5/12/2017

TECH-538/D.W.O. 23160

Page 114 of 189

A Calibration Error is returned during a Lo or Hi Calibration

•

For rotary actuators, the beacon may be assembled correctly (displaced of 90 degrees) or the

actuator may not have enough rotation. The positioner requires the actuator to stroke a minimum

of 45 degrees.

•

For linear actuators, the feedback magnet assembly needs to be ordered to match the stroke of the

actuator and the fail direction of the actuator (See figure x-1 & x-2). Check if the magnet center is

aligned with the actual 50% position of the actuator stroke (the mid-stroke point of the actuator’

stem).

The display shows the “Integrator Overflow” message

•

This message indicates that the positioner couldn’t reset the deviation between position and

setpoint even after applying the maximum internal power generated by the integral term of the

control algorithm. This condition may be temporary.

•

Make sure the valve – actuator is not stuck or locked.

•

Make sure that there is no air leakage in the actuator-positioner connections or if the working

pressure is too different (50%) from the calibrated pressure.

•

In case this error is permanent or intermittent, make sure that all the preliminary checks,

as described earlier in this section, have been performed. If the cause for the Integrator Overflow

error cannot be diagnosed, please contact Westlock for support.

ICoT does not turn on and / or the display does not show any information when energized

•

Check the voltage between the terminal point 1 and terminal point 2. It should be between 9V and

35V, otherwise there may be a problem with the power supply, barrier, protections,

bus terminators or cabling.

•

Locate the terminal strip and carefully disconnect it. Using an Ohmmeter check the resistance

between the terminal point 1 and terminal point 2. If the resistance is higher than 100 kOhms the

internal fuse may be blown. Contact Westlock for technical support.

Block tags on my application are different from the references on this manual

Generally, in a real application the blocks’ tags are going to be different from the default tags

referenced in this manual. A List of the default tags and its indexes is shown in the

(Section 8.5).

This may help to identify each block in the application.

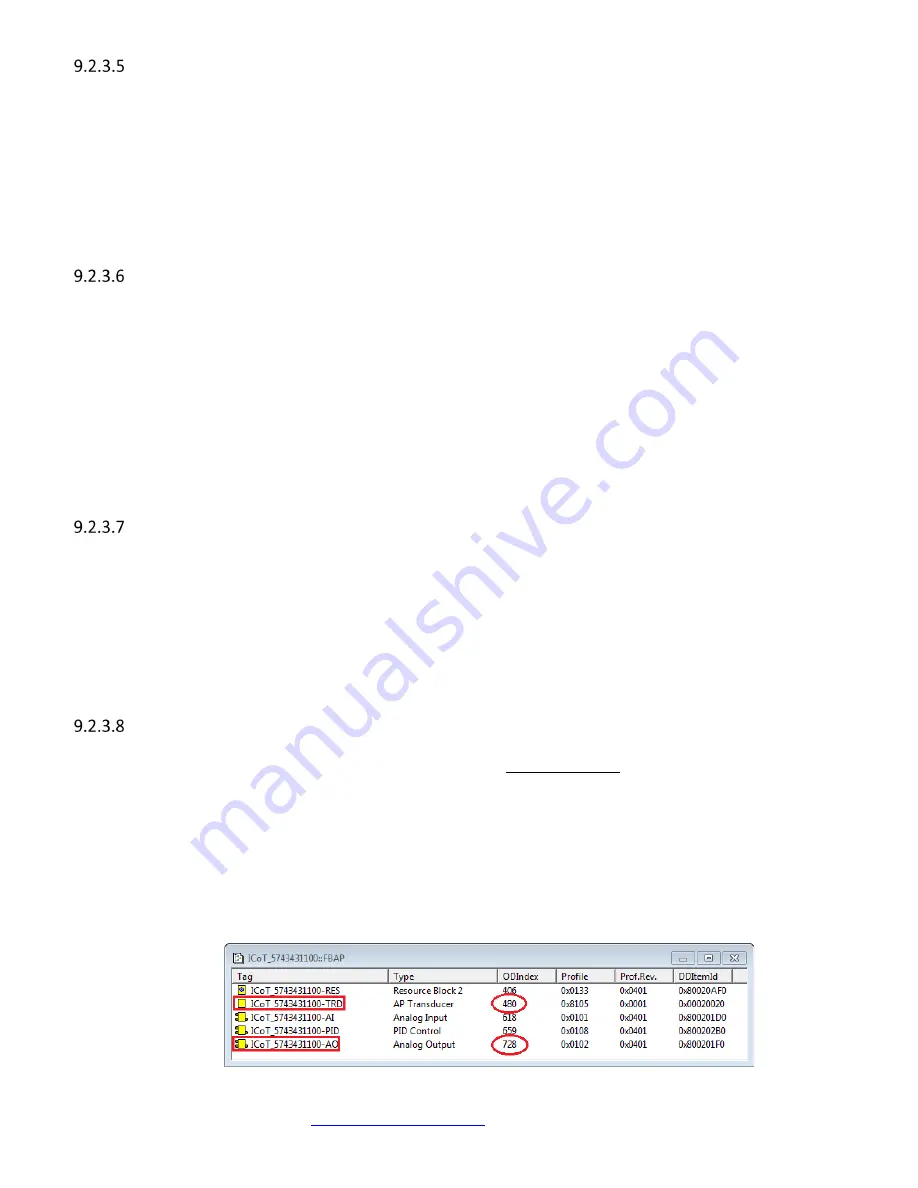

In the next picture there is an example showing the ICoT FF function block list in a FF Host system

where one can correlate the block tag with the physical block in the ICoT:

•

ICoT_5743431100-TRD

is the renamed transducer block tag (default tag: TRANSDUCER_WAPB2).

The block index or ODIndex is 480 (decimal).

•

ICoT_5743431100-AO

is the renamed AO tag (block index or ODIndex 728 - decimal).

Figure 9-5 – ICoT function block list shown by a FF Host system