GSK988TA/GSK988TA1/GSK988TB Turning Center CNC System User Manual

【

Programming & Operation

】

92

Ⅰ

Programming

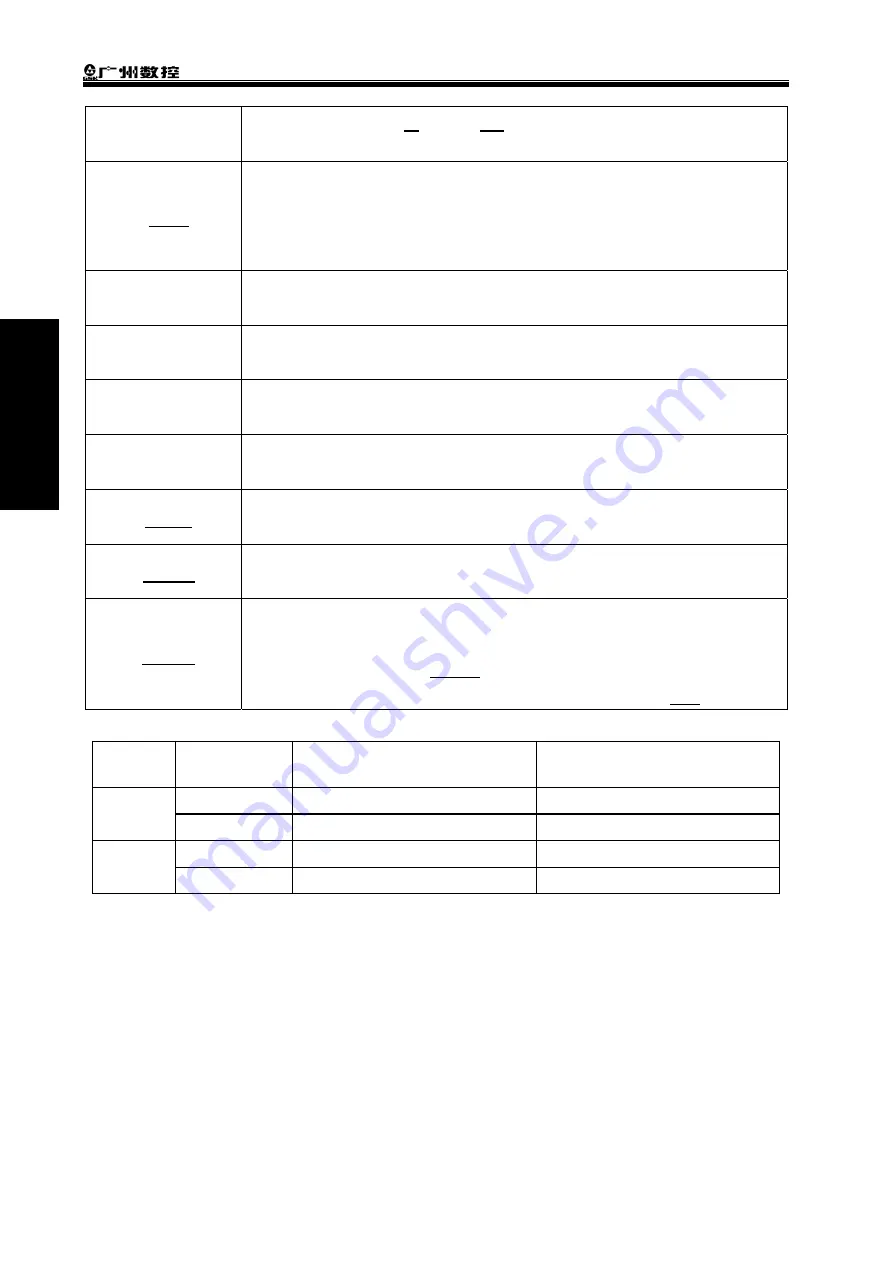

Cutting end point

It is defined by X

(

U

)

Z

(

W

)

,and is the end point B

f

of last axial tool

infeed

R

(

e

)

It is the travel of tool retraction after each axial (Z) tool infeed without sign

symbols as the following table. The code value is reserved after executing R

(

e

)

and the value of NO.5139 is rewritten. The value of NO.5139 is

regarded as the travel of tool retraction when R

(

e

)

is not input

X

absolute coordinate value of the 2

nd

axis (X in ZX plane) in path diagram B

point

U

Relative movement amount of the 2

nd

(U in ZX plane) in path diagram A

→

B

plane.(for G code system A. X_,Z_ is executed for other conditions)

Z

absolute coordinate value of the 1

st

axis (Z in ZX plane) in path diagram C

point

W

Relative movement amount of the 2

nd

(W in ZX plane) in path diagram A

→

C

plane. (for G code system A. X_,Z_ is executed for other conditions)

P

(

∆

i

)

Travel of radial(X) cutting for each axial cutting cycle without sign symbols,

and the value range is referred to the following table

Q

(

∆

k

)

Travel of Z discontinuous tool infeed without sign symbols in axial(Z) cutting,

and the value range is referred to the following table

R

(

∆

d

)

Travel (radius value) of radial (X) tool retraction after cutting to end point of

axial cutting. The value range is referred to the following table. The radial (X)

tool retraction is 0 when R

(

∆

d

)

is omitted and the system defaults the axial

cutting end point. The radial (X) tool retraction is 0 when P

(

∆

i

)

is omitted

Address

Incremental

system

metric

(

mm

)

input

Inch (inch) input

ISB system

1~99999999(unit

:

0.001mm) 1~99999999(unit

:

0.0001inch)

P(

∆

i)

Q(

∆

k)

ISC system

1~99999999(unit

:

0.0001mm) 1~99999999(unit

:

0.00001inch)

ISB system

0

~

99999.999mm 0

~

9999.9999 inch

R(e)

R(

∆

d)

ISC system

0

~

9999.9999 mm

0

~

999.99999 inch

Содержание GSK988TA

Страница 6: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation VI ...

Страница 19: ...1 Ⅰ Programming PROGRAMMING ...

Страница 20: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 2 Ⅰ Programming ...

Страница 176: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 158 Ⅰ Programming ...

Страница 227: ...209 Ⅱ Operation OPERATION ...

Страница 228: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 210 Ⅱ Operation ...

Страница 242: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 224 Ⅱ Operation ...

Страница 298: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 280 Ⅱ Operation ...

Страница 336: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 318 Ⅱ Operation ...

Страница 348: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 330 Ⅱ Operation ...

Страница 352: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 334 Ⅱ Operation ...

Страница 358: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 340 Ⅱ Operation ...

Страница 369: ...Chater 10 Machining Example 351 Ⅱ Operation ...

Страница 370: ...GSK988TA GSK988TA1 GSK988TB Turning Center CNC System User Manual Programming Operation 352 Appendix APPENDIX ...

Страница 371: ...353 Appendix ...

Страница 465: ...Appendix 1 Parameters 447 Appendix ...

Страница 479: ...Appendix 3 Interface Explanation 461 Appendix ...

Страница 527: ...Appendix 5 Installation Layout 509 Appendix ...