RS4203 Manual

Chapter 13 - Cleaning Procedures

Rev 32, 01/11/13

Copyright © 2013, Tipper Tie, Inc., All rights reserved

81

Chapter 13 – Cleaning Procedures

13.1 Cleaning Overview

After the machine has been used or serviced, it must be cleaned to remove all food or other residue from

the food contact zone – the clipper, punch, die, gate, knife assembly and all other contact surfaces.

Check all other machine surfaces and surrounding work stations for contamination. All surfaces must be

cleaned in accordance with current regulations and with recommended materials and procedures.

Warning

: Always disconnect and lock out the electrical supply, and

disconnect and lock out the air supply before cleaning the machine.

Warning

: Do not attempt to clean the machine unless the Control

Box door is securely closed.

Caution

: Do not use high-pressure spray to clean the operator interface. It should be washed with a soft

cloth or sponge and rinsed with a low-pressure water spray. Then cover it with a plastic bag.

Caution

: Do not use abrasive pads or cleaners to clean the touchscreen or the covers and doors.

Caution

: Use plastic to cover and protect all electrical components, electrical connections, motors and

air lines from water and cleaning solutions. After cleaning by hand, cover the operator interface assembly

with a plastic bag.

Caution

: The use of excessively caustic sanitizer solutions will adversely affect the finish of many of the

components on the machine.

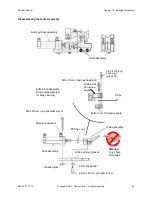

13.2 Disassembly for Cleaning

Disassemble the machine for cleaning as follows:

1. Press stop on the system control console (stopping all machine functions) and prepare to perform

all lockout procedures).

2. Open and close main guard to reset gates and voiders.

3. Press emergency stop button located on the user interface panel.

4. Turn off the main air supply, by shutting the yellow cutoff valve. Turn-off the main electrical power

switch, which is mounted on the control cabinet.

5. Remove clips, and loops.

6. Disconnect the electrical supply from the machine.

7. Disconnect the filler control cable from both machines and replace the water tight covers on the

RS4203. Store cables in a clean, dry place.

8. Disconnect the fill tube from the filler.

9. Disconnect the main air supply.

10. Remove the filling horn.

11. Loosen locating screw, remove adaptor fill tube and remove rotor from the turret.

12. Open the main guard and release the conveyor tension clamps.

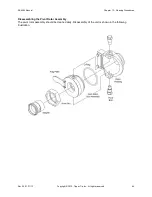

13. Remove and disassemble the skin brake assembly.

14. Remove tri-clover clamp fitting.

15. Remove the knife blade assembly.

16. Open the main guard and release the conveyor tension clamps. Remove the conveyor belt.

Warning

: Disassembly of the knife assembly can be dangerous due to the very

sharp knife edge. Exercise extreme caution.