2-23

johNSoN coNtroLS

ForM 102.20-N1 (1109)

2

A

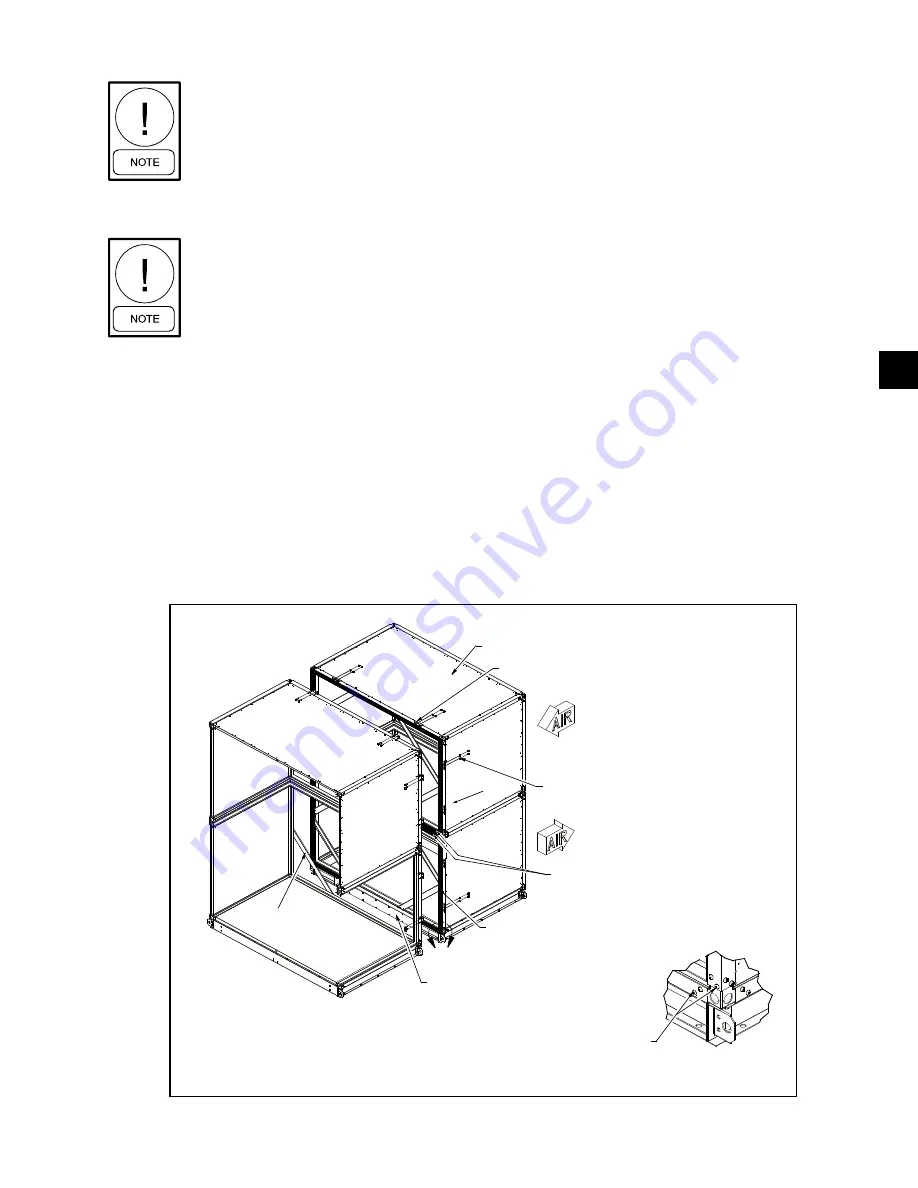

3/16" ALLEN HEAD SCREWS IN RACEWAY

CORNERS AT ENDS OF ALL SEGMENTS

JOINING TOGETHER; MUST BE REMOVED

PRIOR TO PULLING SECTIONS TOGETHER.

REMOVE BASERAIL SUPPORT PLATE

PRIOR TO SECURING LARGE UNITS

TOGETHER.

APPLY 1/4" x 2" NEOPRENE GASKET TO

ALL RACEWAY MATING SURFACES OF

ONE MATING SEGMENT.

SECURE TOGETHER USING 3/8" X 3/4"

BOLT, LOCK WASHER & HEX NUT.

REMOVE SHIPPING

BRACKETS

DETAIL A

HEAT WHEEL (ER) SEGMENT

END SPLIT MOUNTING BRACKET

INCLUDE 2 GASKETS SIDE BY

SIDE ON INTERMEDIATE

RACEWAY SURFACES.

Fig. 2-33 – ASSEMBlY OF End ChAnnEl ShiPPing SPlit

LD12357

See “Ship loose Parts” to identify

gaskets and hardware items.

Assembly of End Channel Shipping Split

The assembly is the same regardless of

what sections are being connected to-

gether. The vertical Energy Recovery

Wheel shown in Fig. 2-33 is a common

example

Prior to pulling sections together:

1. Remove baserail support plate (large units).

2. Remove shipping brackets in corners.

3. Remove screws in raceway corners at ends of all

segments joining together

(as shown in Detail A

of Fig. 2-33).

4. Clean the metal surface where gasket is to be

applied with mineral spirits or rubbing alcohol.

5. Apply 1/4" x 2" neoprene gasket to all raceway

mating surfaces of one mating section. Include

two gaskets side by side on intermediate raceway

surfaces (large units).

6. Ensure that the sections are not racked and will

line up properly.

Attach sections as follows:

1. Make sure assembly surface is clean and level

to allow the sections to slide freely. If surface

is irregular, use metal shims under sections as

necessary to align mating surfaces.

2. Pull sections together using a come along, draw

-

ing the base together.

3. Attach the sides of the sections. Beginning at the

bottom of the sections secure the end channel as-

sembly brackets together using 3/8" x 3/4" Allen

head bolts, lock washers hex nuts at each bracket

. Continue securing the end channel assembly

brackets together, working from bottom to top,

pulling the sections tight.

4. After the sides are secured, secure the brackets on

top of the unit with the same hardware mentioned

in step 3.

(EnERgY RECOVERY WhEEl ShOWn)

Содержание YORK SOLUTION LD09624

Страница 4: ...johnson controls 4 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 10: ...johnson controls 10 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 16: ...johnson controls 16 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 30: ...johnson controls 1 8 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 106: ...johnson controls 2 76 FORM 102 20 N1 1109 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 133: ...3 27 johnson controls FORM 102 20 N1 1109 3 FIG 3 28 AIR handler start up checklist FORM 100 00 CL1 ...