25

In this process, the baffle plate separates the combustion air into three

air flows. The centrally flowing primary air supplies the flame root with

combustion air. Secondary air is made rotate by radially arranged and po-

sitioned slots in the baffle plate in order to provide the continuous mixing

and distribution of combustion air with finest fuel fog. The third air flow

through the circular orifice between burner tube and baffle plate supplies

combustion air to the flame coat.

The flow speed as well as the back pressure in the mixing unit, among

others, can be influenced by adjusting the pressure panel position in the

burner tube.

Depending on the combustion capacity, a 4-slot or 12-slot baffle plate

is provided for the mixing device. For standard burner models, these

baffle plates are combined with a burner tube with a conically shaped

nozzle piece (mixing system A and B). Nitrogen oxide emissions are

further reduced by additionally swirling the tertiary air flowing in through

the outer edge of the baffle plate. To this end, the burner tube is provided

with slanted guide arms at the conical nozzle piece. Moreover, the air

flow is guided via an air-flow breakaway edge which is positioned

vertically to the direction of flow. Such a burner tube combined with both

baffle plates makes up the mixing systems E and F.

A

Burner tube

B Oil

pre-heater

C Ignition elec -

trodes

D Oil

nozzle

E baffle

plate

F Initial air to the

flame root

G Tertiary air to

the flame coat

H Secondary

air

swirled for

mixing

2.2 Combustion air blower

Combustion air is delivered through a patented hybrid blower which

features extremely high compressive strength. This ensures the start-up

of the burner without pulsation and delays, in particular in the case of

high combustion chamber backpressures. In comparison with con -

ventional blower solutions, the high degree of efficiency of the blower

results in the significant reduction of electric energy consumption.

For operation dependent on ambient air, the protective cover at the

blower inlet can be replaced by a intake air silencer which is available

as an accessory. Intake ports with Ø 50mm or Ø 80mm are available for

operation independent of ambient air. Moreover, a pivoted intake port

with Ø 50mm is offered which can be combined with an upstream

silencer.

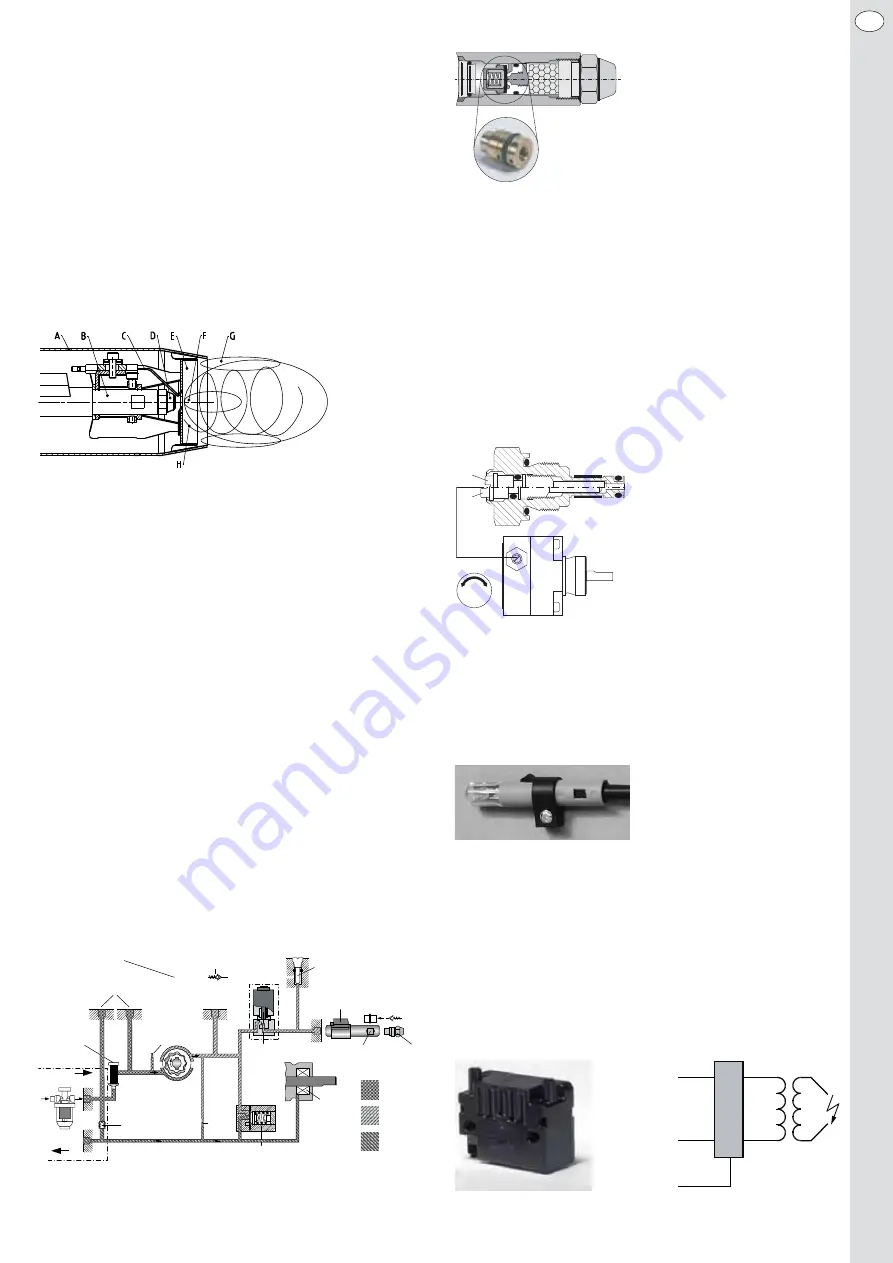

2.3 Fuel pump and nozzle closing system

A gear wheel pump is used as fuel pump. The picture shows the hydrau-

lic diagram of a 1-stage fuel pump. The gear wheel set of the pump

delivers fuel from a storage tank of the the oil supply system through a

cartridge filter to the oil nozzle. The required injection pressure is adjus-

ted with a pressure control valve. A magnetic valve is provided for the

control of the injection process. If no power is applied, the magnetic

valve is closed. In this switching status, the whole fuel flows back

through the pressure control switch to the storage tank. For fuel

injection, power is supplied to the magnetic valve and it opens up. Now

fuel flows to the nozzle with the pressure set at the pressure control

valve.

In order to reduce start-up and switch-

off emissions, burner models with mixing

units E and F are equipped with a Dan-

foss nozzle closing system (LESystem)

as a standard. To this end, a spring-

loaded diaphragm valve is installed in

the oil pre-heater which opens at an oil

pressure of approximately 5 bar and is

closed by spring force at approximately

3 bar. In order to accelerate the closing

process of the valve when switching off the burner and to prevent the

increase of pressure in the nozzle line by external influences (e.g. fuel pre-

heating for burner start-up, combustion chamber radiation after burner

switch-off), respectively, the LE oil pump is equipped with a bypass

channel between pressure and intake side for pressure release. A spring-

loaded pressure relief valve with an opening pressure of 2 bar is integrated

in the bypass channel. Due to temperature-related volumetric expansion,

the pressure in the oil pre-heater increases. As soon as the pressure

exceeds 2 bar, the pressure relief valve in the bypass channel of the pump

opens. However, the diaphragm valve in the pre-heater remains closed

due to the higher opening pressure thus preventing fuel from escaping.

After the pre-heating phase, the burner motor is started resulting in

pressure generation within the pump up to the value set at the pressure

controller. After pre-aeration, the magnetic valve is opened. The injection

pressure which builds up in the oil pre-heater opens the diaphragm valve.

Thus, the injection process is started in a controlled way at the opening

pressure given by the diaphragm valve. As the pressure drop at the dia-

phragm valve can be neglected, the pressure at the oil nozzle is equivalent

to the pressure measured at the pump. In order to keep the partial flow

through the bypass during the operation

of the burner as low as possible, an ad-

ditional cover plate is integrated in the

bypass channel. As soon as the burner

switches off, the magnetic valve closes

and the injection pressure is relieved

through the nozzle. As soon as the pres-

sure falls below 3 bar, the diaphragm

valve in the oil pre-heater is closed. This

ensures the controlled end of the in-

jection process without delayed dripping.

The LE oil pump can also be used as

standard oil pump. The LE system can

be activated and/or deactivated by tur-

ning the setting screw (see illustration).

2.4 Flame monitoring

Flame monitoring for HL60 A/B/E/F is implemented with flame sensors of

different degrees of sensitivity especially suited for oil burners with yellow

flame.

Optical flame detectors, LDS blue and LDS red

The Danfoss light-depending resis-

tance sensor (photo conductive cell)

LDS is used for flame monitoring. If

constant voltage is applied, a

changing current depending on the in-

tensity of flame radiation can be mea-

sured which is referred to as photoelectric current. There are two designs

depending on sensitivity. The low-sensitive Danfoss flame sensor LDS red

(red sensor housing) is used for flames with intensive yellow colour and

thus with a high degree of radiation for the mixing devices A and B. The

more transparent flames of the emission-optimised mixing devices E and

F require the use of the high-sensitive Danfoss flame sensor LDS blue

(blue sensor housing).

2.5 Ignition device

The ignition of the mixture by means of a separate ignition device (Danfoss

EBI 4). An earth connection is provided in the primary connection socket

to achieve low electromagnetic interference emissions, i.e. the connection

socket has 3 poles (phase, neutral wire and earth).

Blue, N

Secondary

voltage:

15 kV

Brown, voltage

supply, L1

Ignition

"On": 230 V AC

"Off": 0 V

PE, earthing

50/60 Hz

20 kHz

EN

Ì>iÊÃ`i

*ÀiÃÃÕÀiÊÃ`i

,iÌÕÀÊvÜ

Þ«>ÃÃÊV >i

i>ÃÕÀ}Ê«ÕÌÊ>ÌÊ

Ì

iÊ«ÀiÃÃÕÀiÊÃ`i

i>ÃÕÀ}Ê«ÕÌÊ>ÌÊ

Ì

iÊÌ>iÊÃ`i

ÛiÀÊ«>Ìi

ÛiÀÊ

«>Ìi

>ÀÌÀ`}iÊvÌiÀ

-iÌÌ}ÊÃVÀiÜÊvÊÌ

iÊ

ÊÃÞÃÌi

"Ê«Ài i>ÌiÀ

"Êââi

>«À>}ÊÛ>ÛiÊ

«ÊrÊxL>À

- >vÌÊÃi>

*ÀiÃÃÕÀiÊÛ>Ûi

*ÀiÃÃÕÀiÊÀiivÊÛ>ÛiÊ«ÊrÊÓL>À

>}iÌVÊÛ>Ûi

V}ÊÃVÀiÜÊvÀÊ

ÃÜÌV

}ÊvÀÊiiÊ

«iÀ>ÌÊÌÊÌÜiÊ

«iÀ>Ì

iVÌÊ

ÊÃÕ««ÞÊ

Hydraulic diagram of 1-stage oil pumps

Mixing device

ON

OFF

ON

OFF

LE

Activation / deactivation

of the LE system

LE

diaphragm

valve

Содержание HL 60 ALV.2

Страница 15: ...15 DE 7 Explosionszeichnung mit Ersatzteilliste...

Страница 20: ...20 DE 9 Brennerabmessungen HL 60 ALV 2 BLV 2 Schiebeflansch HL 60 ALV 2 BLV 2 Unitflansch...

Страница 21: ...21 DE 9 Brennerabmessungen HL 60 ELV 2 S FLV 2 S Schiebeflansch HL 60 ELV 2 S FLV 2 S Unitflansch...

Страница 33: ...33 EN 7 Expanded view with spare parts list...

Страница 38: ...38 EN 9 Burner dimensions HL 60 ALV 2 BLV 2 sliding flange HL 60 ALV 2 BLV 2 unit flange...

Страница 39: ...39 EN 9 Burner dimensions HL 60 ELV 2 S FLV 2 S sliding flange HL 60 ELV 2 S FLV 2 S unit flange...

Страница 51: ...51 FR 7 Vue clat e avec liste des pi ces de rechange...

Страница 56: ...56 FR 9 Dimensions du br leur HL 60 ALV 2 BLV 2 Bride coulissante HL 60 ALV 2 BLV 2 Bride unitaire...

Страница 57: ...57 FR 9 Dimensions du br leur HL 60 ELV 2 S FLV 2 S Bride coulissante HL 60 ELV 2 S FLV 2 S Bride unitaire...

Страница 69: ...69 IT 7 Disegno esploso con elenco parti di ricambio...

Страница 74: ...74 IT 9 Dimensioni bruciatore HL 60 ALV 2 BLV 2 Flangia scorrevole HL 60 ALV 2 BLV 2 Flangia unitaria...

Страница 75: ...75 IT 9 Dimensioni bruciatore HL 60 ELV 2 S FLV 2 S Flangia scorrevole HL 60 ELV 2 S FLV 2 S Flangia unitaria...