81

PISTON PIN

Measure the piston pin diameter at each end and in the

center. Acceptable piston pin measurement must be

within 0.8659-0.8661 in. If any measurement varies by

more than 0.001 in., the piston pin and bearing must be

replaced as a set.

CWI-079

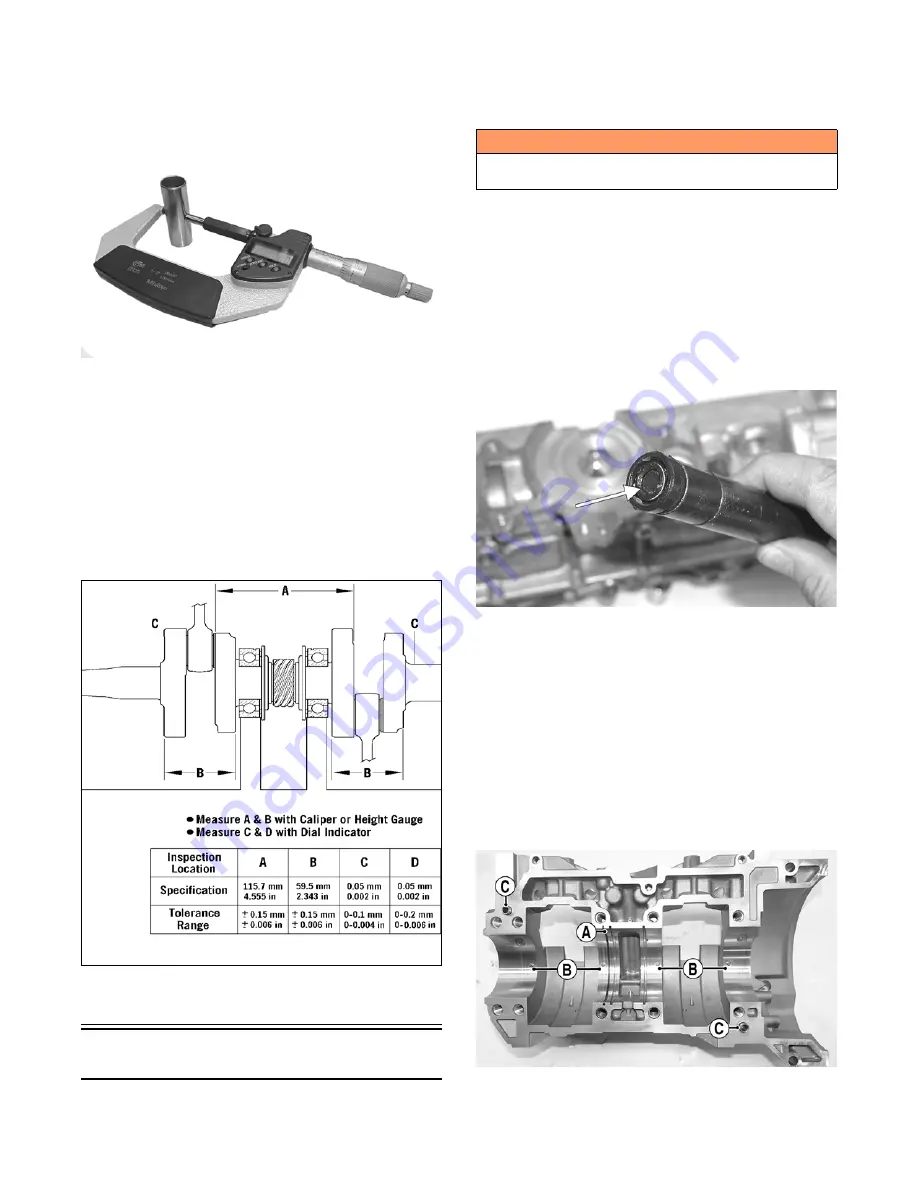

CRANKSHAFT RUNOUT

1. Using the V Blocks, support the crankshaft on the

surface plate.

NOTE: The V blocks should support the crankshaft

on the middle bearings.

2. Mount a dial indicator and base on the surface plate.

Position the indicator contact point against the crank-

shaft location points C and D. Zero the indicator and

rotate the crankshaft slowly. Note the amount of

crankshaft runout (total indicator reading).

0747-810

3. If runout exceeds any of the checkpoints, the crank-

shaft must be either straightened or replaced.

Assembling

NOTE: The use of new gaskets and seals is recom-

mended when assembling the engine.

NOTE: Prior to assembling the engine, use parts

cleaning solvent and compressed air and thoroughly

clean the threaded holes of the crankcase and cylin-

ders to properly tighten.

NOTE: When the use of a lubricant is indicated, use

Arctic Cat C-Tec2 engine oil.

1. Apply a thin coat of grease to the inner seal lips of

the water pump seal.

2. Using the seal driver, position the inner water pump

shaft seal onto the seal driver and gently tap the seal

down into position.

NOTE: Grease must be applied to the lips of the

inner seal before installation.

MS986A

NOTE: The seal must be installed with its spring

side towards the crankshaft.

3. Install the snap ring securing the inner seal in the

crankcase.

4. Using the seal driver, carefully install the outer water

pump seal. Gently tap the seal down into position

until it seats itself against its flange.

5. Secure the upper crankcase half upside-down on a

suitable support; then install the C-ring (A), the four

bearing retaining pins (B), and the two crankcase

dowel pins (C).

CWI-027A

6. Apply a thin coat of Loctite 5900 Sealant to the

entire bottom half of the crankcase sealing surface.

! WARNING

Always wear safety glasses when drying components

with compressed air.

Содержание M 8000

Страница 1: ...www arcticcat com SERVICE MANUAL www arcticcat com...

Страница 42: ...41 500cc_2A_15...

Страница 50: ...49 600_14_2...

Страница 58: ...57 800_12_2...

Страница 155: ...154 Troubleshooting Servomotor SERVO1A16...

Страница 156: ...155 SERVO2rv16...

Страница 193: ...192 0747 414 M 141 High Country Models...

Страница 209: ...208 NOTES...

Страница 210: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2260 847...