62

FS270

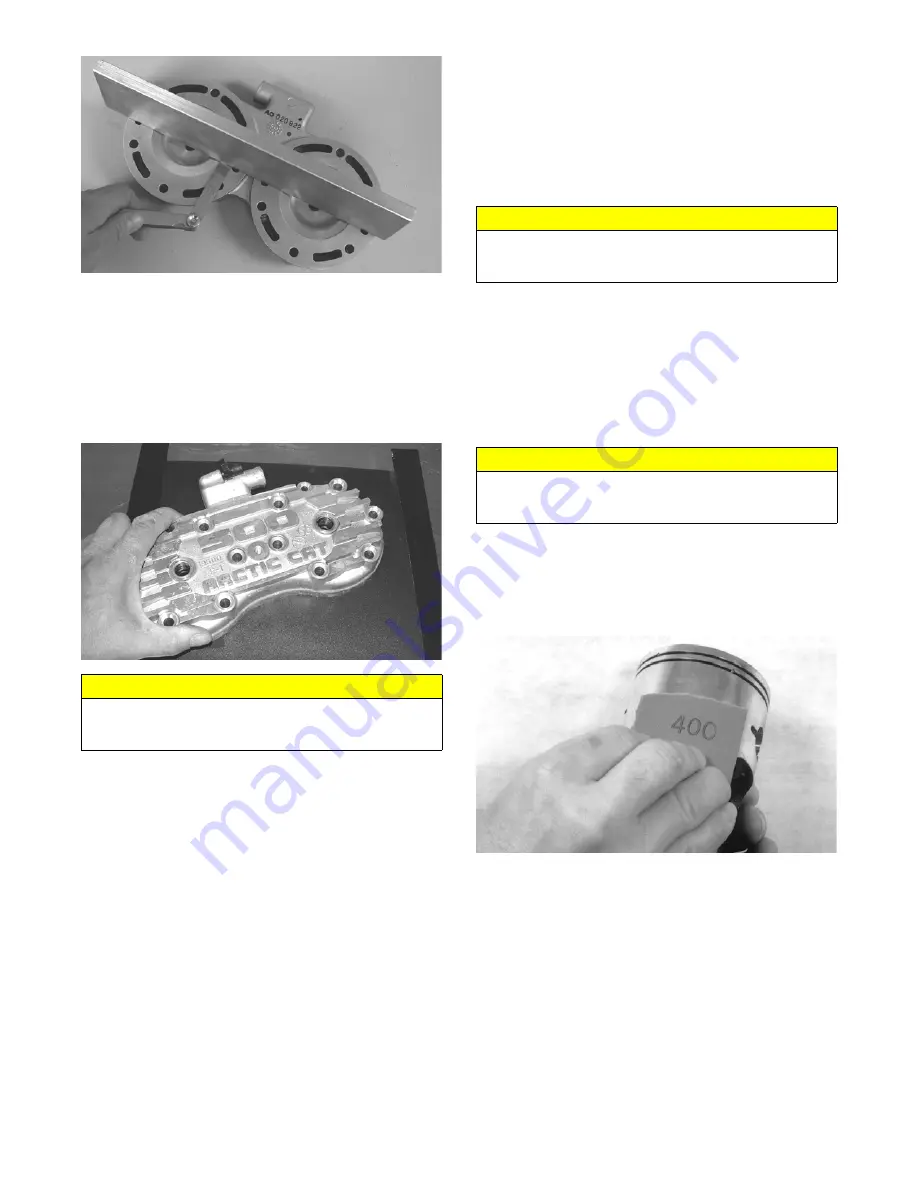

4. Place the cylinder head on a Surface Plate covered

with #400 grit wet-or-dry sandpaper. Using light

pressure, move each cylinder head in a figure eight

motion. Inspect the sealing surface for any indication

of high spots. A high spot can be noted by a bright

metallic finish. Correct any high spots before assem-

bly by continuing to move the cylinder head in a fig-

ure eight motion until a uniform bright metallic

finish is attained.

CM018

CYLINDERS

1. Using a non-metallic carbon removal tool, remove

carbon buildup from the exhaust ports.

2. Wash the cylinders in parts-cleaning solvent.

3. Inspect the cylinders for pitting, scoring, scuffing,

and corrosion. If marks are found, repair the surface

with a Ball Hone and honing oil.

NOTE: To produce the proper 45° crosshatch pat-

tern, maintain a low drill RPM. If honing oil is not

available, use a lightweight, petroleum-based oil.

Thoroughly clean the cylinders after honing using

detergent soap and hot water and dry with com-

pressed air; then immediately apply oil to the cylinder

bores. If a bore is severely damaged or gouged, the

cylinder must be replaced.

4. Place the head surface of each cylinder on the sur-

face plate covered with #400 grit wet-or-dry sandpa-

per. Using light pressure, move each cylinder in a

figure eight motion. Inspect the surface for any indi-

cation of high spots. A high spot can be noted by a

bright metallic finish. Correct any high spots before

assembly by continuing to move the cylinder in a fig-

ure eight motion until a uniform bright metallic fin-

ish is attained.

PISTON ASSEMBLY

1. Using a non-metallic carbon removal tool, remove

the carbon buildup from the dome of each piston.

2. Snap an old piston ring into two pieces; then grind

the end of the old ring to a 45° angle and to a sharp

edge. Using the sharpened ring as a tool, clean car-

bon from the ring-grooves. Be sure to position the

ring with its tapered side up.

3. Inspect each piston for cracks in the piston pin and

skirt areas.

4. Inspect each piston for seizure marks or scuffing.

Repair with #400 grit wet-or-dry sandpaper and

water or honing oil.

AN135

NOTE: If scuffing or seizure marks are too deep to

correct with the sandpaper, it will be necessary to

replace the piston.

5. Inspect the perimeter of each piston for signs of

excessive “blowby.” Excessive “blowby” indicates

worn piston rings or an out-of-round cylinder.

NOTE: If synthetic oil is being used, a certain

amount of “blowby” may be visible under normal use.

CRANKCASE

NOTE: The coolant temperature sensor must be

removed for this procedure.

1. Wash the crankcase halves in parts-cleaning solvent.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.

CAUTION

Improper cleaning of the ring-grooves by the use of the

wrong type of ring-groove cleaner will result in severe

damage to the piston.

Содержание M 8000

Страница 1: ...www arcticcat com SERVICE MANUAL www arcticcat com...

Страница 42: ...41 500cc_2A_15...

Страница 50: ...49 600_14_2...

Страница 58: ...57 800_12_2...

Страница 155: ...154 Troubleshooting Servomotor SERVO1A16...

Страница 156: ...155 SERVO2rv16...

Страница 193: ...192 0747 414 M 141 High Country Models...

Страница 209: ...208 NOTES...

Страница 210: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2260 847...