15. Configure motors, encoders and limit switches in software

5. Configuring motors to move in the correct direction

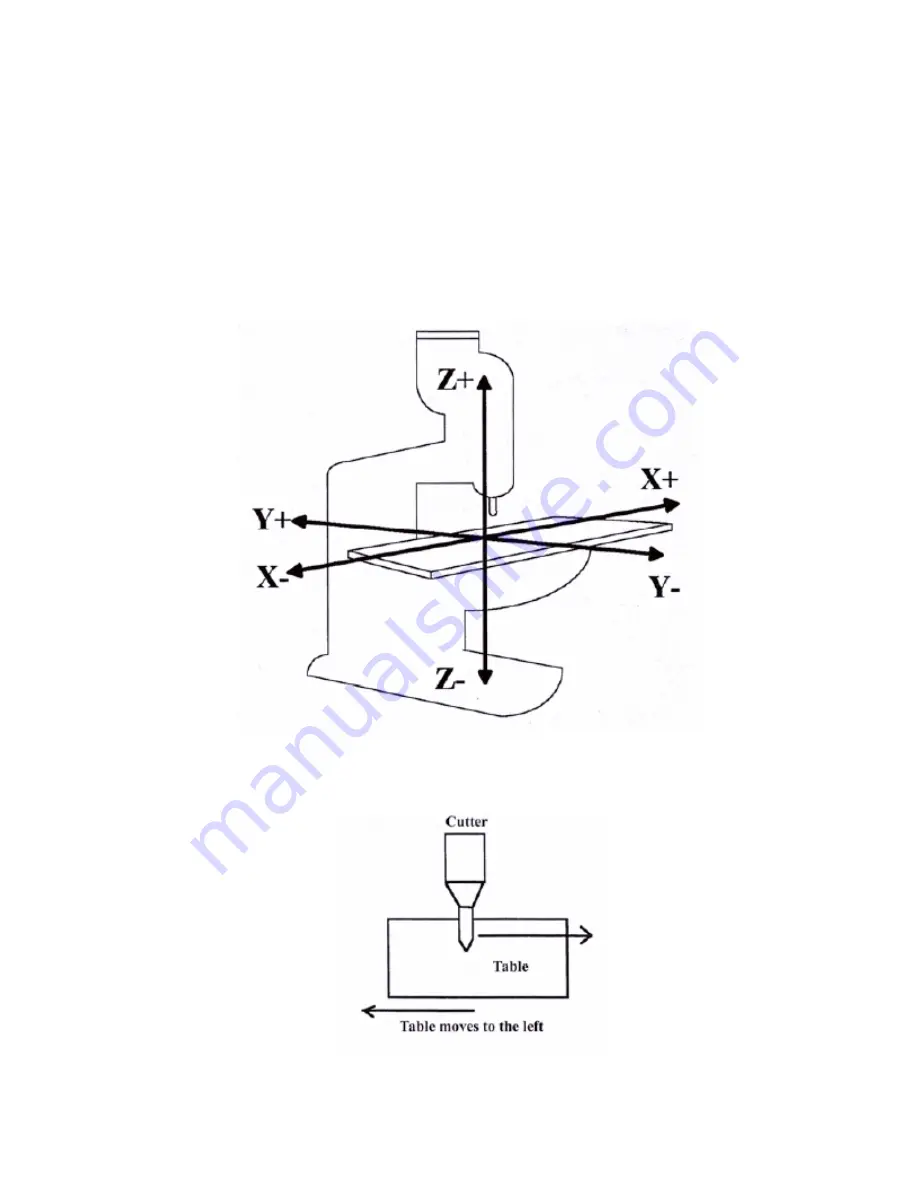

It is important to understand that

correct motor direction is determined by the motion of the tool relative to the part, this is not

necessarily the same as the motion of the table. For axes that move the table while the tool

remains stationary such as the X & Y axes on a typical Bridgeport type knee mill, the table

motion is the opposite of the “tool motion”. For axes that move the tool, such as the quill on

a knee mill, axis motion is the same as the tool motion. The illustrations below describe this

concept.

Correct tool motion for each axis

Difference between table motion and tool motion on X axis of knee mill

In the above illustration, the tool is moving in the X+ direction relative to the part

while the table moves to the left.

Содержание GPIO4D

Страница 38: ...16 Wiring Auxiliary Sub systems 3 Spindle Wiring Spindle Contactor Wiring...

Страница 39: ...16 Wiring Auxiliary Sub systems 4 Spindle Inverter Wiring AutomationDirect GS2...

Страница 59: ...12 Counts differ on homing 13 Option not available 14 Parameter missing 15 Position error 16 FPWOM...