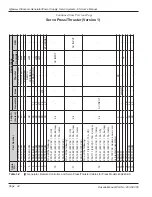

Pin 5 (Remote Setup Selection Bit 2 Input)

Pin 5 is the Remote Setup Selection Bit 2, which is the

third least significant bit used to select different welding

setups with an automation control system.

Pin 6

(Remote Setup Selection Bit 3 Input)

Pin 6 is the Remote Setup Selection Bit 3, which is the

second most significant bit used to select different weld-

ing setups with an automation control system.

Pin 7 (Remote Setup Selection Bit 4 Input)

Pin 7 is the Remote Setup Selection Bit 4, which is the

most significant bit used to select different welding setups

with an automation control system.

Pin 8

(Ultrasound Activation/ Cycle Start

Input)

Pin 8 is used to activate the generator ultrasound output.

Activation of this control input will switch the ultrasound

output ON, and deactivating this signal will switch ultra-

sound OFF. This input signal will also function as a cycle

start input, where the ultrasound activation and timing

are completely under the control of the process control-

ler. Depending on the welding process controller setup,

this input signal could be activated momentarily to start

a welding cycle.

Pin 9

(Not Used)

Pin 10

(Not Used)

Pin 11

(Press Inhibit for Hand Probes)

Pin 11 is used to disconnect power applied to a press or

thruster, if a hand probe is connected to the system input

connector, for safety considerations. The hand probe acti-

vation switch could unexpectedly start a welding cycle that

activates a press or thruster to the down position. The hand

probe cable connector is wired to apply chassis ground to

this pin, when it is attached to the system, which activates

a press inhibit relay that disconnects power from the pneu-

matic press valves. This pin must be left open whenever

a press control board is installed. Connecting this pin to

chassis ground will inhibit press operation.

Pin 12

(System Latch Reset Input)

Pin 12 is used to reset the Any Fault or System Overload

status outputs (See Status Output descriptions). If a fault

occurs during a weld cycle, these outputs will normally

remain active until the next weld cycle is initiated. Activat-

ing this input will reset the status output faults and may

simplify automation programming.

NOTE

Refer to

Latch on Bad Part,

on Page 51 for

more information.

Pin 13

(Isolated Common)

Pin 13 is electrically isolated from chassis ground. Using

isolated sourcing (PNP) output drivers, this common line

would be connected to isolated ground potential. Using

isolated sinking (NPN) output drivers, this common line

would be connected to the isolated positive supply volt-

age output.

Pin 14 (Not Used)

Pin 14 is an open connection.

Pin 15 (Automation Cycle Stop Input)

Pin 15 is an input control signal that when enabled, can

be used by the automation control system as a redundant

signal to shut the ultrasound output off. This signal could

also be reconfigured through menu selections to function

as an automation end-of-weld control signal input.

Continued from Previous Page

Page 20

iQ Series

Ultrasonic Generator/Power Supply, Servo Systems, ES User’s Manual

Dukane Manual Part No. 403-587-00

Содержание ES

Страница 127: ...SECTION 8 Maintenance Page 121 Dukane Manual Part No 403 587 00 Section 8 Maintenance ...

Страница 137: ...SECTION 10 Contacting Dukane Page 131 Dukane Manual Part No 403 587 00 Section 10 Contacting Dukane ...

Страница 171: ...Index Page 165 Dukane Manual Part No 403 587 00 Index ...