29

Distance between oil nozzle and baffle plate as well as position of

the baffle plate in the burner pipe

The distance between oil nozzle and baffle plate is 4mm for all combustion

capacities and versions of the mixing unit. This distance can be adjusted

by inserting the supplied hexagon socket screw (wrench size 4mm) bet-

ween the baffle plate and the oil nozzle. Alternatively to this adjustment

method, a distance washer with a thickness of 2.5mm is offered which

can be pushed onto the oil pre-heater serving as mechanical stop for the

baffle plate and thus ensuring the compliance with the distance of 4mm

between baffle plate and oil nozzles.

The position of the baffle plate in the burner pipe is defined by the distance

between the outlet edge of the burner pipe and the bottom of the baffle

plate. This distance can be measured with a depth gauge. For easy ad-

justment of the baffle plate position, an adjustment screw with appropriate

millimetre scale is provided at the rear side of the housing. The calibration

of the scale defines the distance between burner pipe and baffle plate at

the scale value 0.

Mixing units A/B:

Scale value 0

‰

15 mm of distance between burner pipe and baffle plate

Mixing units E/F:

Scale value 0

‰

17 mm of distance between burner pipe and baffle plate

All resulting scale values for the basic adjustment of the baffle plate

are provided as reference values in the basic adjustment table (see

chapter 5).

Adjustment of the combustion air flow

Provided that the correct mixing unit has been selected with regard to the

required combustion capacity and that the distance between oil nozzle

and baffle plate is also in compliance with the specifications, the

combustion air flow is adjusted with the air regulator and the baffle plate.

Adjustments should preferably be made with the set screw of the air

regulator. The scale values for the basic adjustment of the air regulator

and the baffle plate are provided as reference values in the basic adjust-

ment table (see chapter 5).

Air regulator

By turning the set screw for the air regulator counterclockwise, the air

flow from the blower is reduced and the blower pressure measured at

the pressure measuring nipple decreases, and the CO

2

content in the

exhaust air increases. Turning the set screw clockwise will open the

regulator and increase the blower pressure, thus reducing the CO

2

con-

tent in the exhaust air.

Baffle plate

By turning the set screw for the baffle plate clockwise, the ring gap bet-

ween burner pipe and baffle plate is reduced thus reducing the combus-

tion air volume with increasing blower pressure and increasing the CO

2

content of the exhaust air.

For reverse direction of rotation, the gap width and thus the combustion

air volume increases with decreasing blower pressure thus decreasing the

CO

2

content in the exhaust gas.

Blower pressure

A pressure measuring nipple is provided at the nozzle fitting cover for

measuring blower pressure. Reference values for blower pressure are pro-

vided in the basic adjustment table (see chapter 5). Make sure to observe

a blower pressure between 2.0 and 3.5mbar.

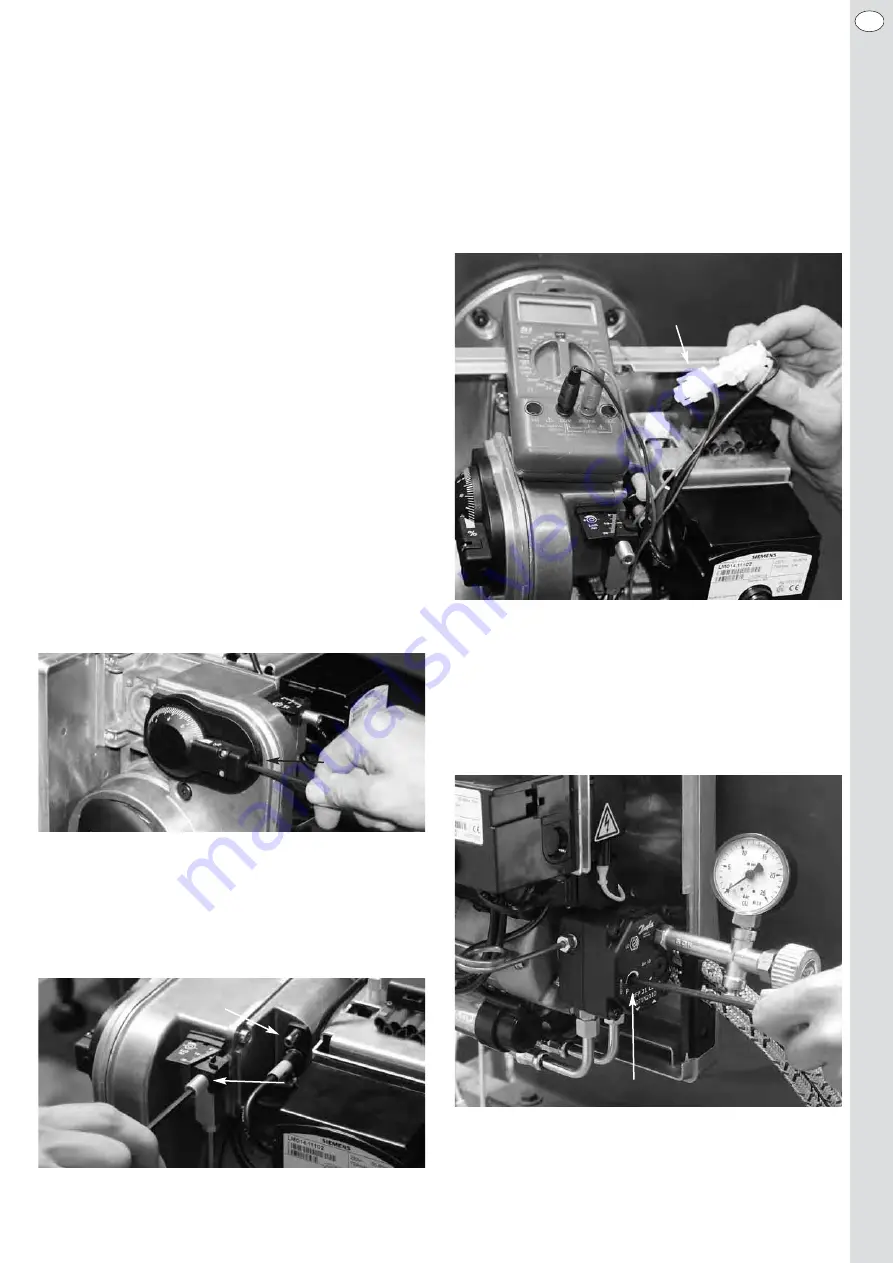

Photoelectric current

The photoelectric current must be measured in series with the photo

conductive cell (positive pole on terminal 12 with an internal resistance of

the measuring instrument of max 5k k

액

) using a DC micro amperemeter.

During operation, the photoelectric current must amount to 55 A and 100

μA at 230 V~. For this purpose, we recommend the measuring adapter

with order no. 10042.00010 which can be supplied as an accessory (see

chapter 10.1).

Adjustment of the oil mass flow

The injected oil mass flow is calculated from the size of the nozzle and

the injection pressure set at the pressure controller of the oil pump.

By turning the set screw clockwise, the oil pressure increases and thus

the injected oil mass flow increases, too. By turning the set screw

counterclockwise, the oil pressure is reduced. A pressure gauge

connection is provided at the pump for measuring the blower pressure.

The pump test kit shown in chapter 10.3 includes all pressure measuring

devices as well as connecting pieces. Reference values for nozzle size

and oil pressure are provided in the basic adjustment table (chapter 5).

EN

Set screw

Air regulator

Set screw

Baffle plate

Pressure

measuring nipple

Oil pressure set screw

Measuring

adapter

Содержание HL 60 ALV.2

Страница 15: ...15 DE 7 Explosionszeichnung mit Ersatzteilliste...

Страница 20: ...20 DE 9 Brennerabmessungen HL 60 ALV 2 BLV 2 Schiebeflansch HL 60 ALV 2 BLV 2 Unitflansch...

Страница 21: ...21 DE 9 Brennerabmessungen HL 60 ELV 2 S FLV 2 S Schiebeflansch HL 60 ELV 2 S FLV 2 S Unitflansch...

Страница 33: ...33 EN 7 Expanded view with spare parts list...

Страница 38: ...38 EN 9 Burner dimensions HL 60 ALV 2 BLV 2 sliding flange HL 60 ALV 2 BLV 2 unit flange...

Страница 39: ...39 EN 9 Burner dimensions HL 60 ELV 2 S FLV 2 S sliding flange HL 60 ELV 2 S FLV 2 S unit flange...

Страница 51: ...51 FR 7 Vue clat e avec liste des pi ces de rechange...

Страница 56: ...56 FR 9 Dimensions du br leur HL 60 ALV 2 BLV 2 Bride coulissante HL 60 ALV 2 BLV 2 Bride unitaire...

Страница 57: ...57 FR 9 Dimensions du br leur HL 60 ELV 2 S FLV 2 S Bride coulissante HL 60 ELV 2 S FLV 2 S Bride unitaire...

Страница 69: ...69 IT 7 Disegno esploso con elenco parti di ricambio...

Страница 74: ...74 IT 9 Dimensioni bruciatore HL 60 ALV 2 BLV 2 Flangia scorrevole HL 60 ALV 2 BLV 2 Flangia unitaria...

Страница 75: ...75 IT 9 Dimensioni bruciatore HL 60 ELV 2 S FLV 2 S Flangia scorrevole HL 60 ELV 2 S FLV 2 S Flangia unitaria...