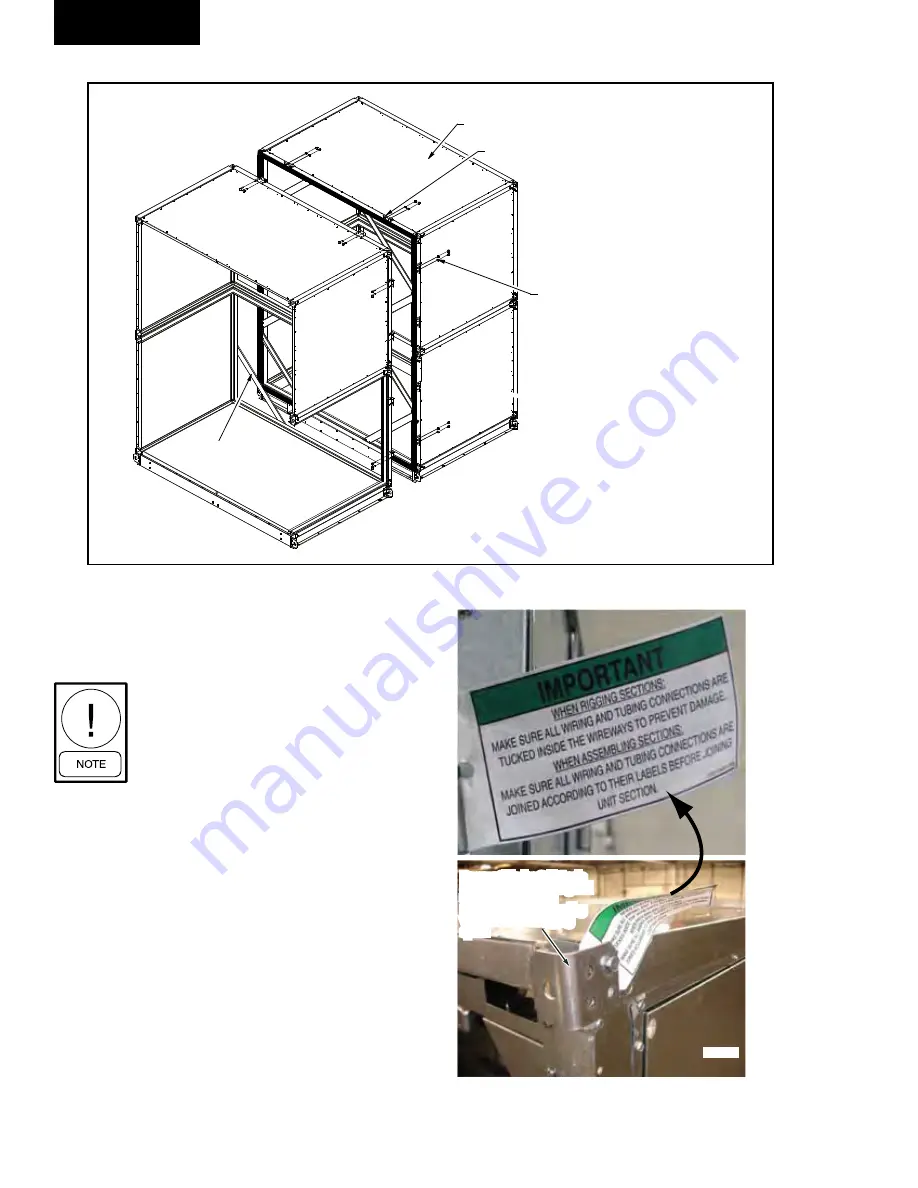

2. Place the first section in its final position and

anchor or block it before placing the next section

(

see Fig. 2-25).

After wiring connections are made

and before proceeding with assembly,

the top shipping split angle will need

to be removed and repositioned (see

Fig. 2-24).

Remove Shipping Split Angle

after completion of wiring and

tubing placement and

reposition before proceeding

with assembly of shipping

splits.

Remove Shipping Split Angle

after completion of wiring and

tubing placement and

reposition before proceeding

with assembly of shipping

splits.

LD14097

Содержание YORK SOLUTION LD09624

Страница 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...3 27 johnson controls FORM 102 20 N1 1109 3 FIG 3 28 AIR handler start up checklist FORM 100 00 CL1 ...