30

4.

Maintenance of the burner

When maintenance is required, loosen the clamping screw at the flange

by means of the hexagon key by 4mm, turn the burner to the left and pull

it out from the burner pipe. Subsequently, you should fit the burner to the

service screw of the flange using the lug in the base plate (version with

cover hood) or the lug at the burner housing (version without cover hood).

Easy access to all components around the mixing unit is ensured in this

so-called service position.

Attention:

Baffle plate and ignition electrodes may be very hot. Risk of injury!

Service position

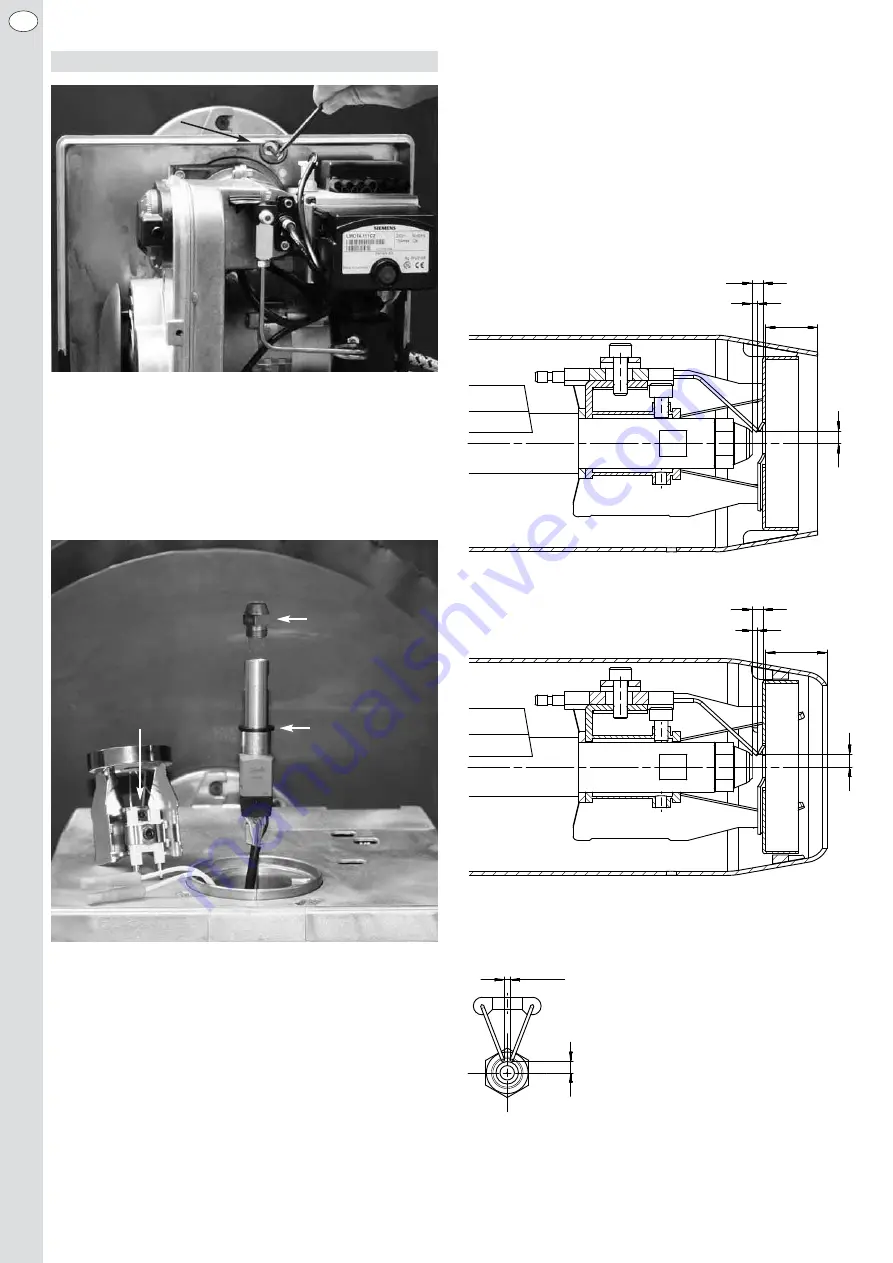

Replacement of nozzle and diaphragm valve

– Loosen the mounting screw for the baffle plate by 4mm using a hexagon

socket wrench and remove the baffle plate.

– Select an appropriate oil nozzle according to the basic adjustment table

(see chapter 5).

– Unscrew the existing oil nozzle.

– Inspect the used nozzle for burners with mixing unit E and F: If there

are traces of major thermal load (coke deposits on the outer coating,

rubber-like coke products on the nozzle filter), we recommend the

replacement of the diaphragm valve as well. To this end, remove the

diaphragm valve from the oil pre-heater using a M5 screw and insert a

new diaphragm valve (order no. 10021.00003). For the easy replace-

ment of the diaphragm valve, a knurled-head screw (order no.

10023.00026) is available as accessory.

– Screw in new oil nozzle.

– Mount the baffle plate to the oil pre-heater and adjust the distance

between baffle plate and oil nozzle according to the dimensional draw-

ing. A distance washer is mounted onto the oil pre-heater in the

factory, resulting in correct adjustment due to the limit stop. Alterna-

tively, the distance between baffle plate and oil nozzle can be adjusted

by inserting the supplied hexagon socket screw (wrench size 4mm)

between the baffle plate and the oil nozzle. Then locate the baffle plate

at the set position using the mounting screw.

– To ensure the reliable ignition of the mixture, the adjusting dimensions

of the ignition electrodes must be checked and readjusted according

to the dimensional drawing, if necessary.

Adjusting dimensions of mixing unit and ignition electrode

EN

4 mm

2 mm

15 – 35 mm

5 mm

4 mm

2 mm

17 – 37 mm

5 mm

2 – 3 mm

5 mm

A /B

A /B / E / F

E / F

Service screw

Oil nozzle

Mixing head

mounting screw

Distance washer

Содержание HL 60 ALV.2

Страница 15: ...15 DE 7 Explosionszeichnung mit Ersatzteilliste...

Страница 20: ...20 DE 9 Brennerabmessungen HL 60 ALV 2 BLV 2 Schiebeflansch HL 60 ALV 2 BLV 2 Unitflansch...

Страница 21: ...21 DE 9 Brennerabmessungen HL 60 ELV 2 S FLV 2 S Schiebeflansch HL 60 ELV 2 S FLV 2 S Unitflansch...

Страница 33: ...33 EN 7 Expanded view with spare parts list...

Страница 38: ...38 EN 9 Burner dimensions HL 60 ALV 2 BLV 2 sliding flange HL 60 ALV 2 BLV 2 unit flange...

Страница 39: ...39 EN 9 Burner dimensions HL 60 ELV 2 S FLV 2 S sliding flange HL 60 ELV 2 S FLV 2 S unit flange...

Страница 51: ...51 FR 7 Vue clat e avec liste des pi ces de rechange...

Страница 56: ...56 FR 9 Dimensions du br leur HL 60 ALV 2 BLV 2 Bride coulissante HL 60 ALV 2 BLV 2 Bride unitaire...

Страница 57: ...57 FR 9 Dimensions du br leur HL 60 ELV 2 S FLV 2 S Bride coulissante HL 60 ELV 2 S FLV 2 S Bride unitaire...

Страница 69: ...69 IT 7 Disegno esploso con elenco parti di ricambio...

Страница 74: ...74 IT 9 Dimensioni bruciatore HL 60 ALV 2 BLV 2 Flangia scorrevole HL 60 ALV 2 BLV 2 Flangia unitaria...

Страница 75: ...75 IT 9 Dimensioni bruciatore HL 60 ELV 2 S FLV 2 S Flangia scorrevole HL 60 ELV 2 S FLV 2 S Flangia unitaria...