6. Configuring CNC11 For Bench Testing

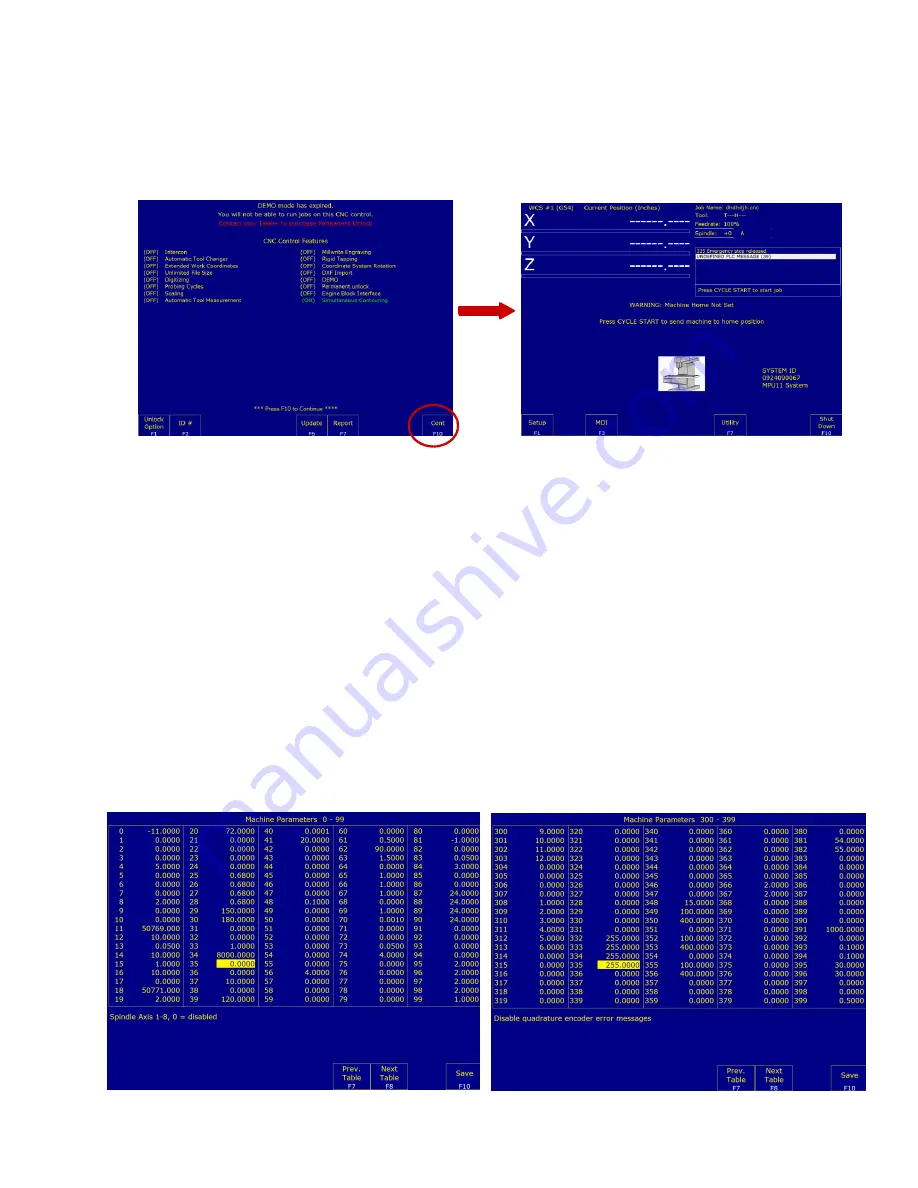

If CNC11, Windows and your network have been configured correctly, you should see the

screen below. Press F10 to continue to the main screen. If CNC11 does not start because it

timed out waiting for the MPU11, see Appendix A – Troubleshooting Communication Errors”

Initial Screen on Power Up Main Screen

To do the bench testing you will need to temporarily disable the fault protection logic built

into CNC11 and the PLC program. CNC11 monitors the signal levels of all configured

hardware such as jog panels and encoder inputs and will generate a fault if any hardware

does not respond as expected or if any channel of any encoder is not at it's expected

signal level. In addition, the GPIO4D Basic PLC program contains default logic that

monitors the inputs for Limit Switches (inputs 1-8), Lube Fault(input9), Spindle Fault

(input10), Estop (input11), and Axis Drive Faults (inputs 17-20). If ANY of these inputs are

open and a fault will be issued.

1. Disable encoder faults in CNC11

To disable encoder faults for the spindle encoder input

and the first 8 encoder inputs, set parameter 35 to 0 and parameters 332-335 to a value of

255 and press F10 to save. Use F7/F8 to page down/up though the parameter pages as

needed.

To navigate to the parameter menu from the main screen press:

F1-Setup->F3 -Config (pw = 137)->F3 Parms

Содержание GPIO4D

Страница 38: ...16 Wiring Auxiliary Sub systems 3 Spindle Wiring Spindle Contactor Wiring...

Страница 39: ...16 Wiring Auxiliary Sub systems 4 Spindle Inverter Wiring AutomationDirect GS2...

Страница 59: ...12 Counts differ on homing 13 Option not available 14 Parameter missing 15 Position error 16 FPWOM...