5-29

In general, specify data of function code F20 at a value close to the rated slip

frequency of motor. If you set it at an extremely high value, control may become

unstable and an overvoltage alarm may result in some cases.

The DC brake function of the inverter does not provide any holding mechanism.

Injuries could occur.

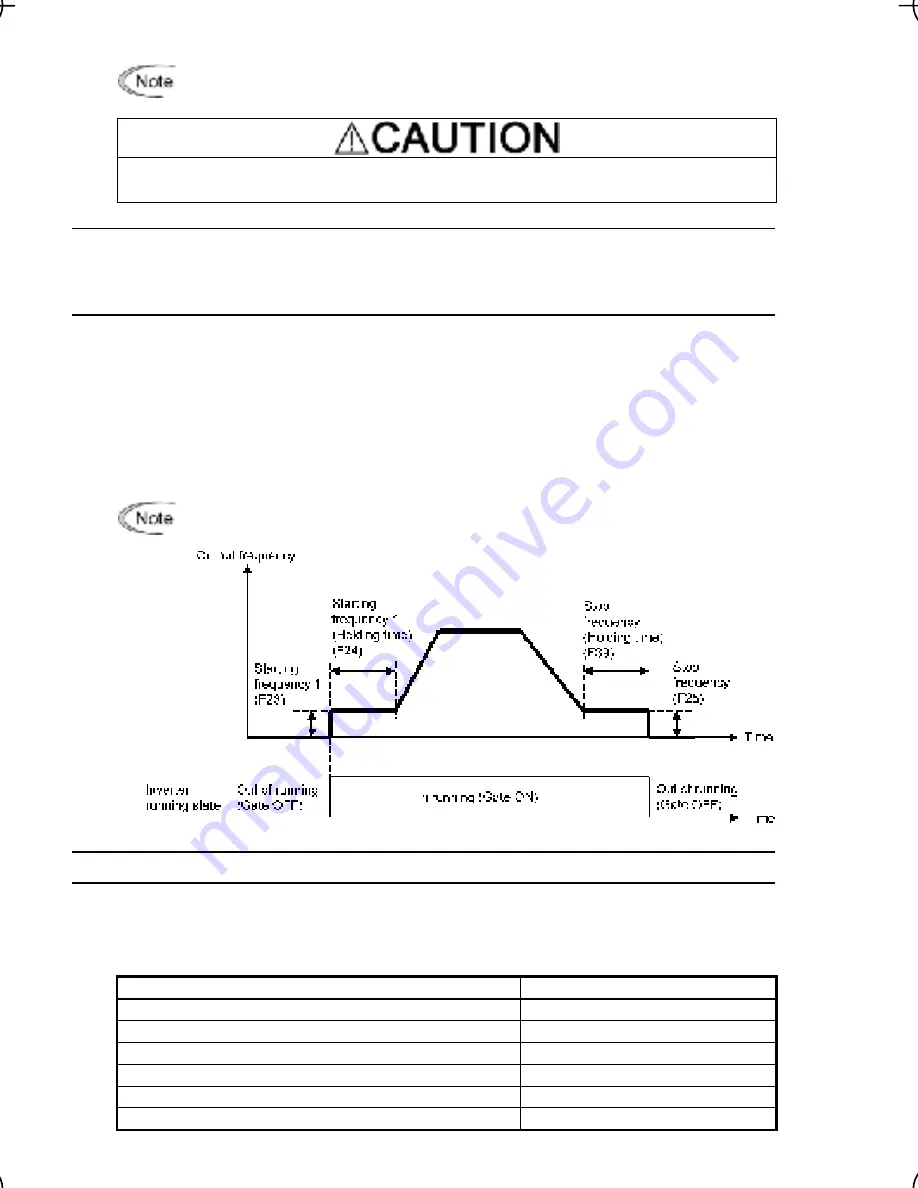

F23

Starting Frequency 1

Starting Frequency 1 (Holding time)

Stop Frequency

Stop Frequency (Holding time)

F24

F25

F39

At the startup of an inverter, the initial output frequency is equal to the starting frequency 1

specified by F23. The inverter stops its output when the output frequency reaches the stop

startup.

shment of a magnetic flux in the motor. F39 specifies the

frequency

Set the st

specified by F25.

arting frequency to a level at which the motor can generate enough torque for

Generally, set the motor's rated slip frequency as the starting frequency.

In addition, F24 specifies the holding time for the starting frequency 1 in order to compensate

for the delay time for the establi

holding time for the stop frequency in order to stabilize the motor speed at the stop of the

motor.

If the starting frequency is lower than the stop frequency, the inverter will not output

any power as long as the reference frequency does not exceed the stop frequency.

F26, F27

Motor Sound (Carrier frequency and tone)

Motor sound (C

F26 co

s the

b

electromagnetic

ec

main output (sec

Carrier frequency

arrier frequency) (F26)

ntrol

carrier frequency so as to reduce an audi

noise from the inverter itself, and to d

ondary) wirings.

le noise generated by the motor or

rease a leakage current from the

0.75 to 15 kHz

Motor sound noise emission

High

↔

Low

Motor te

mponents)

High

↔

Low

mperature (due to harmonics co

Ripples in output current waveform

Large

↔

Small

Leakag

Low

↔

High

e current

Electromagnetic noise emission

Low

↔

High

Inverter loss

Low

↔

High