3-38

2002 Buell P3: Engine

HOME

Fitting Cylinder to Piston

Since pistons cannot be accurately measured with standard

measuring instruments, the bore sizes must be measured.

Bore sizes are listed in

Table 3-10.

Example: A 0.005 in.

(0.127 mm) oversize piston will have the proper clearance

with a bore size of 3.502 in. ± 0.0002 in. (88.951 mm ±

0.0051 mm).

Boring and Honing Cylinder

When cylinder requires oversize reboring to beyond 0.030 in.

(0.762 mm), the oversize limit has been exceeded and cylin-

der must be replaced.

1.

Bore cylinder with gaskets and torque plates attached.

Bore to 0.003 in. (0.076 mm) under the desired finished

size.

2.

Hone the cylinder to its finished size using a 280 grit rigid

hone followed by a 240 grit flexible ball hone. Honing

must be done with the torque plates attached. All honing

must be done from the bottom (crankcase) end of the

cylinder. Work for a 60° crosshatch pattern.

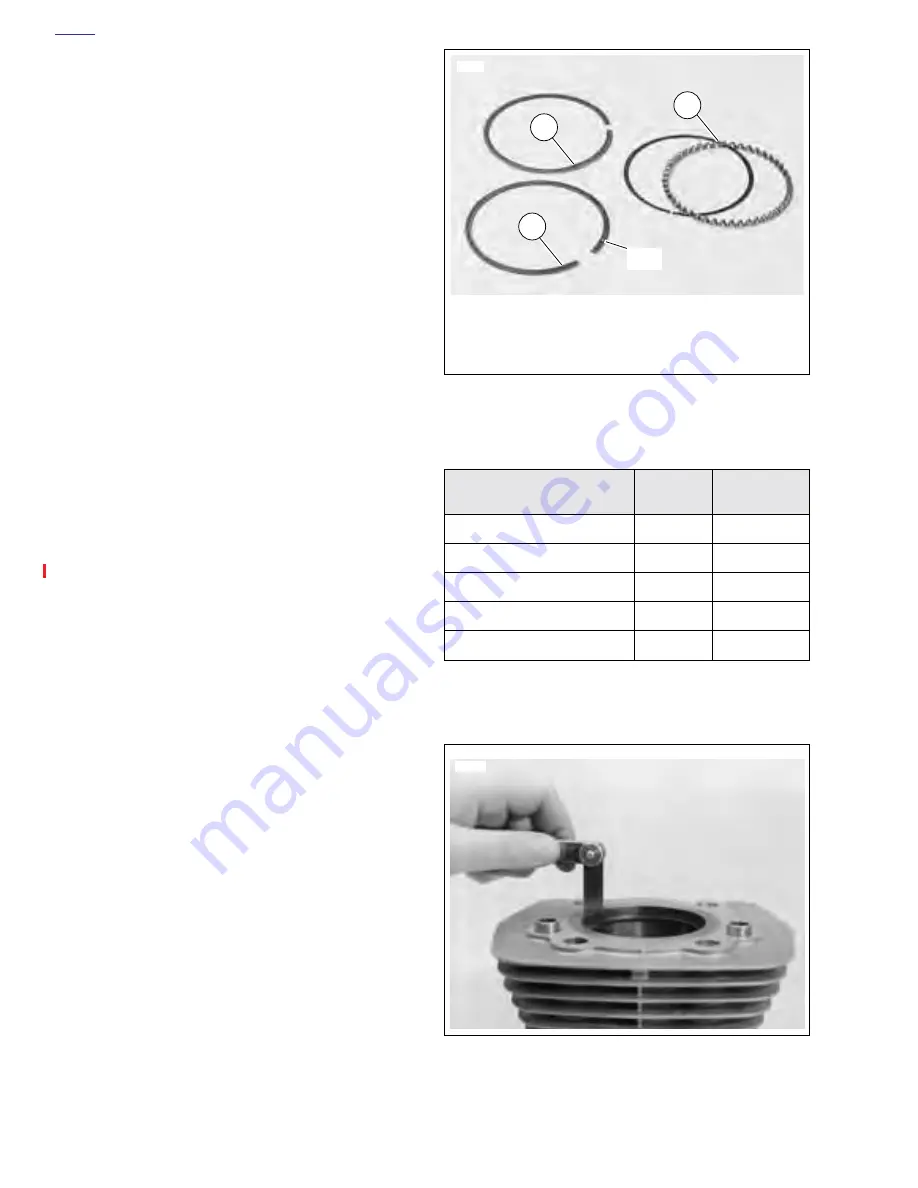

Fitting Piston Rings

See

Figure 3-71.

Piston rings are of two types: compression

and oil control. The two compression rings are positioned in

the two upper piston ring grooves. The dot on the second

compression ring must face upward. Ring sets are available

to fit standard and oversize pistons.

Piston ring sets must be properly fitted to piston and cylinder:

1.

See

3.1 SPECIFICATIONS

. See

Figure 3-72.

Place pis-

ton in cylinder about 1/2 in. (12.7 mm) from top. Set ring

to be checked squarely against piston as shown. Check

end gap with thickness gauge.

NOTE

See

SERVICE WEAR LIMITS

for end gap dimensions. Do

not file rings to obtain proper gap.

Figure 3-71. Piston Rings

Table 3-10. Final Cylinder Bore Sizes

BORE SIZES

IN.

MM

Standard bore*

3.4978 in.

88.8441 mm

0.005 in. OS bore (0.127 mm)

3.502 in.

88.951 mm

0.010 in. OS bore (0.254 mm)

3.507 in.

89.078 mm

0.020 in. OS bore (0.508 mm)

3.517 in.

89.332 mm

0.030 in. OS bore (0.762 mm)

3.527 in.

89.586 mm

*All bore sizes + 0.0002 in. (0.0051 mm)

Figure 3-72. Measuring Ring End Gap

1.

Top Compression Ring – Install either side up

2.

Second Compression Ring – Install dot toward

top

3.

Oil Control Rings

2

1

3

6612

Dot

2783a

Содержание 2002 P3

Страница 2: ......

Страница 17: ...A 15 Appendix A Tools HOME ...

Страница 32: ...C 3 Appendix C Metric Conversions HOME ...

Страница 41: ...1 8 2002 Buell P3 Maintenance HOME NOTES ...

Страница 75: ......

Страница 111: ...2 36 2002 Buell P3 Chassis HOME NOTES ...

Страница 143: ...2 68 2002 Buell P3 Chassis HOME NOTES ...

Страница 144: ...2002 Buell P3 Chassis 2 69 HOME ...

Страница 146: ......

Страница 147: ......

Страница 223: ...3 76 2002 Buell P3 Engine HOME NOTES ...

Страница 225: ......

Страница 256: ...2002 Buell P3 Fuel System 4 31 HOME ...

Страница 258: ......

Страница 259: ......

Страница 279: ...5 20 2002 Buell P3 Electric Starter HOME NOTES ...

Страница 281: ......

Страница 327: ......

Страница 398: ...2002 Buell P3 Electrical 7 71 HOME ...

Страница 399: ...SUBJECT PAGE NO A 1 TOOLS A 1 B 1 ELECTRICAL CONNECTORS B 1 C 1 METRIC INFORMATION C 1 Table Of Contents APPENDICES ...

Страница 400: ...Product 1 2 ...