RS4203 Manual

Chapter 14 – Maintenance Guide

Rev 32, 01/11/13

Copyright © 2013, Tipper Tie, Inc., All rights reserved

88

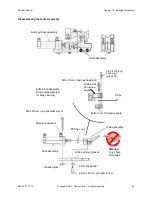

To add oil to a lubricator, follow these steps:

1. Ensure that the air supply is shut off and locked out and remove the filler plug.

2. Fill with oil to the level mark and replace the plug.

3. Turn on the air supply to the machine and turn the needle valve located on the top of the

lubricator

counterclockwise

until the desired flow is achieved.

4. Monitor the rate of oil flow into the system using the sight glass on the top of the lubricator.

Lubricator Drip Rates

•

The preferred flow of oil for the main lubricator is one (1) drop of oil for every 10-15 machine cycles.

•

The conveyor air motor lubricator uses a drop rate of one (1) drop for every 15-20 cycles.

•

The voider rotary actuator lubricator uses a drop rate of one (1) drop for every 10 cycles.

14.6 Conveyor Maintenance

The conveyor hitch bar assembly attaches the conveyor to the movable voider. The fasteners that attach

to the conveyor need to be checked periodically for tightness.

The bearings that support the conveyor drive roller and the rollers in the conveyor roller carriage should

be greased every day.

The conveyor air motor is maintenance free and does not have to be lubricated or disassembled for

periodic maintenance. However, periodically check the tightness of the mounting bolts and drive shaft

connections. Check the air mufflers for accumulated oil and dirt. A clogged air muffler will adversely affect

the motor’s operation by restricting the exhausted air. If the mufflers are clogged, clean or replace them.

14.7 Mechanical Lubrication

Each day, prior to operating the machine, lubricate all of the grease fittings except the voider actuator

bearings, the conveyor drive roller bearings, and the conveyor idler roller bearings.

Once each week, lubricate the voider actuator and conveyor drive roller bearings and the conveyor idler

roller.

Caution

: Do not apply too much grease to these fittings. Excessive grease in these closed units will

clog the bearings and cause the assemblies to run intermittently or stop completely.

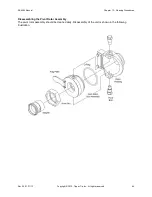

The following illustrations show the locations of the grease fittings and the service frequency.

Daily

Clipper Pivot Block

(2 fittings)