PRODUCTS CONFORMING TO RoHS DIRECTIVE

i

UHL-43 2005 VER1 (E)

PRODUCTS CONFORMING TO RoHS DIRECTIVE

Following products described in this manual are products conforming to RoHS directive.

- UHL-43

Multi purpose Camera

MAINTENANCE OF PRODUCTS CONFORMING TO RoHS DIRECTIVE

Work with care about followings for maintenance of products conforming to RoHS directive.

1. Identification

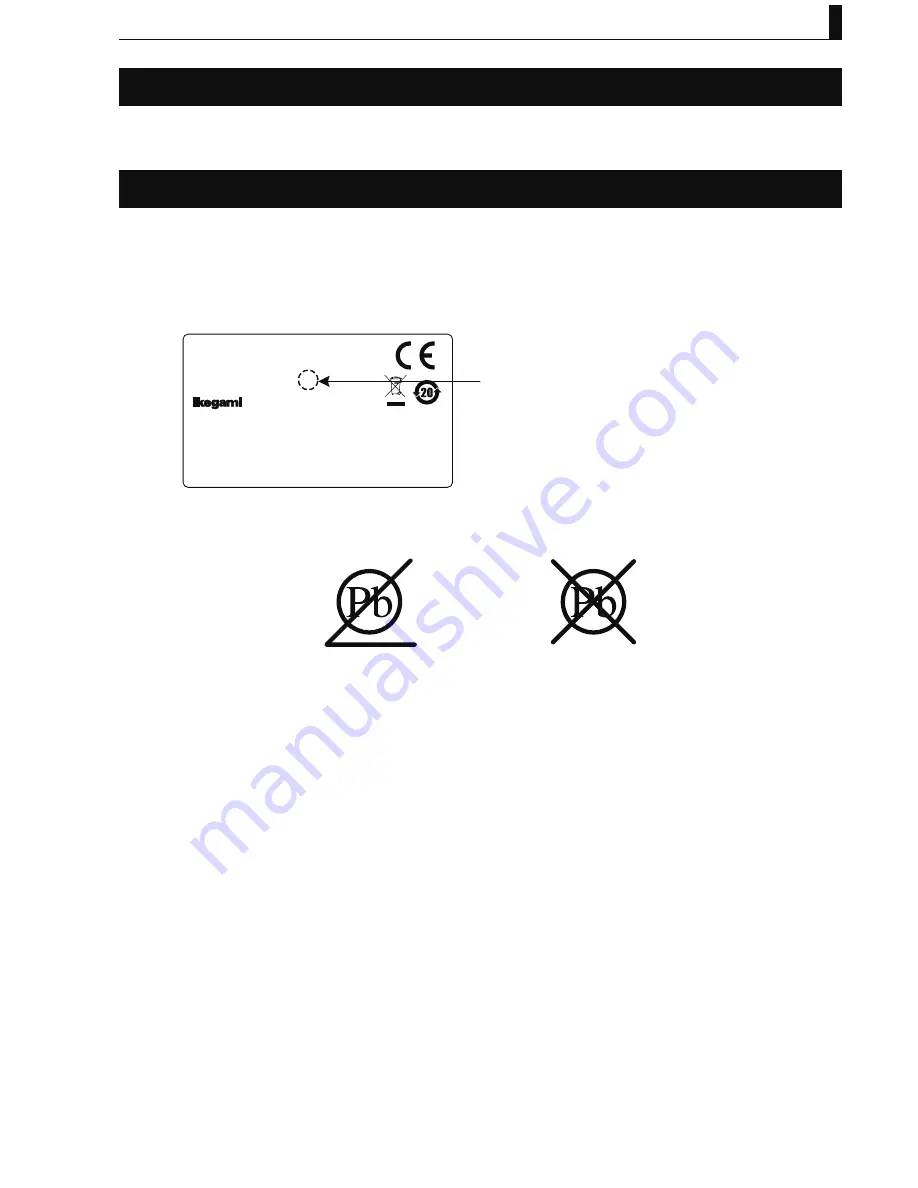

- For products conforming to RoHS directive, the letter “E” is appended at the end of the serial number on the label. For models

that the letter cannot be appended to the serial number, the letter “E” will be described in a distinguishable position on the label.

A description example on a main label is shown below.

Product conforming to RoHS directive

Label

MADE IN JAPAN

MADE IN JAPAN

SER No.

SER No.

MULTI PURPOSE CAMERA

UHL-43

AA123456E

THIS DEVICE COMPLIES WITH PART 15 OF THE

FCC RULES.OPERATIONS IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS:(1) THIS DEVICE

MAY NOT CAUSE HARMFUL INTERFERENCE,AND(2)

THIS DEVICE MUST ACCEPT ANY INTERFERENCE

THAT MAY CAUSE UNDESIRED OPERATION.

- The printed circuit boards of the RoHS compliant products have ether of the following marks with serigraph or label.

Phase 3

Phase 3A

2. Soldering

Since the melting point of lead-free solder used for the products conforming to RoHS directive is 20 to 45 degrees Celsius higher

than that of conventional solder with lead (Sn-Pb eutectic solder), a high temperature needs to be set to a soldering iron. Taking

allowable temperature limit of the parts and stable work into consideration, use a soldering iron with excellent thermal recovery

characteristics.

- Recommended solder composition is “Sn/3.0Ag/0.5Cu” or equivalent.

- Separate the soldering iron exclusively for RoHS products and the soldering iron for conventional use.

- Set the temperature of the soldering bit to 350 to 370 degrees Celsius.

The temperature may need to be adjusted according to the size of the copper foil land on the print-circuit board and the tip width

of the soldering bit.

- Finish by a lead-free solder looks dull or whitish compared to conventional solder with lead.

- If the customer mixed the lead-solder with the main body wiring or the circuit board, it becomes guarantee off the subject.

Ikegami doesn't guarantee to do the repair work. Because the solder polluted with lead cannot be removed.

3. Parts

Be sure to use parts conforming to RoHS directive.