6. Control Operation and Description

Rebel

80

29

recalculate the remaining number of pieces left on the bar. The measurement is also needed for

the bar feeder to determine the end of the rapid travel forward when the signal is activated.

The lathe collet must be closed before the measuring process can begin. If the collet is not

closed the bar feeder screen will display a message instructing the operator to close the collet.

The “Bar Feeder in Automatic” signal to the lathe will not be given until the measurement cycle

is completed.

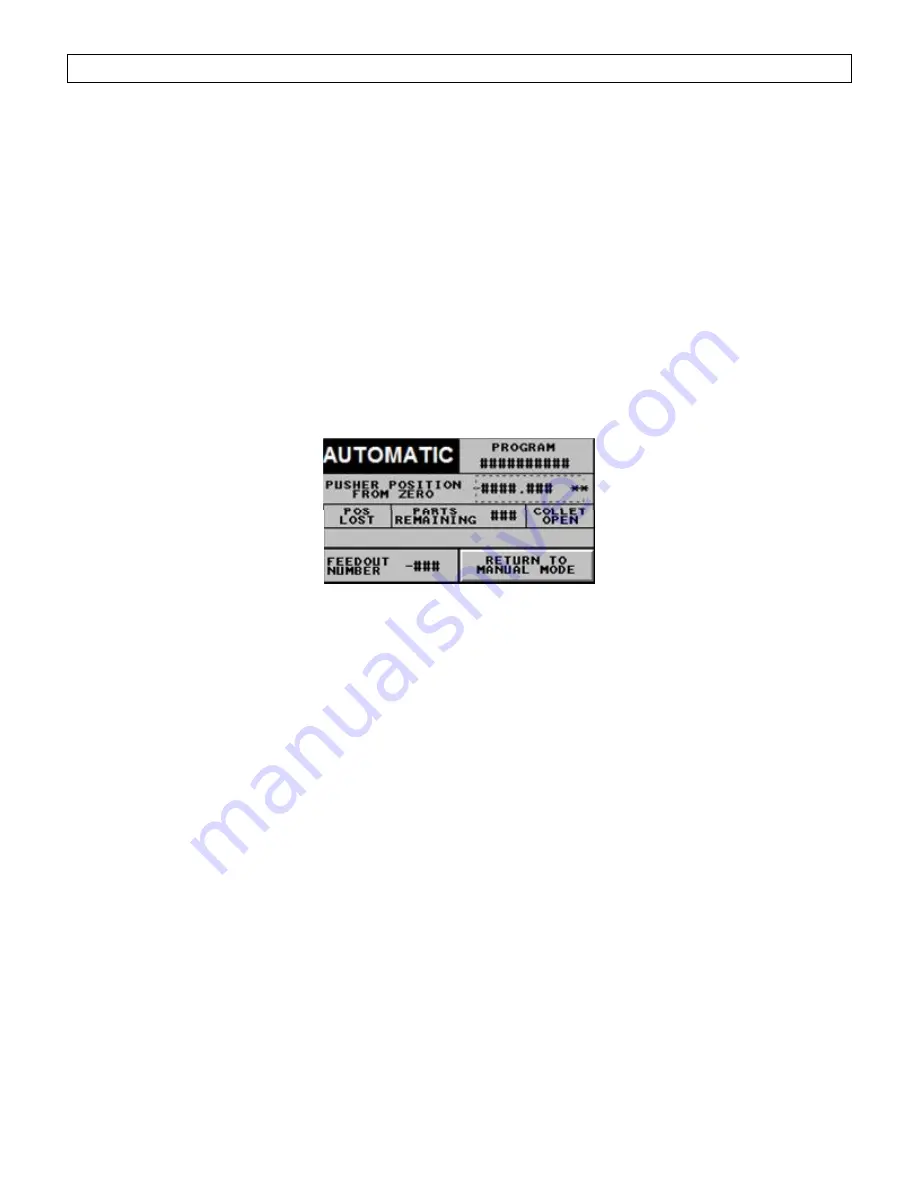

6.3.10 Automatic Screen Functions

The Automatic screen allows the operator to monitor the location of the bar pusher and the

remaining number of parts that can be made from the material in the lathe spindle by selecting

the selecting dual active switch. Whichever parameter is active touching the key will change to

the next parameter. As on the Manual screen the status of the lathe collet, channel position and

active program number are displayed. The banner above the Manual button shows the current

operation of the bar feeder.

The bar feeder can be switched from Automatic mode to Manual mode by pressing the “Return

to Manual mode”. This is the only function that can be controlled from this screen. The

remainder of the screen is for status monitoring.