2-22

2002 Buell P3: Chassis

HOME

ASSEMBLY

1.

See

Figure 2-31.

Check piston assembly components.

a. Small end of spring (1) sits behind primary cup (2).

Large side of primary cup faces spring.

b.

Secondary cup (3) sits within ridge at middle of pis-

ton (4).

2.

Insert piston assembly, spring first, into master cylinder.

Secure with a

new

snap ring (6).

3.

Install ridge on boot (5) into groove on piston (4).

4.

See

Figure 2-28.

Install front brake hand lever.

a. Align hole in lever (3) with hole in master cylinder

assembly.

b.

Lubricate pivot bolt (2) with LOCTITE ANTI-SEIZE.

c.

Install pivot bolt through top of assembly. Tighten to

4-13

in-lbs

(0.5-1.5 Nm).

d. Install

nut (1) (metric). Tighten to 44-62

in-lbs

(5-

7 Nm).

5.

See

Figure 2-27.

Install front brake lamp switch (7).

a. Attach front brake switch with screw, washer and

lockwasher (1). Tighten to 7-13

in-lbs

(0.8-1.5 Nm).

b.

Test switch action. Tang (3) on switch must release

when hand lever (2) is moved.

INSTALLATION

1.

See

Figure 2-27.

Fasten master cylinder to handlebar by

installing clamp (2) and screws (1) (metric). Tighten to

80-120

in-lbs

(9-14 Nm).

1

1

WARNING

1

WARNING

Use only new black banjo washers (See Parts Catalog for

Part No.) with D.O.T. 4 brake fluid. Earlier silver banjo

washers are not compatible with D.O.T. 4 fluid and will

not seal properly over time. Failure to comply may

adversely affect braking ability and lead to brake failure

which could result in death or serious injury.

CAUTION

To avoid leakage, ensure that banjo washers, banjo bolt,

hydraulic brake line and master cylinder bore are com-

pletely clean.

2.

Connect brake line (5) to master cylinder using two

new

banjo washers (4) and banjo bolt (6) (metric). Tighten to

16-20 ft-lbs (22-27 Nm).

3.

See

Figure 2-32.

Verify brake lamp switches are secure.

Attach wires to switches.

4.

Install mirror parallel to handlebars.

5.

See

Figure 2-27.

Remove the two master cylinder cover

screws (3), cover and cover gasket.

6.

See

Figure 2-33.

With the master cylinder in a level posi-

tion, add

D.O.T. 4 BRAKE FLUID

. Bring fluid level to

within 0.125 in. (3.2 mm) of molded boss inside front

master cylinder reservoir.

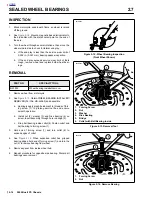

Figure 2-31. Piston Assembly

Figure 2-32. Brake Lamp Switch Connectors

Figure 2-33. Brake Fluid Level

6491

1.

Spring

2.

Primary Cup

3.

Secondary Cup

4.

Piston

5.

Boot

6.

Snap Ring

1

2

3

4

6

5

Connectors

6569

Brake Fluid Level

a0214x2x

Содержание 2002 P3

Страница 2: ......

Страница 17: ...A 15 Appendix A Tools HOME ...

Страница 32: ...C 3 Appendix C Metric Conversions HOME ...

Страница 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Страница 75: ......

Страница 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Страница 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Страница 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Страница 146: ......

Страница 147: ......

Страница 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Страница 225: ......

Страница 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Страница 258: ......

Страница 259: ......

Страница 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Страница 281: ......

Страница 327: ......

Страница 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Страница 399: ...SUBJECT PAGE NO A 1 TOOLS A 1 B 1 ELECTRICAL CONNECTORS B 1 C 1 METRIC INFORMATION C 1 Table Of Contents APPENDICES ...

Страница 400: ...Product 1 2 ...