Owners Manual Ecosaire

®

EN Series Precision Air Conditioner

Ecosaire

®

July 2009 35

Data subject to change without notice.

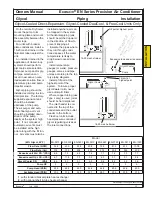

On the remote DryCooler,

mount the pump to its

mounting plate and mount

the assembly between the

cooler legs.

For units with brazed-

plate condensers, install a

16-20 mesh strainer in the

fluid-inlet tube nearest the

unit.

An installer trained in the

application of closed-loop

systems should perform

glycol-pipe size selection.

Improper pump and/or gly-

col pipe selection can

result in excessive noise,

inadequate solution flow or

premature pipe and pump

impeller erosion.

Glycol piping should be

installed according to stan-

dard practice. The factory-

supplied expansion tank

should be installed

upstream of the pump.

The air purger and auto-

matic float-type air vent

should be installed down-

stream of the pump -

ideally at the system high

point. If not, manual or

automatic air vents must

be installed at the high

point along with the fill fun-

nel. Air vents must also be

installed anywhere air can

be trapped in the system.

All horizontal piping runs

should be pitched upward

in the direction of flow to

prevent trapping air.

Insulate the pipes where

they run through condi-

tioned spaces if the water

temperature is likely to

drop below room-air dew

point.

Install temperature

gauges (or wells), pressure

gauges, valves, and pipe

unions according to the fac-

tory piping diagrams.

Install a fill port at the

highest point of the

system. To insure proper

glycol/water ratio, never

use automatic fillers.

Where copper tubing (use

Type L only) is used, joints

should be hard soldered.

The inlet header is con-

nected to the top of the

condensers and the outlet

header to the bottom.

FreeCool units include

head-pressure-controlled

glycol regulating valves at

the inlet connections.

Fill port at highest point.

16-20 mesh strainer

Pump

Glycol Cooler

Glycol Cooler

Expansion tank and air separator

16-20 mesh strainer

Fill port at

highest point.

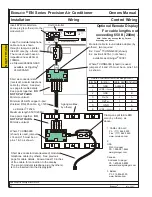

34.8

40.9

53.8

60.8

72.5

81.4

91.3

107.8

6.8

7.3

6.9

7.4

7.1

7.2

7.5

7.7

6.7

11.8

7.0

3.9

6.3

3.1

3.1

8.8

6.4

3.7

3.7

2.5

9.6

8.8

4.2

3.9

2

2

3

3

3

5

5

5

Model

EN-027F

EN-035F

EN-042F

EN-051F

EN-068F

EN-079F

EN-087F

EN-102F

Flow Rate (GPM)

132

155

204

230

274

308

346

408

Flow Rate (l/m)

Ecosaire unit Std. P.D.

1

(PSI)

Ecosaire unit Opt. P.D.

2

(PSI)

Glycol Cooler P.D. (PSI)

Pump HP

43.5

42.6

43.5

42.6

44.8

43.5

42.6

43.5

Pump Head (PSIG)

30.3

31.6

32.9

32.7

28.1

27.5

30.9

31.9

Available Head (PSIG)

Glycol

Piping

Installation

Glycol-Cooled Direct-Expansion, Glycol-Cooled DualCool, & FreeCool Units Only

INST

ALLA

TION

Ecosaire

Ecosaire

EXAMPLE

Appearance, location, and

quantity of component

s

may vary

.

EXAMPLE

Appearance, location, and

quantity of component

s

may vary

.

(40% Glycol, 95°F)

1

. with standard brazed-plate heat exchanger

2

. with optional shell & tube heat exchanger

Содержание EN Series

Страница 1: ......

Страница 103: ...OEM User manual ...

Страница 104: ......

Страница 106: ......

Страница 108: ......

Страница 110: ......

Страница 115: ...OEM CAREL code 030221791 rel 2 1 21 09 07 7 KUE 4 L H A1 A2 S2 S1 V3 V1 P S V X X1 Y Y1 KUE CC ...

Страница 123: ...OEM CAREL code 030221791 rel 2 1 21 09 07 15 4 2 Single phase wiring diagram INTERNAL TAM CP2 ...

Страница 124: ...OEM CAREL code 030221791 rel 2 1 21 09 07 16 4 3 Single phase wiring diagram INTERNAL TAM with contactor CP4 ...

Страница 125: ...OEM CAREL code 030221791 rel 2 1 21 09 07 17 4 4 Single phase wiring diagram EXTERNAL TAM with contactor CP3 ...

Страница 126: ...OEM CAREL code 030221791 rel 2 1 21 09 07 18 4 5 Three phase wiring diagram EXTERNAL TAM with contactor CP3 ...

Страница 127: ...OEM CAREL code 030221791 rel 2 1 21 09 07 19 4 6 Three phase wiring diagram INTERNAL TAM with contactor CP4 ...

Страница 141: ......