5/12/2017

TECH-538/D.W.O. 23160

Page 126 of 189

Spool Valve Cleaning (new standard flow manifold)

It is not recommended to service the new standard flow manifold. In normal conditions (i.e. high quality supply air,

healthy actuator) there will be minimal if any maintenance necessary on the spool valve. If unfavorable conditions

exist (i.e. poor supply air quality or if lubrication and sediment from the actuator is being exhausted through the

spool valve) it is recommended to replace the manifold or contact Westlock regarding service requests.

In extreme conditions, in case the user wants to proceed and service the manifold

, please contact Westlock before

doing in order to prevent warranties and guarantees to be voided.

The process to service it may become necessary to clean the spool valve to avoid operational failures due to valve

sticking and to maintain optimum positioner performance.

The positioner’s onboard filter should be replaced in Westlock premises whenever it gets clogged.

The filter’s original color is chalky white. A discolored filter may also indicate the need for an evaluation of the

air-supply quality.

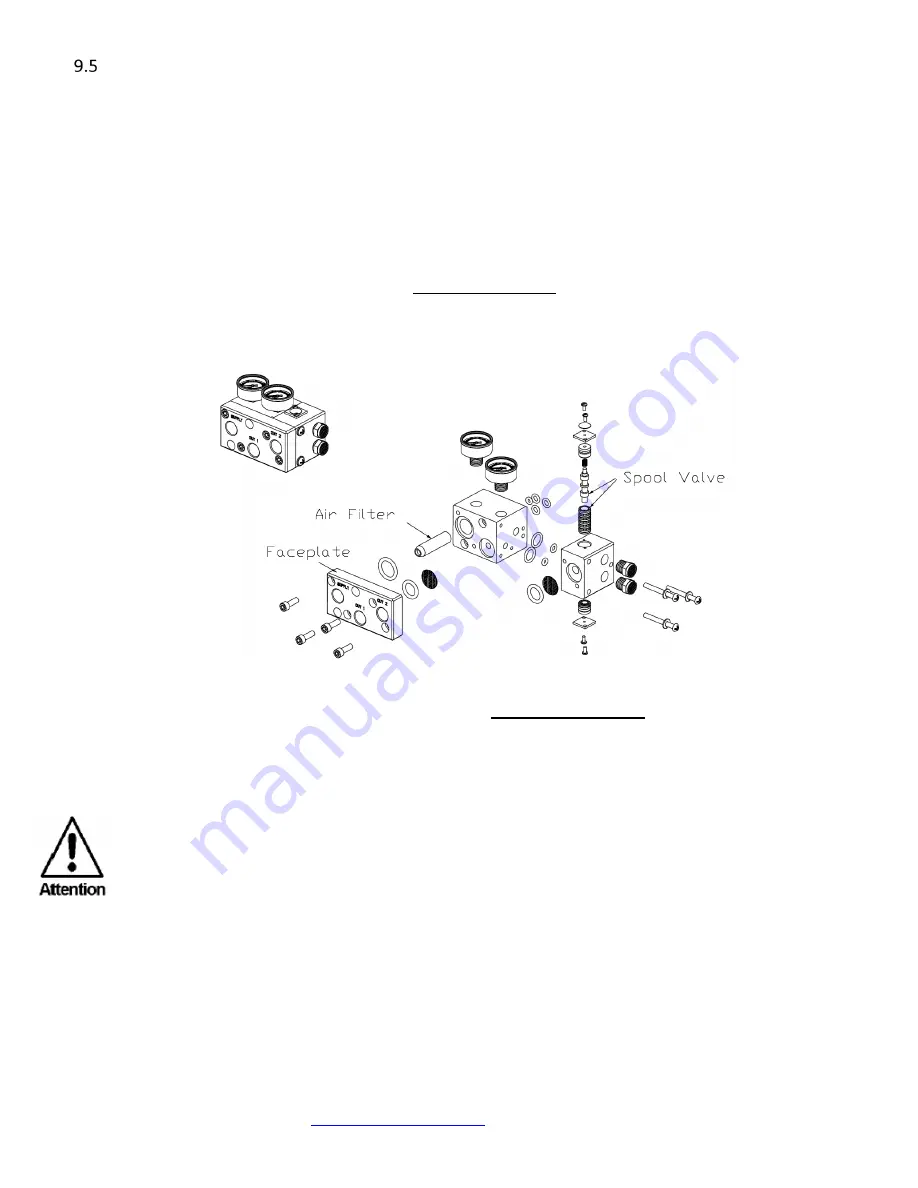

Figure 9-8– Diagram for the air filter and spool piece removal

To clean the spool valve, the spool piece needs to be removed in Westlock premises. Prior to removing the spool,

make sure the positioner is out of service and all air pressure has been bled-off the positioner and the actuator.

The spool piece and sleeve can be cleaned using any non-chlorinated cleaning solvent. To clean the spool, use a

clean lint free cloth. To clean the I.D. of the sleeve a polyester lint free clean room swab is recommended.

Important:

do not use an abrasive cleaner on the spool or sleeve. Never buff the spool or sleeve or use

crocus cloth, and never attempt to remove the sharp edges from the spool lands. These practices will

permanently damage the spool assembly and will affect the fit and action of the spool sleeve assembly.

Important:

the spool and sleeve assembly are sold as a precision matched set.

Spools are not interchangeable. To prevent mix-ups it is recommended that only one assembly be

cleaned at a time. In case mix-up happen contact factory for additional support.

Important:

after cleaning, gently insert the spool into the sleeve. Insert straight with a slight rotating

motion. Do not cock the spool. Make sure the spool spins and moves freely. After the spool valve is

cleaned and reassembled the positioner should recalibrated using the auto CAL function.

Important: This manifold was not designed to be serviced by the end user. Any maintenance executed outside

Westlock premises or an authorized Westlock technician may void the warranty provided by Westlock and its

representatives. In case of doubt consult Westlock about the correct procedure to follow.