3-3

johNSoN coNtroLS

ForM 102.20-N1 (1109)

3

PRE StARt uP FAn ASSEMBlY inSPECtiOn

When the unit is removed from long-

term storage moisture laden bearing

grease should be purged and replen-

ished with fresh grease per lubrication

decal. The motor should be meggered

to verify that the resistance is still at

a satisfactory level compared to the

value recorded prior to storage.

1. Check the bearings and locking collars

(refer to

Table 3-1, “Torque for Tightening Setscrews”).

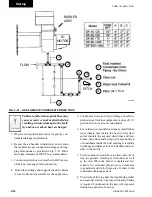

tABlE 3-1 – tORQuE FOR tightEning

SEtSCREWS

SEtSCREW

diA.

HEX. SIZE

ACROSS

FlAtS

Min. RECOMMEndEd

tORQuE

inCh lBS.

FOOt lBS.

1/4

1/8

66 - 85

5.5 - 7.08

5/16

5/32

126 - 164

10.5 - 13.7

3/8

3/16

228 - 296

19.0 - 24.7

7/16

7/32

348 - 452

29.0 - 35.7

1/2

1/4

504 - 655

42.0 - 54.6

5/8

5/16

1104 - 1435

92.0 - 119.6

2. Verify fan wheel properly aligned, tight on shaft

and freely moving.

3. Ensure fan bearings properly lubricated (

see Fan

label or IOM Section 4, “Fan Bearing Lubrica-

tion

”).

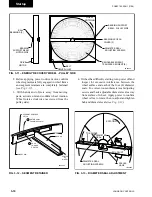

4. Belts and Sheaves

a) Verify

sheaves properly aligned and tight on

shaft. Improper sheave alignment and belt

tension are potential causes of excessive noise

and vibration, as well as shortened belt and

bearing life (

see IOM Section 4, “Sheaves

Alignment

”).

b) Check belt tension. If not familiar with the

process

(see IOM Section 4, “Belts” and

“Adjustable Motor Base Operation”).

It is normal for belts to loosen after start up.

The new belts will “run in” or “take a set” by

seating slightly deeper into the grooves of the

sheaves. Recheck tension after one day and

three days.

c) Ensure motor mounting bolts and adjustable

motor base bolts are tight.

5. Verify tie down bolts removed from 4 corners of

fan base assembly.

In small units the tie down bolts may

only be applied to three corners of

the fan base since one corner is not

accessible.

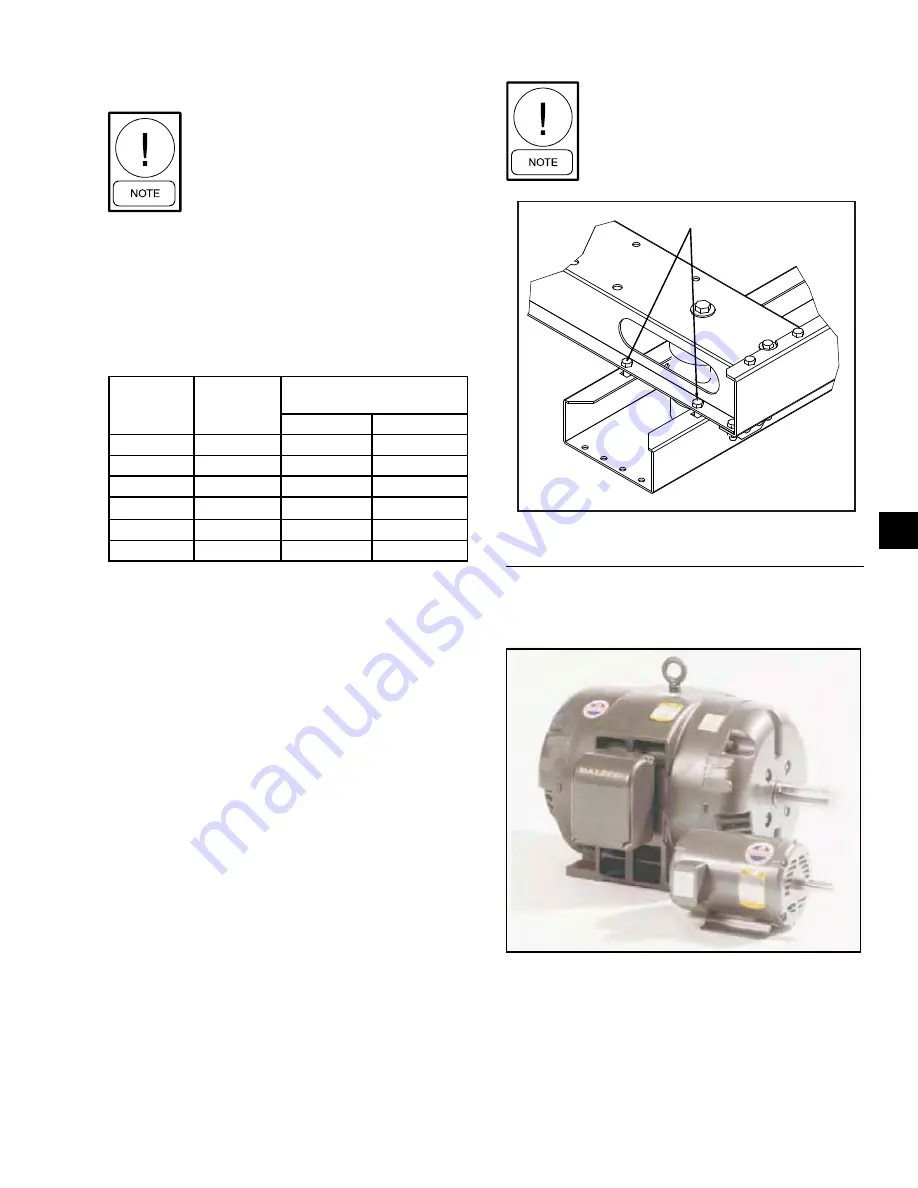

Motors - OdP vs. tEFC

See Fig. 3-3 for ODP.

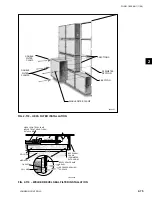

Fig. 3-2 – FAn And MOtOR iSOlAtOR SuPPORt

FRAME.

TIE DOWN BOLTS

LDO9638

Fig. 3-3 – OdP (OPEn dRiP PROOF)

LD09635

Содержание YORK SOLUTION LD09624

Страница 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...3 27 johnson controls FORM 102 20 N1 1109 3 FIG 3 28 AIR handler start up checklist FORM 100 00 CL1 ...