4. Installation

Rebel

80

15

·

Place the bar on the V-tray and raise the V-tray to position using the tray up button.

·

Slide the stock toward the spindle.

·

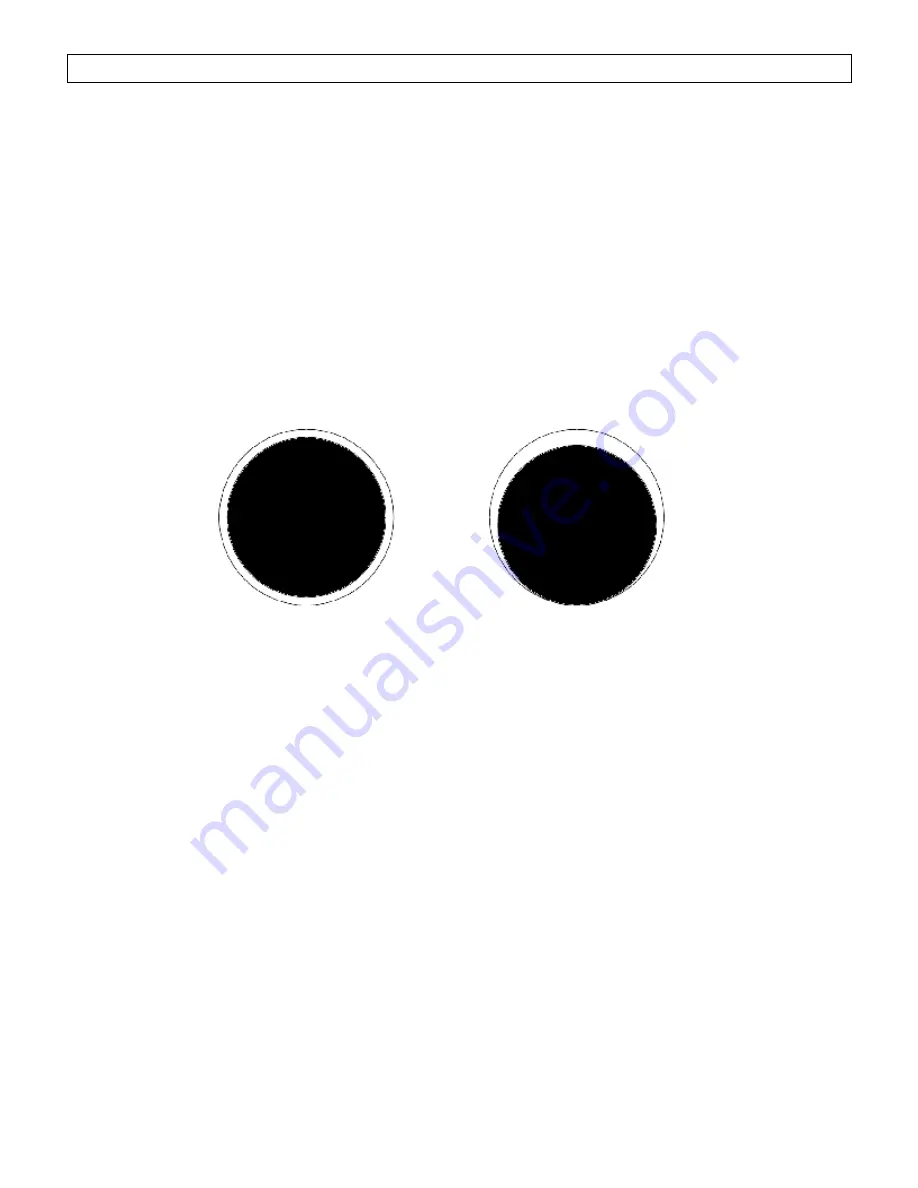

Look into the spindle from the chuck end and observe the ring of light around the bar

stock. Move the bar feeder so the ring is equal all around the stock.

·

Once the bar is centered at the end of the spindle push it into the lathe.

·

Looking through the spindle from the chuck the goal is to have the bar equally spaced

from the sides.

·

The bar will rest on the bottom of the bore as it moves further into the spindle. This is not

a problem as long as the bar moves freely.

Bar centered in spindle Resting on bottom of spindle

4.6

Anchoring the bar feeder

When the alignment is correct the bar feeder must be anchored to the floor to prevent it from

moving out of position. The bar feeder is supplied with ½” diameter anchor bolts to secure the

axial track to the floor. It is recommended to drill the holes for the anchor bolts through the floor

if possible or at least as deep as the anchor bolt is long so that the bolt may be driven flush with

the floor should the machine need to be moved. Alignment should be rechecked after anchoring

the bar feeder to the floor to make sure the alignment has not changed.

Small adjustments to the alignment can be made by the leveling nuts on the leveling feet.